Coupling service life testing equipment

A technology for testing equipment and couplings, applied in the field of coupling service life testing equipment, can solve problems such as the inability to meet a variety of coupling life tests, and achieve the effect of reducing test costs and reducing the number of purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

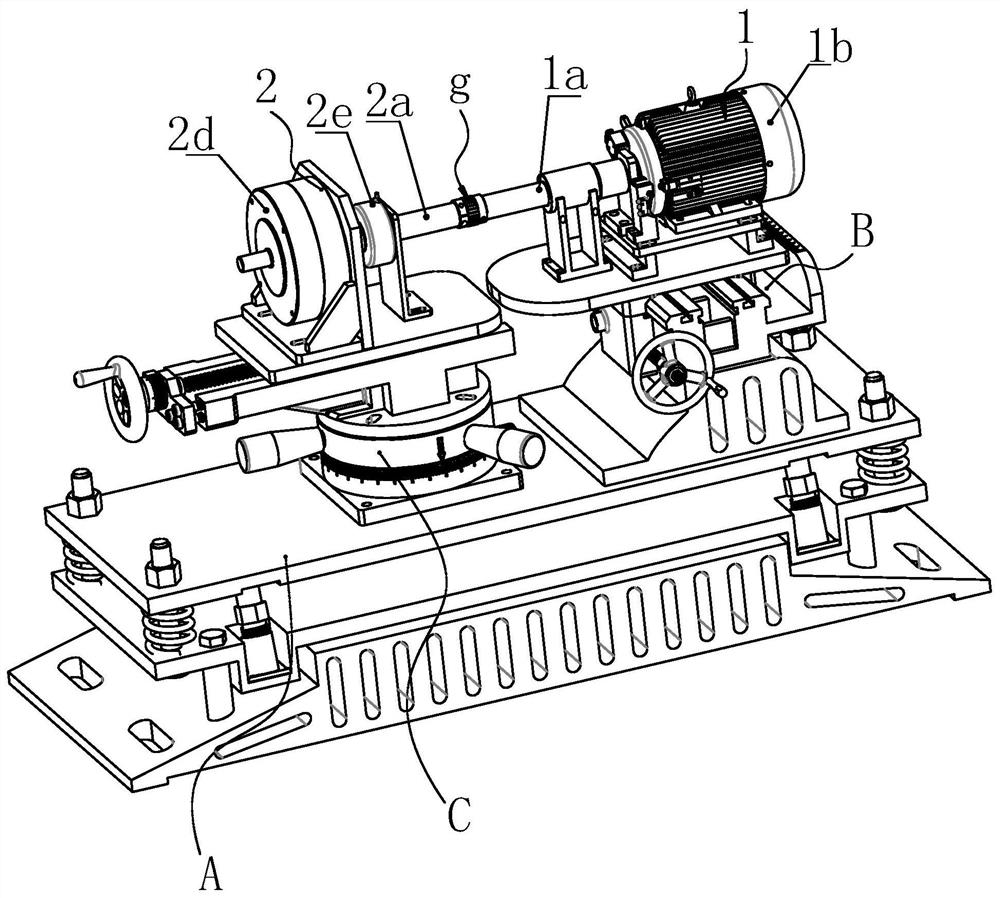

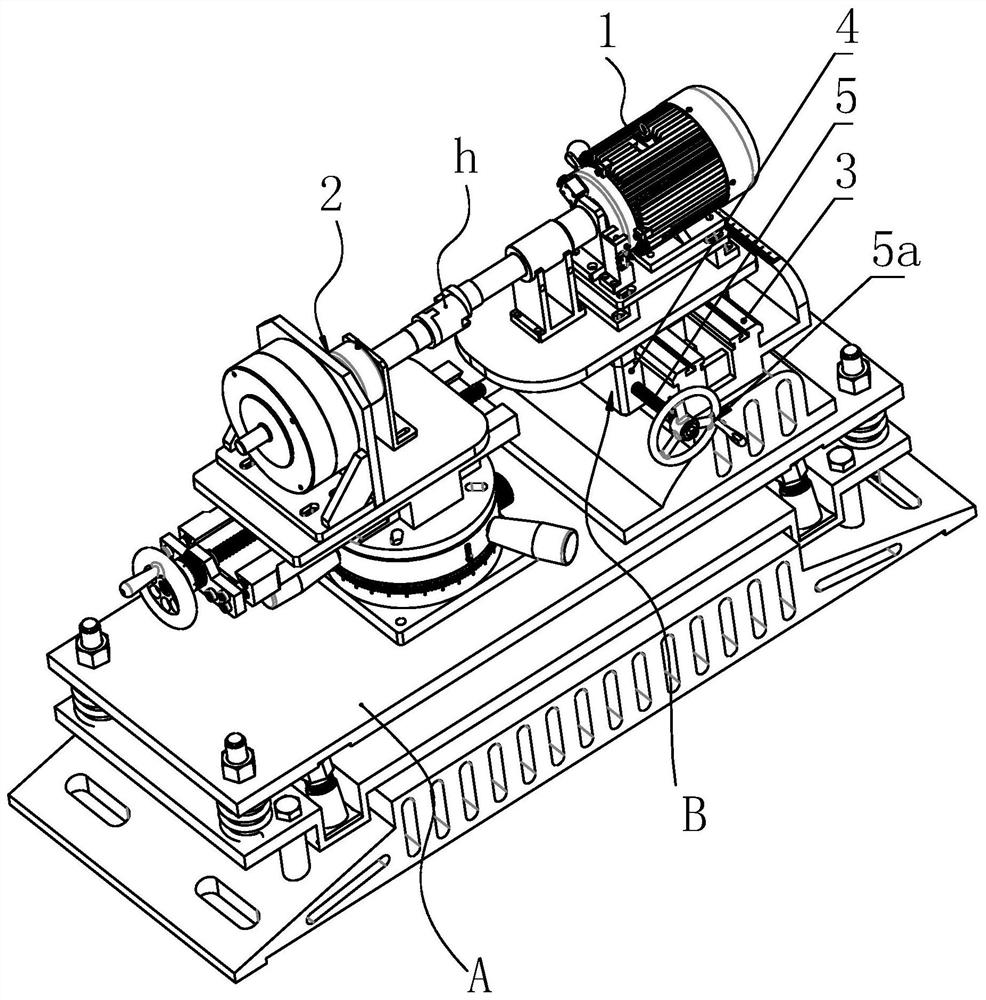

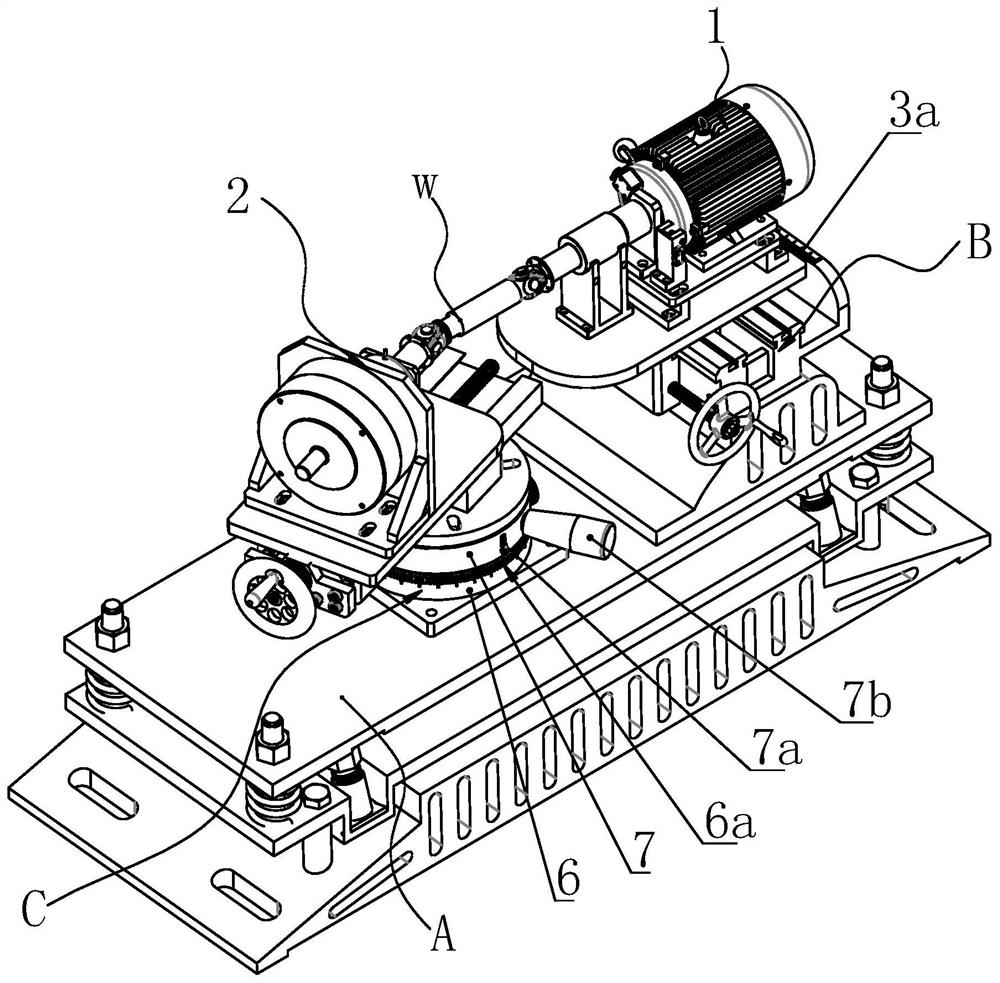

[0029] Such as Figures 1 to 3 As shown, a coupling service life testing equipment can be used to test the service life of three types of couplings. Its structure includes a device base A, a power end 1 with an output shaft 1a, and a load end with an input shaft 2a 2. The coupling to be tested is installed between the output shaft 1a and the input shaft 2a, the power end 1 provides output power, and the load end 2 provides torsion load. Wherein, the power end 1 is installed on the equipment base A through a lateral translation mechanism B, and the lateral translation mechanism B is used to adjust the radial deviation between the output shaft 1a and the input shaft 2a. The load end 2 is mounted on the equipment base A through a circular rotation mechanism C, which is used to adjust the angle between the output shaft 1a and the input shaft 2a.

[0030] Testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com