Oil pressure type automatic extension grinding rod for grinding inner diameter and using method of oil pressure type automatic extension grinding rod

A grinding oil and grinding rod technology, which is applied to grinding tools, grinding machines, grinding machine parts, etc., can solve the problems of time-consuming and labor-intensive replacement, complex structure of grinding equipment, high cost, etc., and achieve fast installation and replacement, simple structure, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

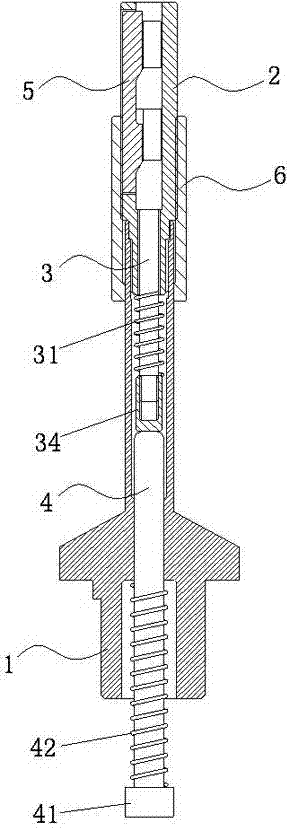

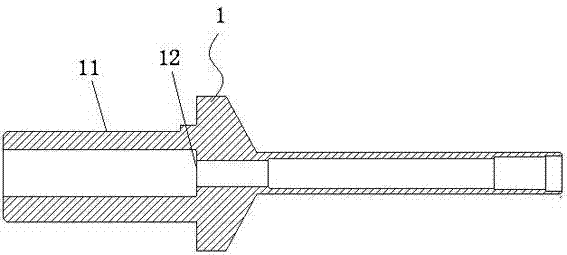

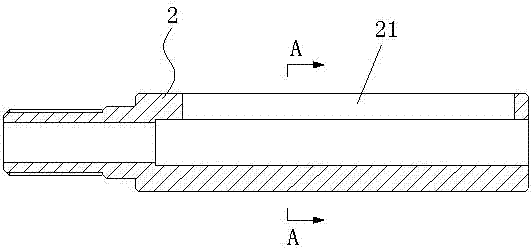

[0020] Embodiment one: if Figure 1~6 As shown in the figure, an oil-pressure automatic externally stretched grinding rod for inner diameter grinding includes a rotating shaft 1 whose rear end is sheathed on the rotary machine table and rotates with it. The front end of the rotating shaft 1 is threadedly connected with a shaft sleeve 2 The shaft 1 and the shaft sleeve 2 are axially provided with a through hole with the same center line, and the through hole is installed with a mandrel 3 and a push rod 4 sequentially from front to back, and the front side wall of the shaft sleeve 2 is There are three sand bar holes 21 communicating with the through holes. Two cylindrical protrusions 32 are arranged on the spacer ring on the front side wall of the mandrel 3, and three inclined surfaces 33 are evenly distributed on the front ends of the protrusions 32. Protrusion 32 is positioned at the scope of sand bar hole 21, and sand bar 5 is placed in described sand bar hole 21, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com