Ink cartridge for digital jet printing

An ink cartridge and digital technology, applied in the field of ink cartridges for digital inkjet printing, can solve the problems of energy consumption, waste of resources, and only ink cartridges can be replaced, and achieve the effects of preventing secondary blockage, preventing nozzle blockage, and avoiding poor ink supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

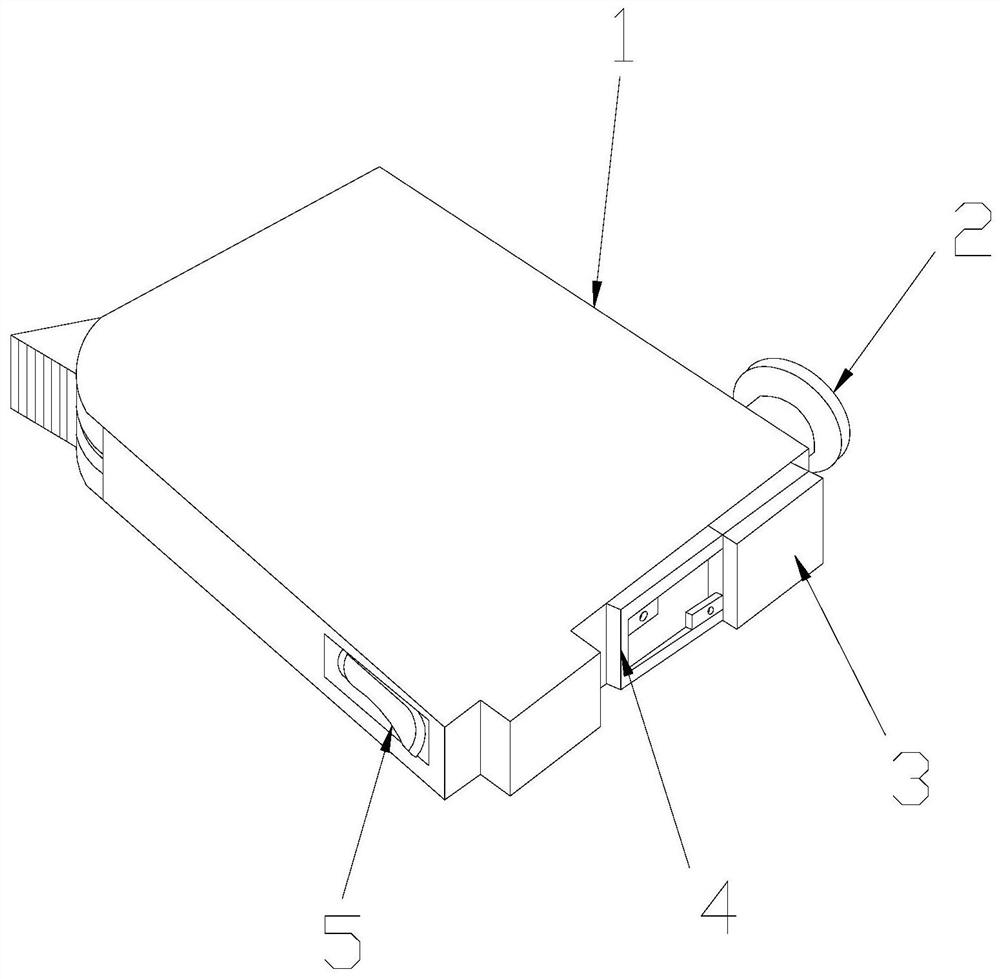

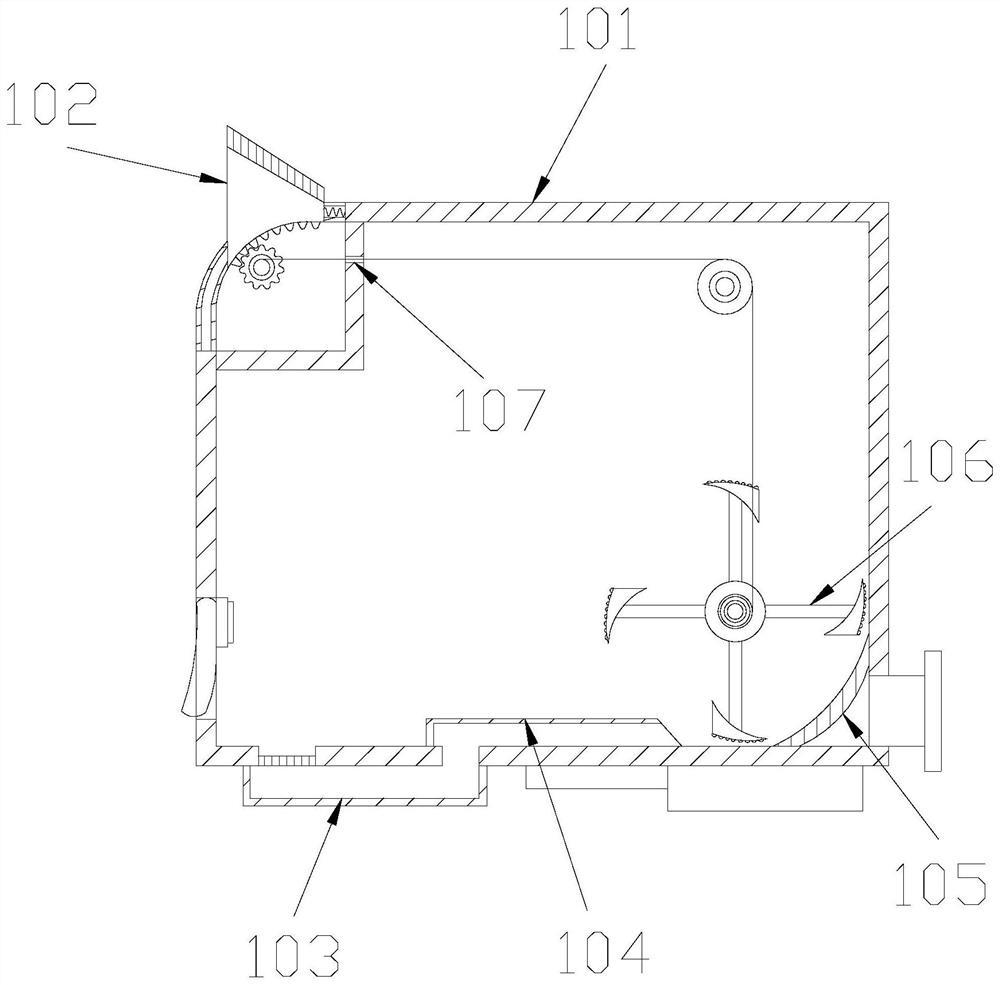

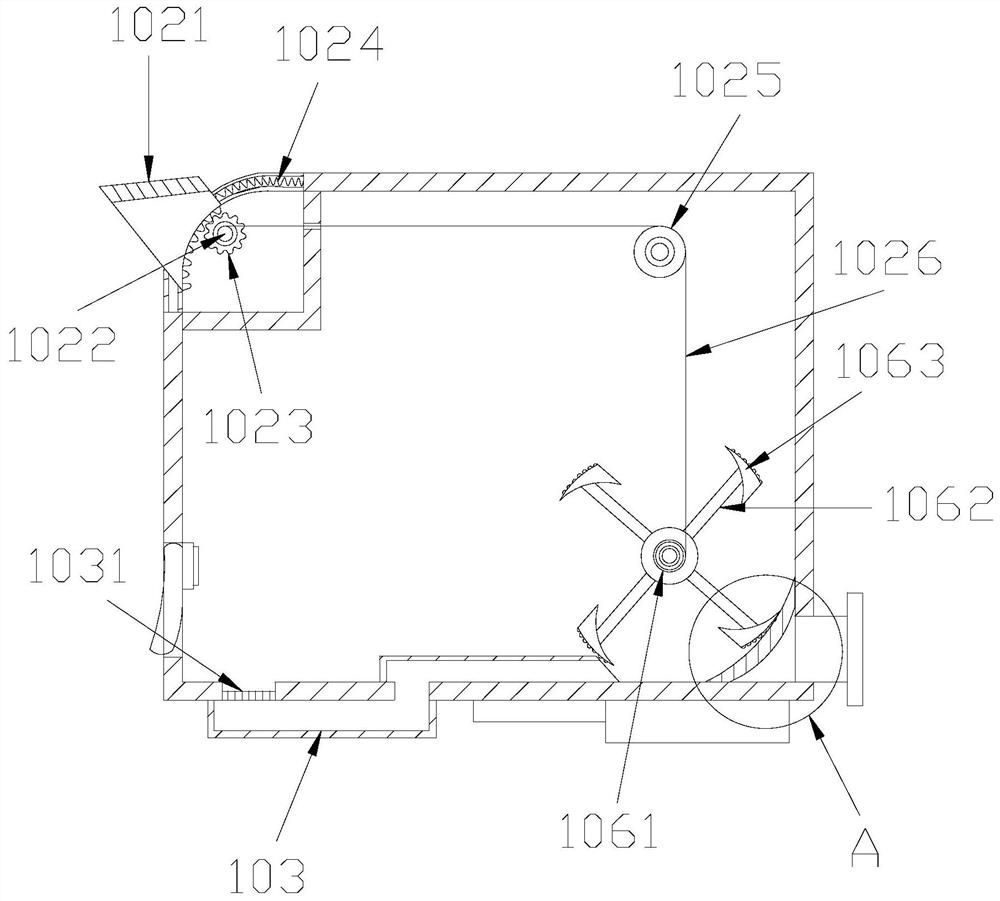

[0030] see Figure 1-Figure 5 , the present invention provides an ink cartridge for digital jet printing, the structure of which includes an ink cartridge 1, a nozzle 2, a nozzle chip 3, a fastening frame 4, and an ink inlet valve 5, and the middle position of the bottom end of the ink cartridge 1 is provided with a fastening frame 4. The ink cartridge 1 and the buckle frame 4 are fixedly connected, the nozzle wafer 3 is arranged on the right side of the buckle frame 4, the ink cartridge 1 and the nozzle wafer 3 are flexibly connected, and the right end of the ink cartridge 1 is lowered The nozzle 2 is provided, the ink cartridge 1 and the nozzle 2 are an integrated structure, the left end of the ink cartridge 1 is provided with an ink inlet valve 5, the ink cartridge 1 and the ink inlet valve 5 adopt a clearance fit, and the ink cartridge 1 is composed of a housing 101, a sliding mechanism 102, a recovery box 103, a guide tube 104, a filter screen 105, a cleaning mechanism 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com