vertical axis turbine

A water turbine and vertical shaft technology, applied in hydroelectric power generation, mechanical equipment, engine components, etc., can solve the problems of increasing flow resistance, reducing the hydrodynamic characteristics of turbine blades, and poor performance under variable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments illustrate the arc-shaped two-piece shielding cover of the present invention in detail with reference to the accompanying drawings.

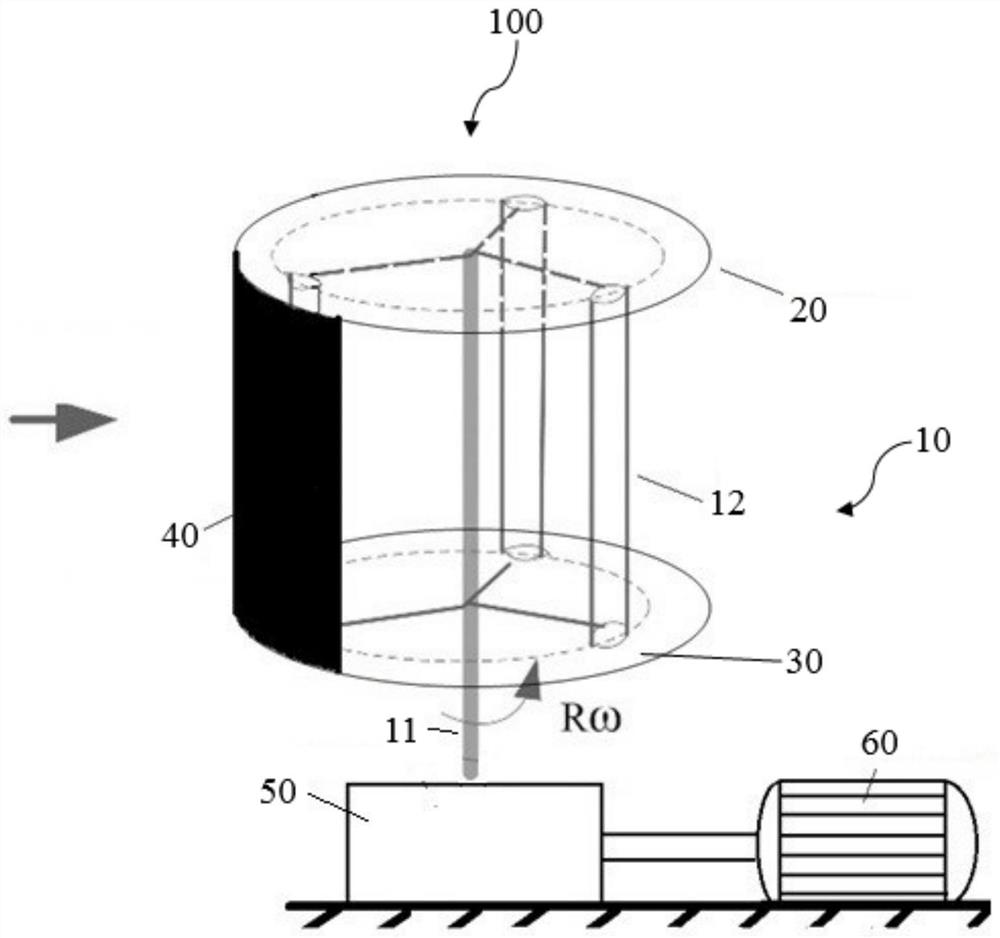

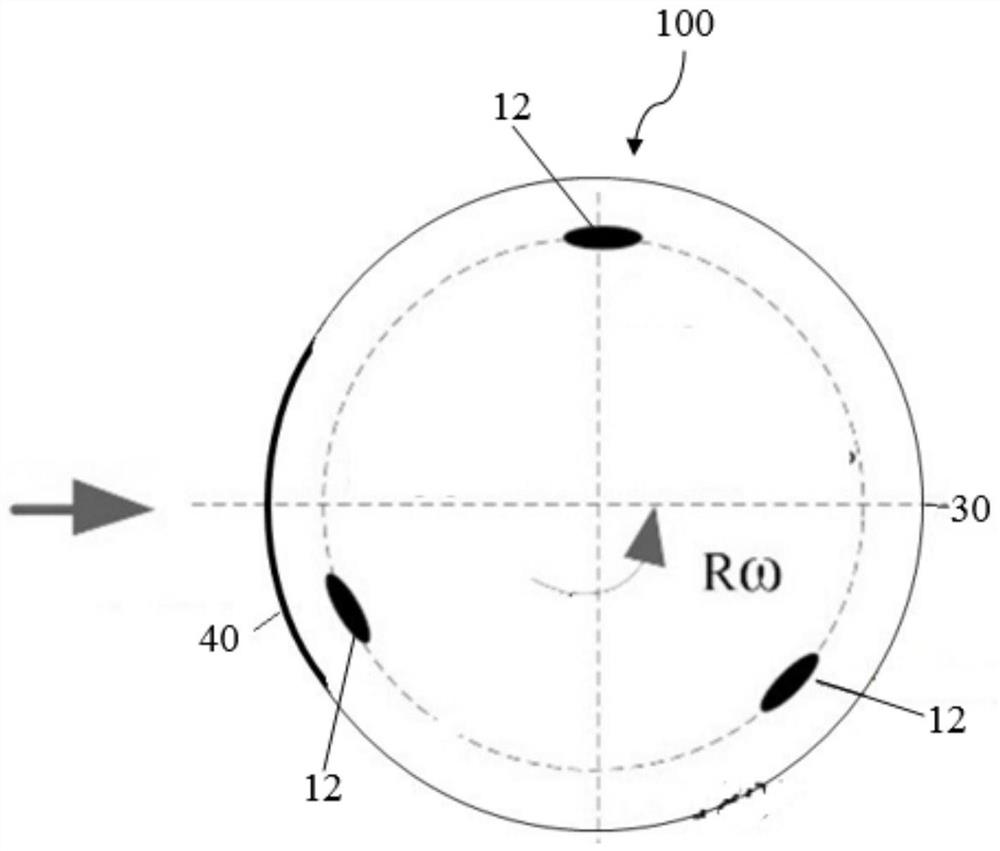

[0016] figure 1 It is the elevation view of the vertical axis water turbine in the embodiment of the present invention; figure 2 It is the elevation view of the vertical axis water turbine in the embodiment of the present invention.

[0017] Such as figure 1 , 2 As shown, the vertical axis water turbine 100 includes a rotor 10 , an upper cover 20 , a lower cover 30 , an arc baffle 40 , a gearbox 50 and a generator 60 .

[0018] The rotor 10 is a lift rotor with three blades and has a shaft 11 and three blades 12 . The three blades 12 are equiangularly distributed and fixedly arranged on the side of the rotating shaft 11, and the angle between any two blades 12 among the three blades 12 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com