High-position automatic docking platform for large motorized radar

An automatic docking and platform technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of the docking platform failing to meet the precision requirements, long docking time, poor stability and safety, etc., to reduce the occupied space, improve the The effect of docking accuracy and increasing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to detail the technical content, structural features, achieved objects and effects of the present invention, the following will be described in detail with reference to the accompanying drawings.

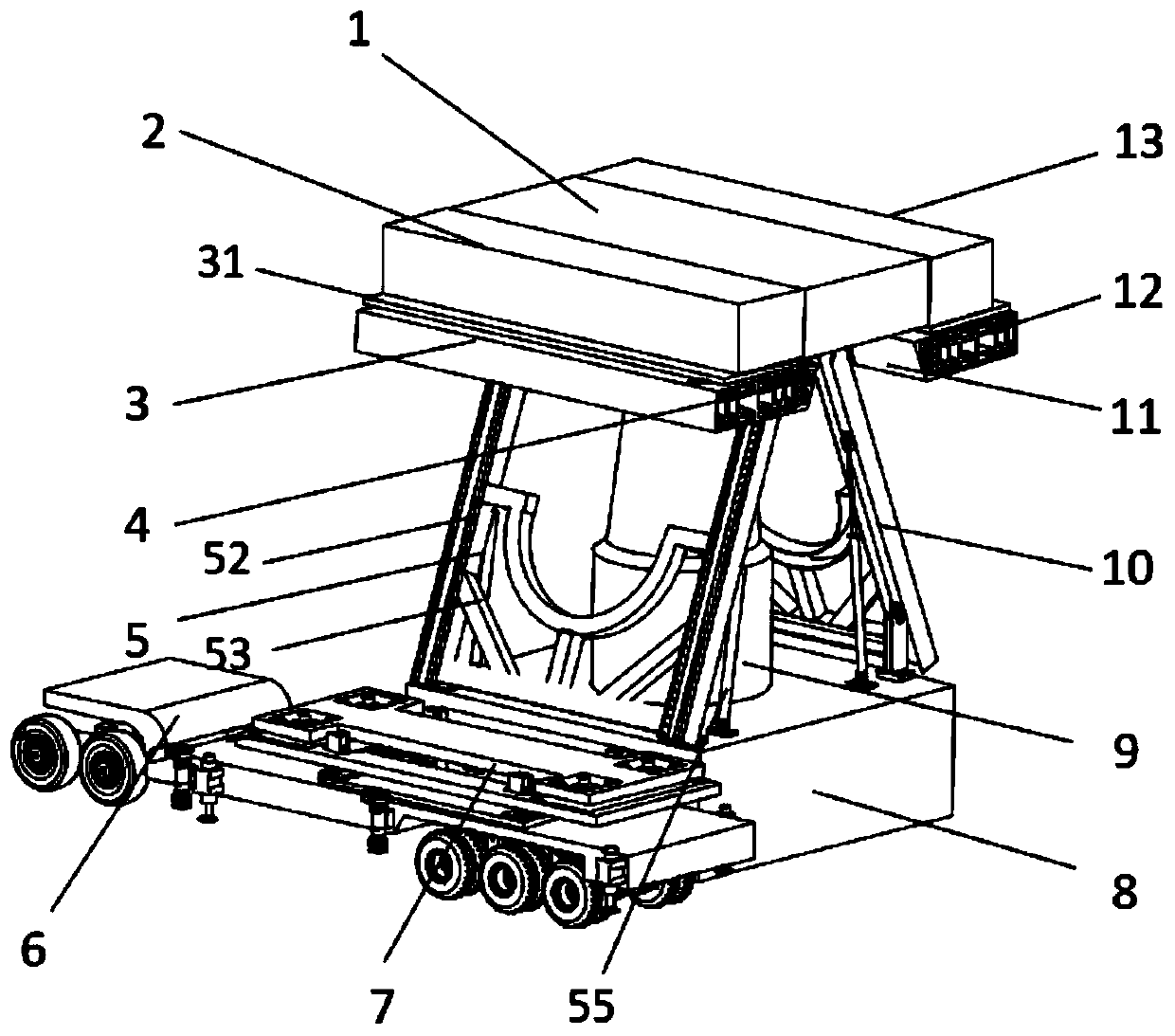

[0025] A large-scale mobile radar high-level automatic docking platform, such as figure 1 As shown, it includes a radar antenna center block 1, a first docking antenna 2, a first docking mechanism 3, a first lifting vehicle 4, a first lifting mechanism 5, a transport vehicle 6, a six-degree-of-freedom attitude adjustment platform 7, a basic platform 8, The support column 9 , the second lifting mechanism 10 , the second lifting vehicle 11 , the second docking mechanism 12 and the second docking antenna 13 .

[0026] The foundation platform 8 is located on the ground, the support column 9 is fixed on the center of the upper surface of the foundation platform 8, the first end of the support column 9 is connected with the radar antenna center block 1, and the four vertex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap