Electric heating device and fault detection method and control device thereof

An electric heating device and fault detection technology, applied in the direction of electric heating devices, measuring devices, electrical components, etc., can solve the problems of shortened life of heating tubes, fire, and inability to effectively notify components, etc., to reduce inconvenience, avoid losses, Ease of timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

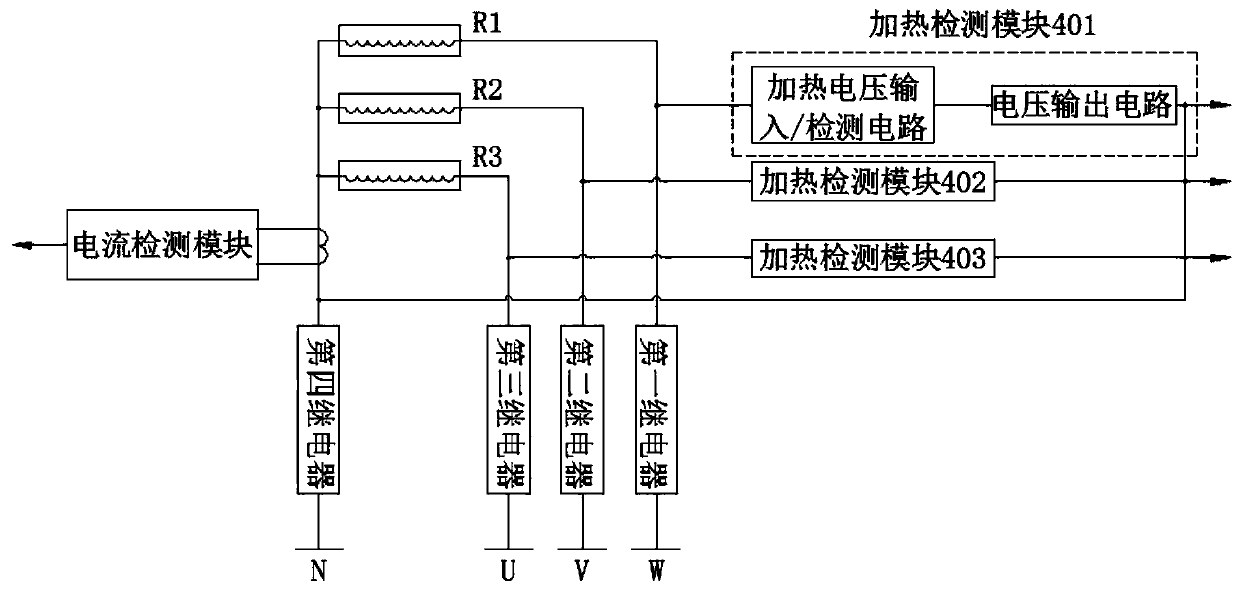

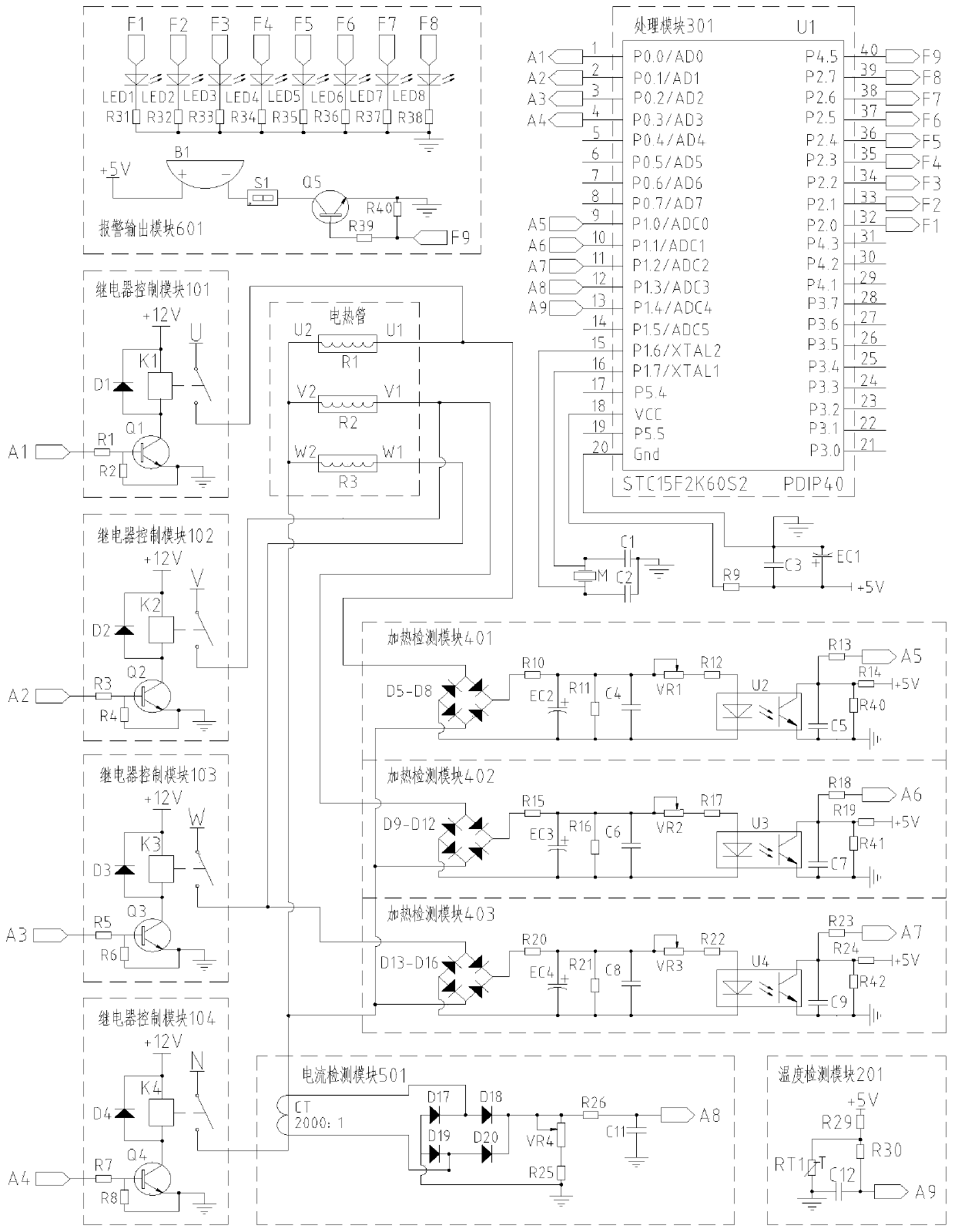

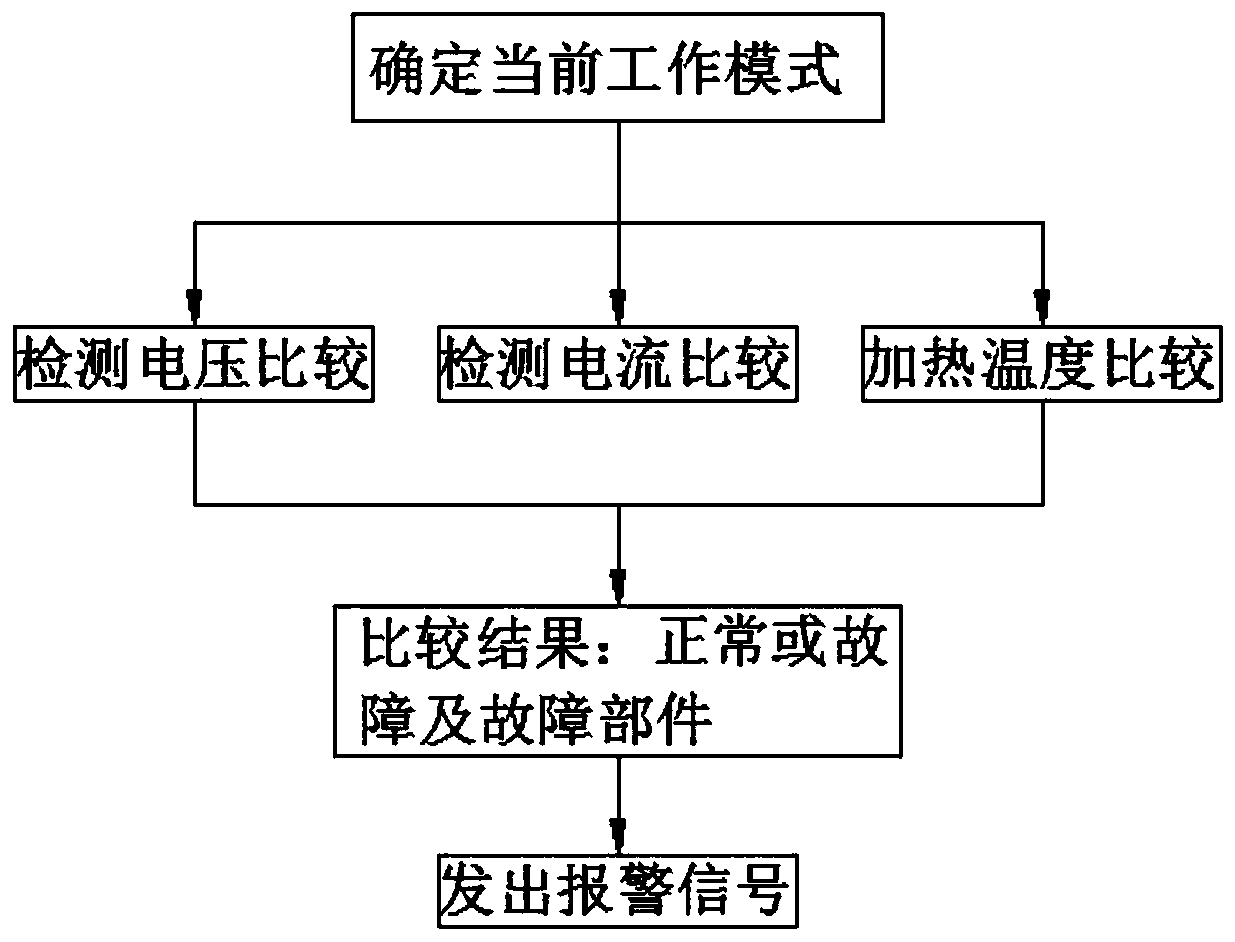

[0039] Such as figure 1 and figure 2 As shown, an electric heating device includes:

[0040] The electric heating circuit includes three heating tubes. One end of the three heating tubes is connected to the common terminal in a star shape, and the other end is respectively connected to U, V, and W of the AC power supply through the first relay, the second relay, and the third relay. The input terminal is electrically connected, and the common terminal is electrically connected to the N terminal through the fourth relay.

[0041] The current detection module includes a current detection element coupled on the line between the common terminal and the N terminal. The current detection module converts the induced current detected by the current detection module into a current that can be recognized by the controller after rectification and voltage regulation filtering DC signal output.

[0042] Three sets of heating detection modules for fault detection of the heating tube and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com