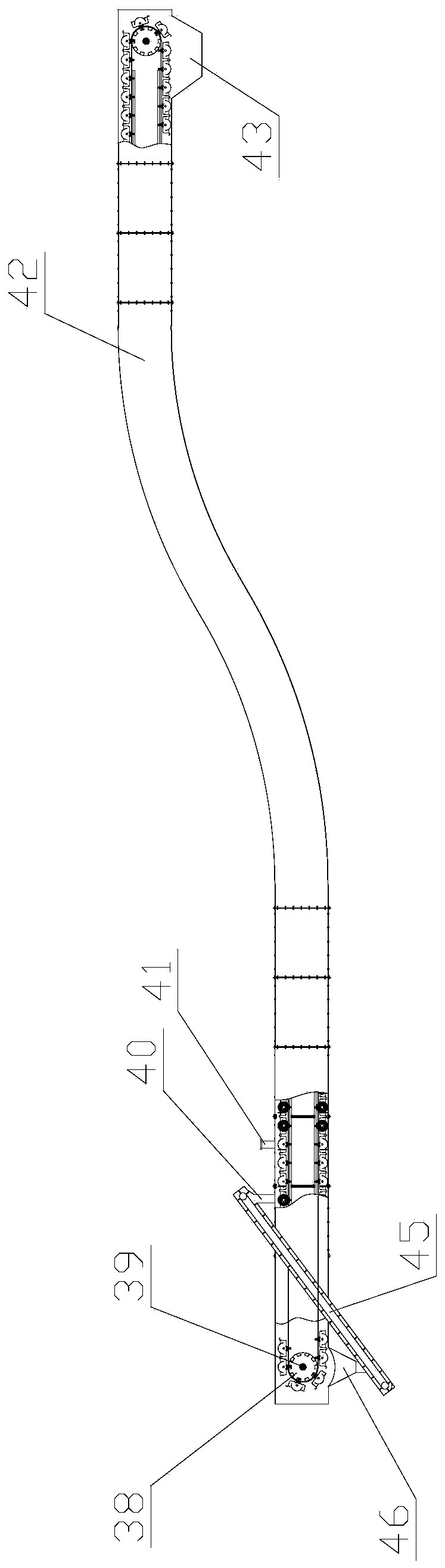

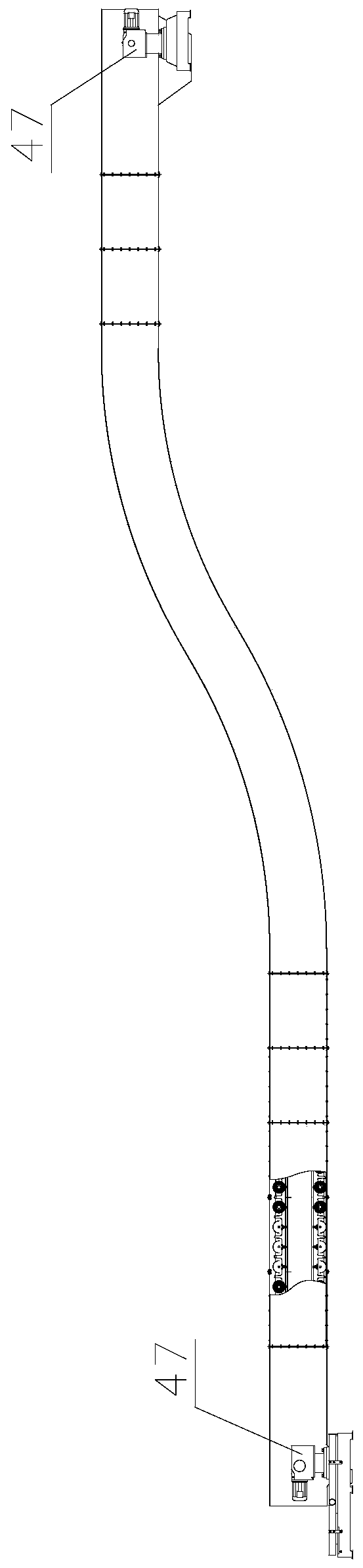

Toothed cable bucket conveyor

A conveyor and bucket type technology, applied in the field of tooth rope bucket conveyor, can solve the problems of increased reaction force and vibration force of steel wire rope, large hopper wear, loose bolts, etc., to save material costs and installation costs, smooth operation and Stable and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

