A kind of cable insulation layer manufacturing device

A cable insulation and manufacturing device technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve problems such as poor production quality, and achieve the effect of reasonable structure and easy operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

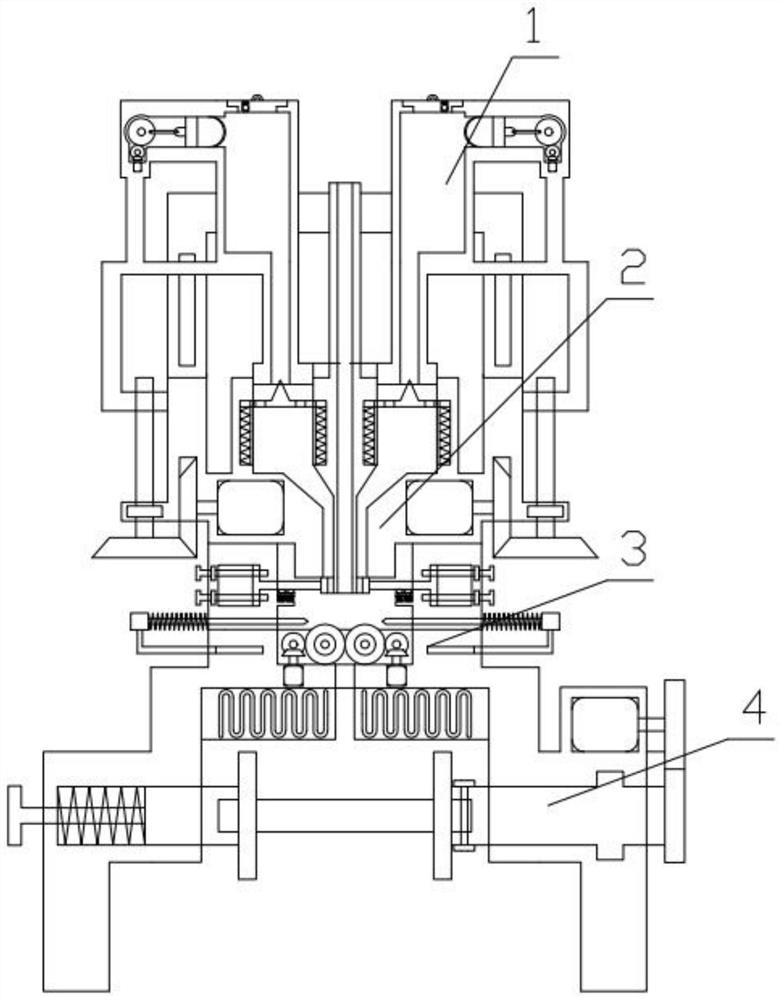

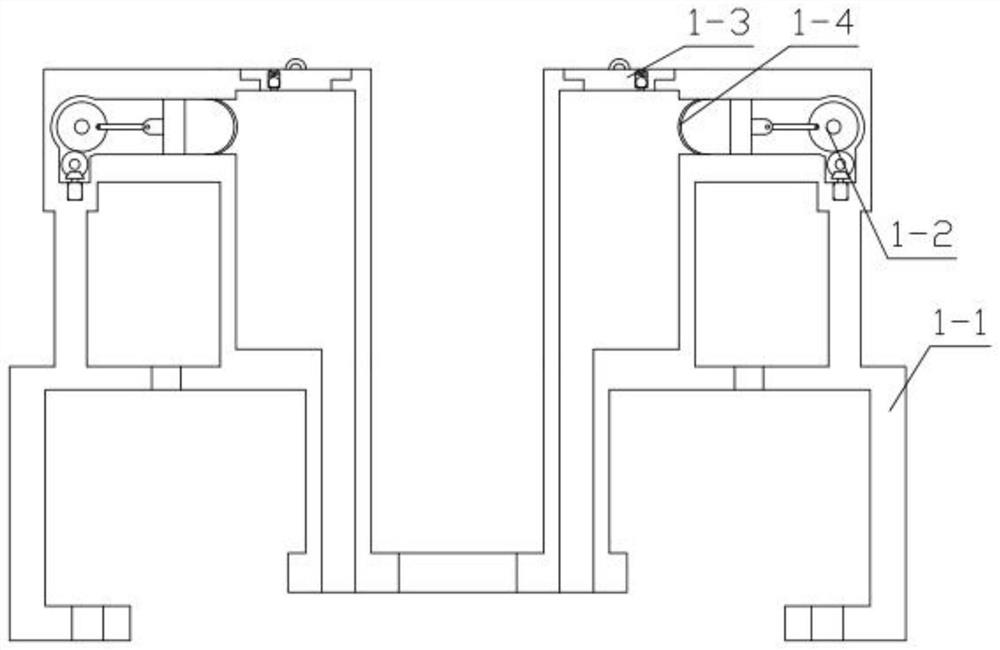

[0058] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21 illustrate this embodiment, the present invention relates to a Related, more specifically, it is a cable insulation layer manufacturing device, including a feeding mechanism 1, a material discharging mechanism 2, a cutting and hole adjustment mechanism 3, and a bottom comprehensive mechanism 4. This device can be pressurized and the mold can be replaced. It has the function of cutting, winding, and condensation plasticity. The device has a reasonable structure and is easy to operate.

