Firing method capable of controlling Jun porcelain furnace transmutation effect

A technology of kiln transformation and Jun porcelain, which is applied in the firing field of controllable Jun porcelain kiln transformation effect, and can solve problems such as difficult control and Jun porcelain difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

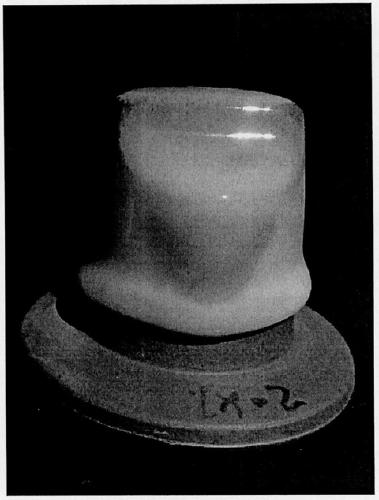

Image

Examples

Embodiment 1

[0022] 1. Glaze embryo selection: use the moon white glaze as the carrier, dry the glaze embryos with the moon white glaze applied to the kiln.

[0023] 2. Selection and processing of kiln glaze: 500g of copper oxide, 300g of calcite, 150g of zinc oxide, 30g of burnt talc, and 20g of tin oxide are mixed and put into a 1kg ball mill jar, and processed with 800g of water for 30 hours to obtain a particle size of 250 mesh. Glaze, and placed in a crucible to dry.

[0024] 3. Place the crucible containing the dried kiln-transformed glaze and the Jun porcelain glaze blank that needs to have a kiln-transformed effect horizontally.

[0025] 4. Firing method: In the first step, fire in a neutral or weakly oxidizing atmosphere for 3 hours to 950°C; in the second step, fire in a reducing atmosphere for 2 hours to 1080°C; in the third step, fire in a reducing atmosphere for 4 hours The fourth step is to fire to 1280°C in a neutral or weakly oxidizing atmosphere for 2 hours; the fifth ste...

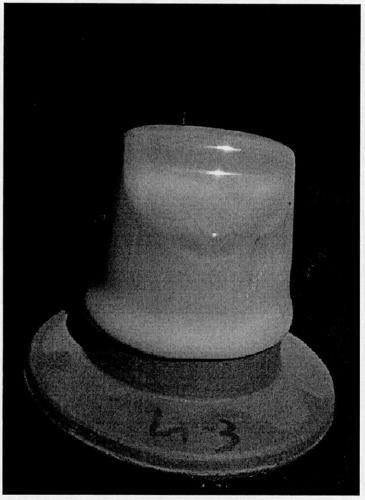

Embodiment 2

[0027] 1. Glaze embryo selection: use the sky blue glaze as the carrier, dry the glaze embryo with the sky blue glaze and put it in the kiln.

[0028] 2. Selection and processing of kiln-changing glaze: mix 600g copper oxide, 240g calcite, 100g zinc oxide, 50g burnt talc, and 10g tin oxide into a 1kg ball mill jar, add 800g water and process for 30 hours to obtain a particle size of 250 mesh Glaze, and placed in a crucible to dry.

[0029] 3. Place the crucible containing the dried kiln-transformed glaze and the Jun porcelain glaze blank that needs to have a kiln-transformed effect horizontally.

[0030] 4. Firing method: In the first step, fire in a neutral or weakly oxidizing atmosphere for 5 hours to 1050°C; in the second step, fire in a reducing atmosphere for 1 hour to 1120°C; in the third step, fire in a reducing atmosphere for 3 hours The fourth step is to fire to 1300°C in a neutral or weakly oxidizing atmosphere for 2 hours; the fifth step is to cool naturally to roo...

Embodiment 3

[0032] 1. Glaze embryo selection: use the sky blue glaze as the carrier, dry the glaze embryo with the sky blue glaze and put it in the kiln.

[0033] 2. Selection and processing of kiln glaze: 560g of copper oxide, 260g of calcite, 125g of zinc oxide, 40g of burnt talc, and 15g of tin oxide are mixed and put into a 1kg ball mill jar, and then processed with 800g of water for 30 hours to obtain a particle size of 250 mesh. Glaze, and placed in a crucible to dry.

[0034] 3. Place the crucible containing the dried kiln-transformed glaze and the Jun porcelain glaze blank that needs to have a kiln-transformed effect horizontally.

[0035] 4. Firing method: In the first step, fire in a neutral or weakly oxidizing atmosphere for 4 hours to 1000°C; in the second step, fire in a reducing atmosphere for 1.5 hours to 1100°C; in the third step, fire in a reducing atmosphere for 3.5 hours h firing to 1200°C; the fourth step, firing to 1290°C in a neutral or weakly oxidizing atmosphere f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com