Method for accurately forecasting in-furnace remaining time of hot rolled plate blanks

A slab, time technology, applied in the direction of instrumentation, comprehensive factory control, control/regulation system, etc., can solve problems such as inaccurate furnace temperature setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The invention provides a method for accurately predicting the remaining time of the hot-rolled slab in the furnace.

[0032] The method includes steps as follows:

[0033] (1) Statistical analysis of previous data: Statistical analysis is carried out on the tapping time intervals of different types of materials according to the slab length, width, and final rolling thickness, and the tapping interval process tables for different specifications of slabs are obtained;

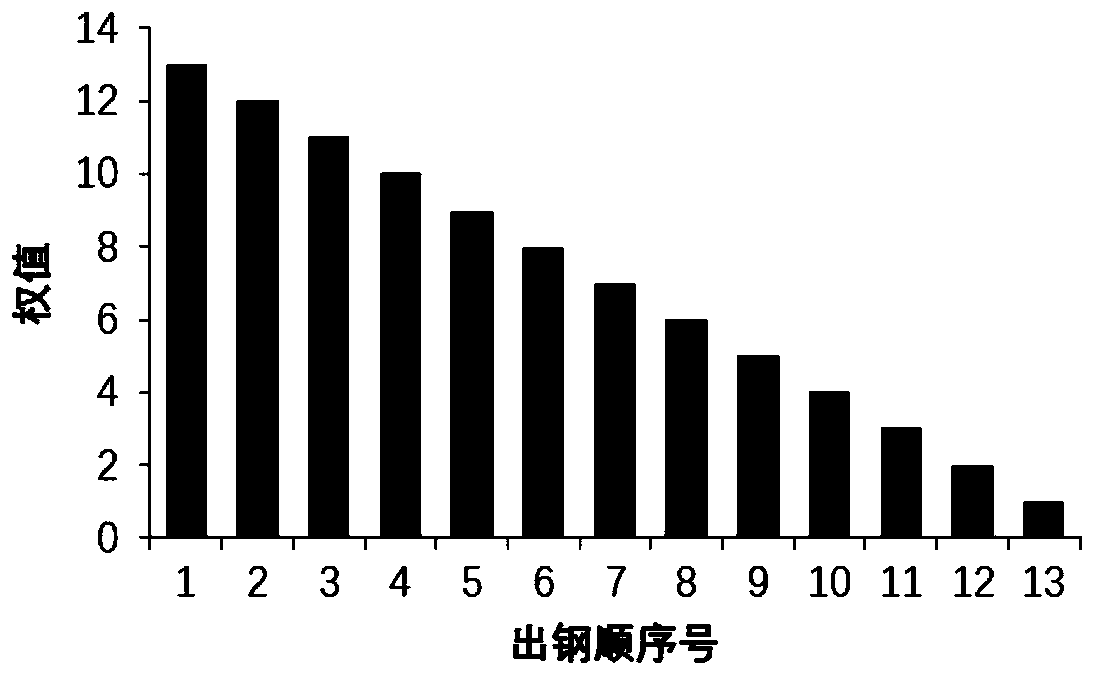

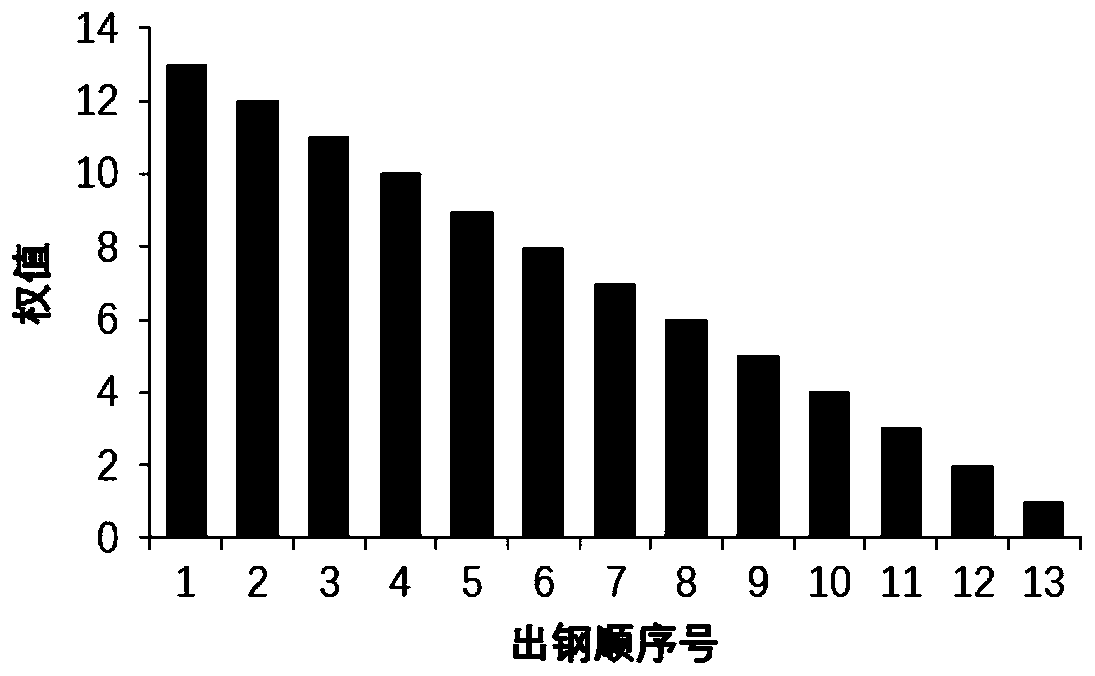

[0034] (2) Determining the firing sequence: traverse all furnace slabs in the furnace, sort according to the furnace loading sequence, and determine the firing sequence number of each slab;

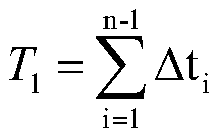

[0035] (3) Determine the time of a single slab in the furnace: predict the remaining time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com