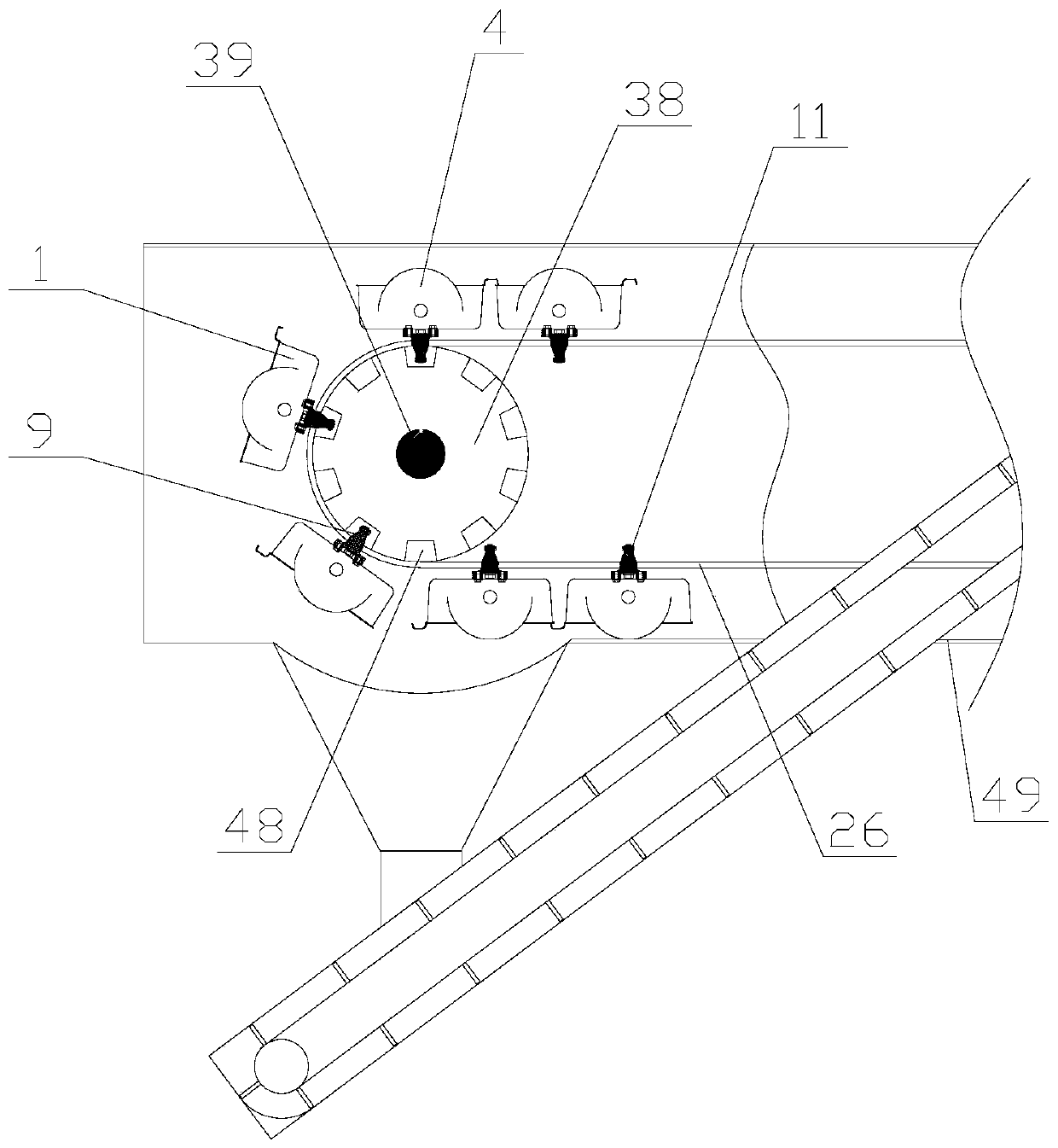

[0058] Such as Figure 18 , Figure 19 , Figure 20 As shown, another specific embodiment of the screw connection structure of the toothed cable tooth block assembly 9: there are three second threaded holes 31 arranged in a straight line on the tooth block 19, and there are three second threaded holes 31 on the corresponding positions on the pressure plate 18. Three third through holes 30 through which the bolts 29 pass. Four fixing lugs 27 are arranged on the pressing plate 18, and four are rectangularly arranged on the four fixing lugs 27 and are provided with the third threaded hole 31 that four third bolts are screwed together. The position corresponding to 28 has four fourth through holes 15 for the passage of four third bolts.

[0059] The tooth block 19 is a tooth block made of cast iron material, and the pressing plate 18 is a pressing plate made of aluminum alloy material. The material of the tooth block 19 and the pressing plate 18 is soft and hard, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com