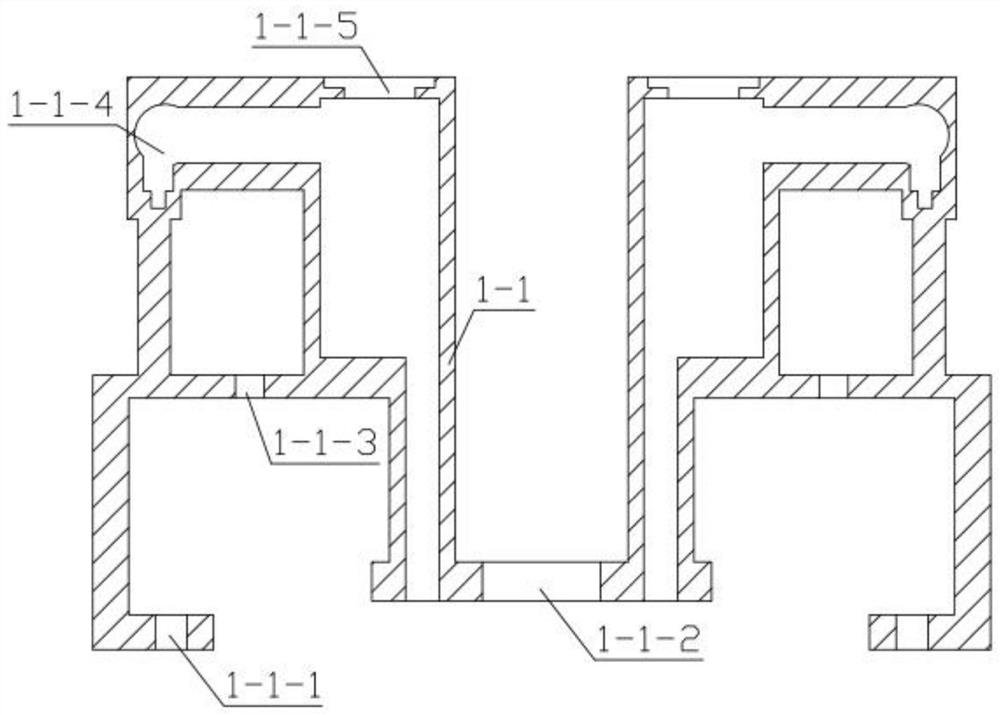

[0059] The feeding mechanism 1 includes a feeding housing 1-1, a pressurizing structure 1-2, a sealing cover 1-3, an elastic pressure film 1-4, and the feeding housing 1-1 and the pressurizing structure 1-2 Through the pressurization groove 1-1-4 fixed connection, the feeding shell 1-1 and the sealing cover 1-3 are meshed through the cover adapting threaded hole 1-1-5, and the elastic pressu...

specific Embodiment approach 2

[0084] Combine below figure 1 , 2 . To further illustrate, there are two condensing elements 4-2, and their positions are relatively symmetrical.

specific Embodiment approach 3

[0086] Combine below figure 1 , 2 . To further illustrate, there are two cutting and hole-adjusting mechanisms 3, and their positions are relatively symmetrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com