LED display screen assembled with static display frame

A technology of LED display screen and display frame, which is applied in the field of LED display screen assembled with static display frame, can solve the problems of display screen damage, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

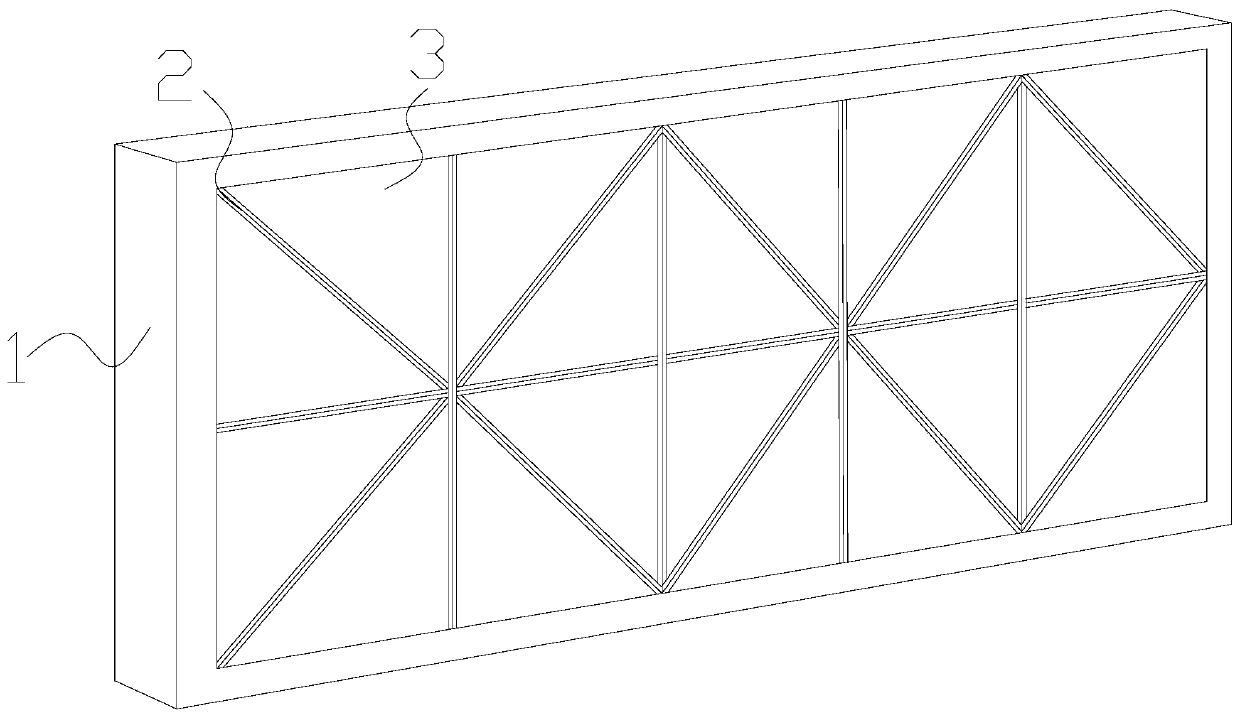

[0029] The invention provides an LED display screen assembled with a static display frame, the structure of which includes a fixed protective frame 1 , a sliding joint 2 , and a triangular display screen 3 .

[0030] The sliding connecting road 2 is welded on the outer surface of the triangular display screen 3, the sliding connecting road 2 is loosely matched with the fixed protective frame 1 and connected flexibly, and the triangular display screen 3 is connected with the fixed protective frame 1 through the sliding connecting road 2 .

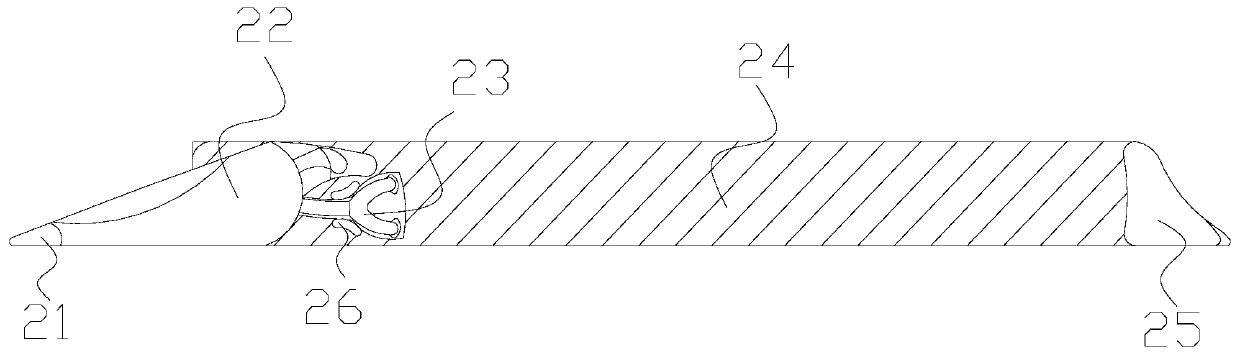

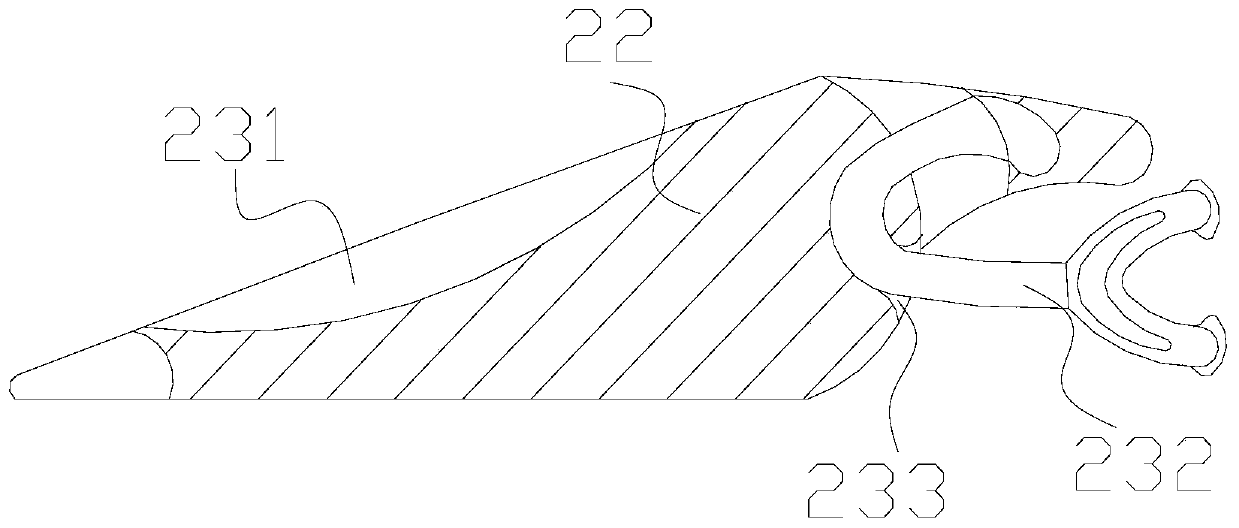

[0031] The sliding connection road 2 includes a push angle 21, a wind and sand pushing shovel body 22, an elastic clip 23, a main slide bar 24, an inclined boost angle 25, and a rebound clip angle 26. 22, the elastic clamp 23 and the wind-sand pushing shovel body 22 are an integrated structure, the rebound clip 26 is located at the upper and lower ends of the elastic clamp 23, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap