Sorting equipment

A technology of equipment and conveying unit, which is applied in the field of sorting equipment, can solve problems such as difficult modularization, large floor space, and complexity, and achieve mass production and assembly, reduce floor space, and realize the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

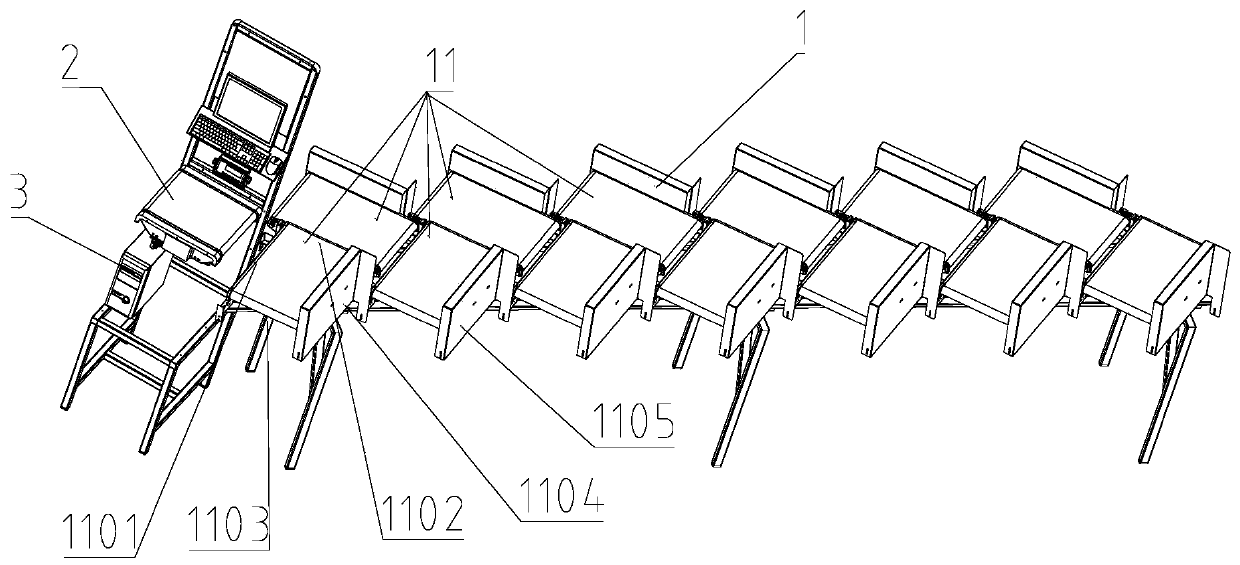

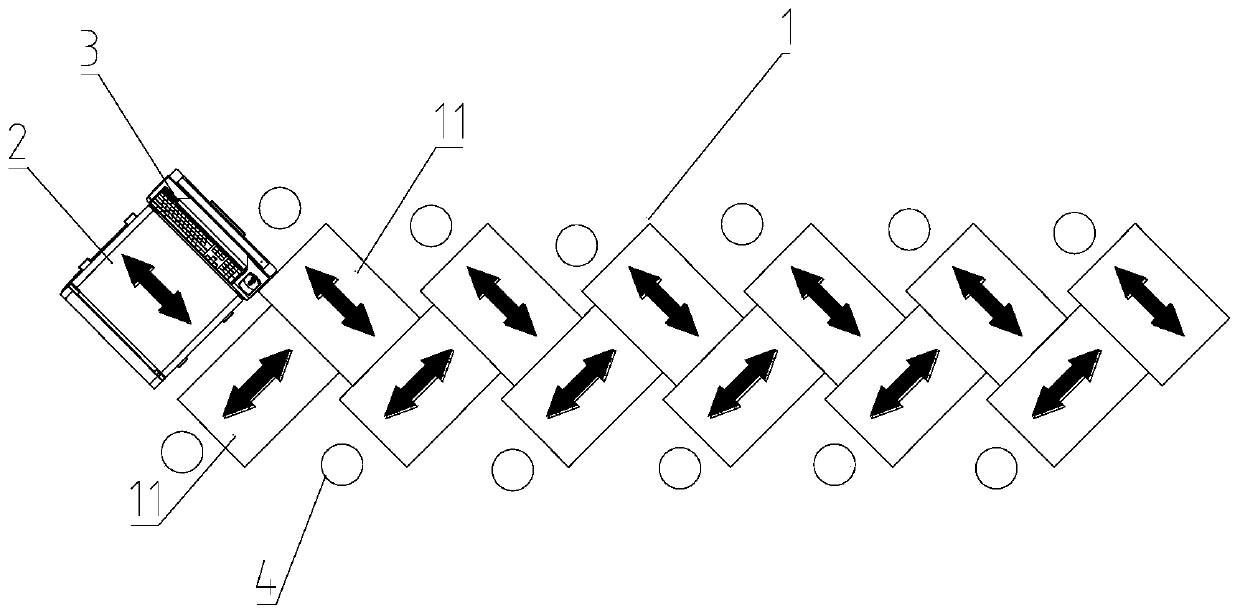

[0028] Below in conjunction with each accompanying drawing, the present invention is described in detail.

