Structure integrating side pieces, rear pieces and back straps for bras and production process of structure

A back and one-piece technology, applied in bras, applications, clothing, etc., can solve the problems that are not good for women's health, easy to show traces at the joints, and unsightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

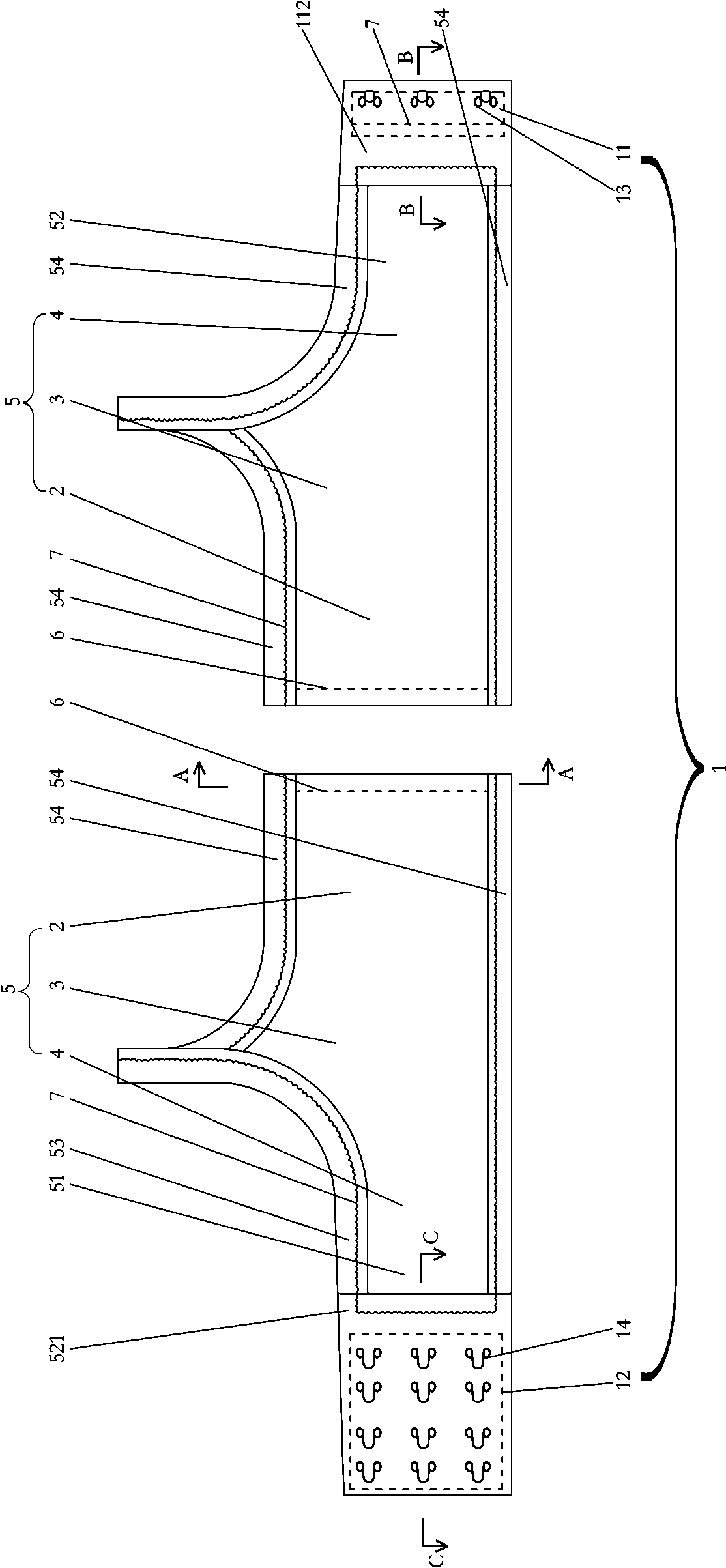

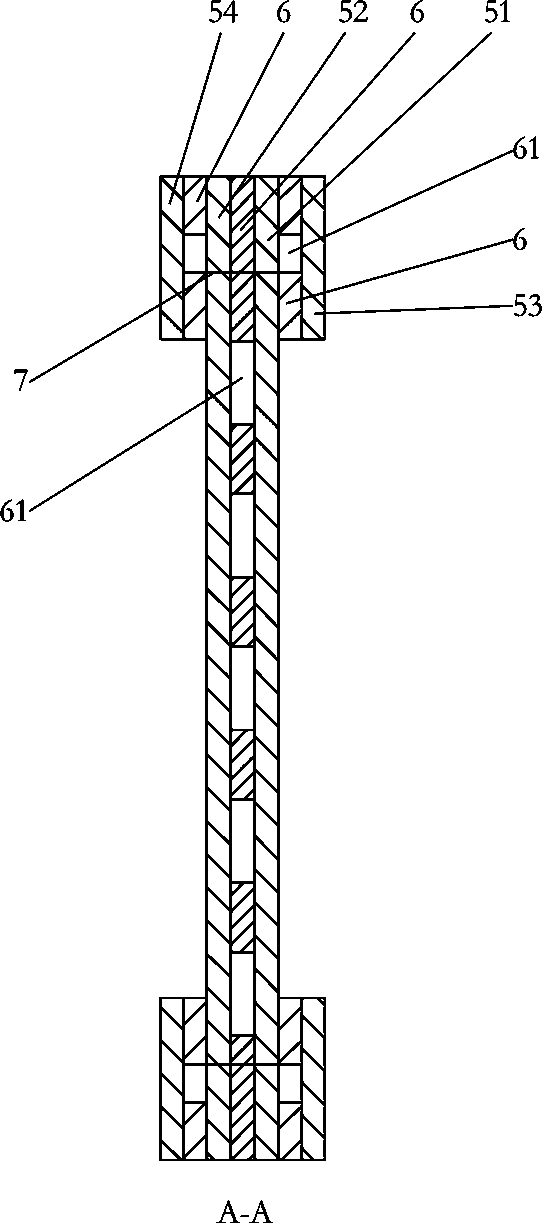

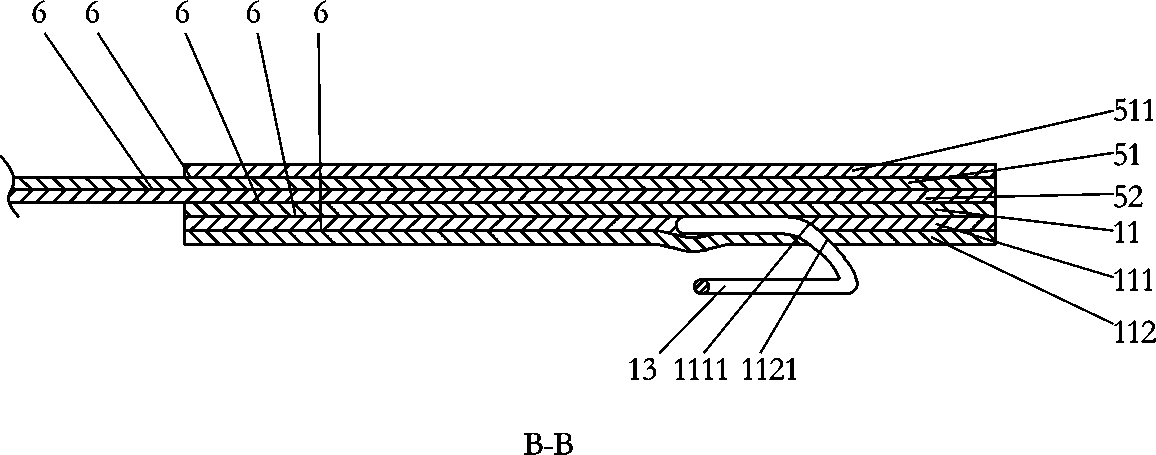

[0046] Such as Figure 1-4 As shown, the integrated structure of the side and back straps for bras in this embodiment includes a hook buckle 1, two side ratios 2, two rear ratios 3 and two back straps 4, two side ratios 2, The two back ratios 3 correspond to the two back straps 4 one by one; the side ratio 2 and the rear ratio 3 are integrally connected with the corresponding back straps 4 to form a whole-piece structure 5, and the whole-piece structure 5 is composed of outer fabric 51 and The inner layer fabric 52 is formed, the outer layer fabric 51 is overlapped with the inner layer fabric 52 and has the same shape and size, and the edge of the outer layer fabric 51 is attached to the edge of the inner layer fabric 52 through the rubber strip 6; the hook button 1 includes a first gasket 11. The second gasket 12, a row of crotch hooks 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com