Integrated circuit chip testing and sorting machine reclaiming device and control method

A technology for chip testing and integrated circuits, which is applied in the field of retrieving devices for integrated circuit chip testing and sorting machines, and can solve problems such as unstable retrieving, material falling, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

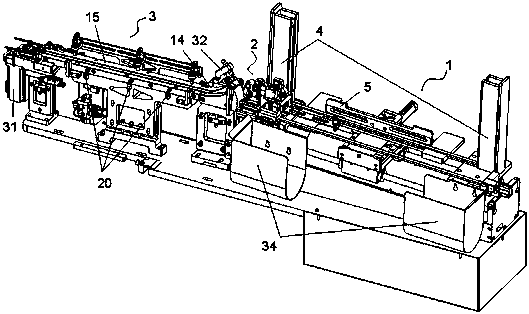

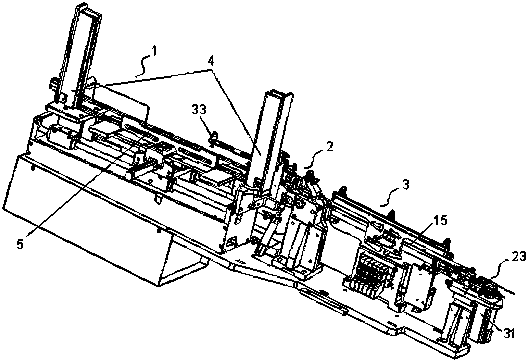

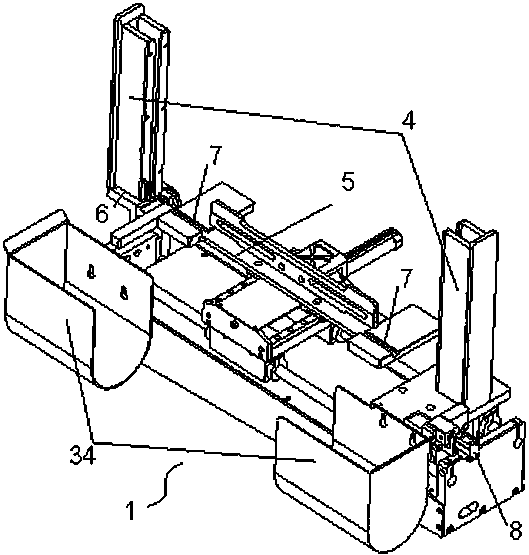

[0029] The reclaiming device of the integrated circuit chip test sorter includes a material pipe conveying device 1, a material pipe tilting device 2 and a material conveying device 3 arranged in sequence along the moving direction of the material. The upper surface of the initial section of the material conveying device is formed by an arc The transition is upwardly inclined, and the material pipe inclination device can be rotated to be tangent to the initial section of the material conveying device. the length of a material;

[0030] The semi-conductor material after preliminary molding is placed in the material tube, and the material tube storing the material is first conveyed to the material tube tilting device through the material tube conveying device, and then rotated and tilted by the tilting device, so that the material slides smoothly under the action of gravity to In the material conveying device, it is conveyed to the next station through the material conveying dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com