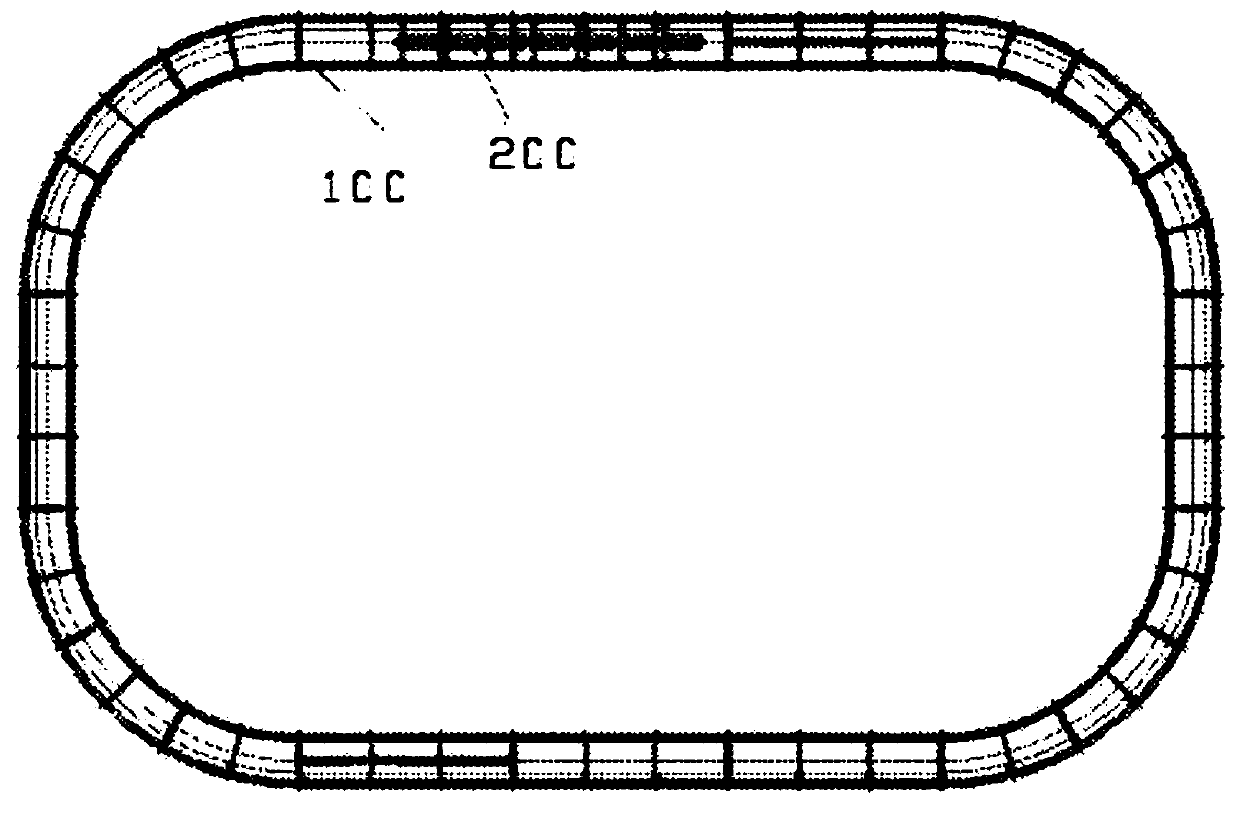

[0029] Such as figure 2 and 3 As shown, a kind of sorting equipment, comprises bag-up module 2, bag collection module 4, delivery module 1, identification module (not shown in the figure) and controller 3, and identification module is used for identifying the information of goods to be sorted and Determine the properties of the goods to be sorted, and feed back the above information to the controller 3; the package module 2 is used to transport the goods to be sorted after the identification module to the conveying module 1; the conveying module 1 is used to transfer the The goods to be sorted by the upper package module 2 are transported to the corresponding package collection module 4; the controller 3 is used to control the various modules of the sorting equipment to work as a whole; the package collection module 4 is used to collect the sorted goods; the delivery m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com