Product combination and scheduling optimization method under whole batch processing mode

A product combination and optimization method technology, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of decomposition without overall consideration and local optimization, so as to increase effective output, improve resource utilization, and expand application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0037] The calculation example of the present embodiment is shown in Table 1:

[0038] Table 1 Calculation example description

[0039]

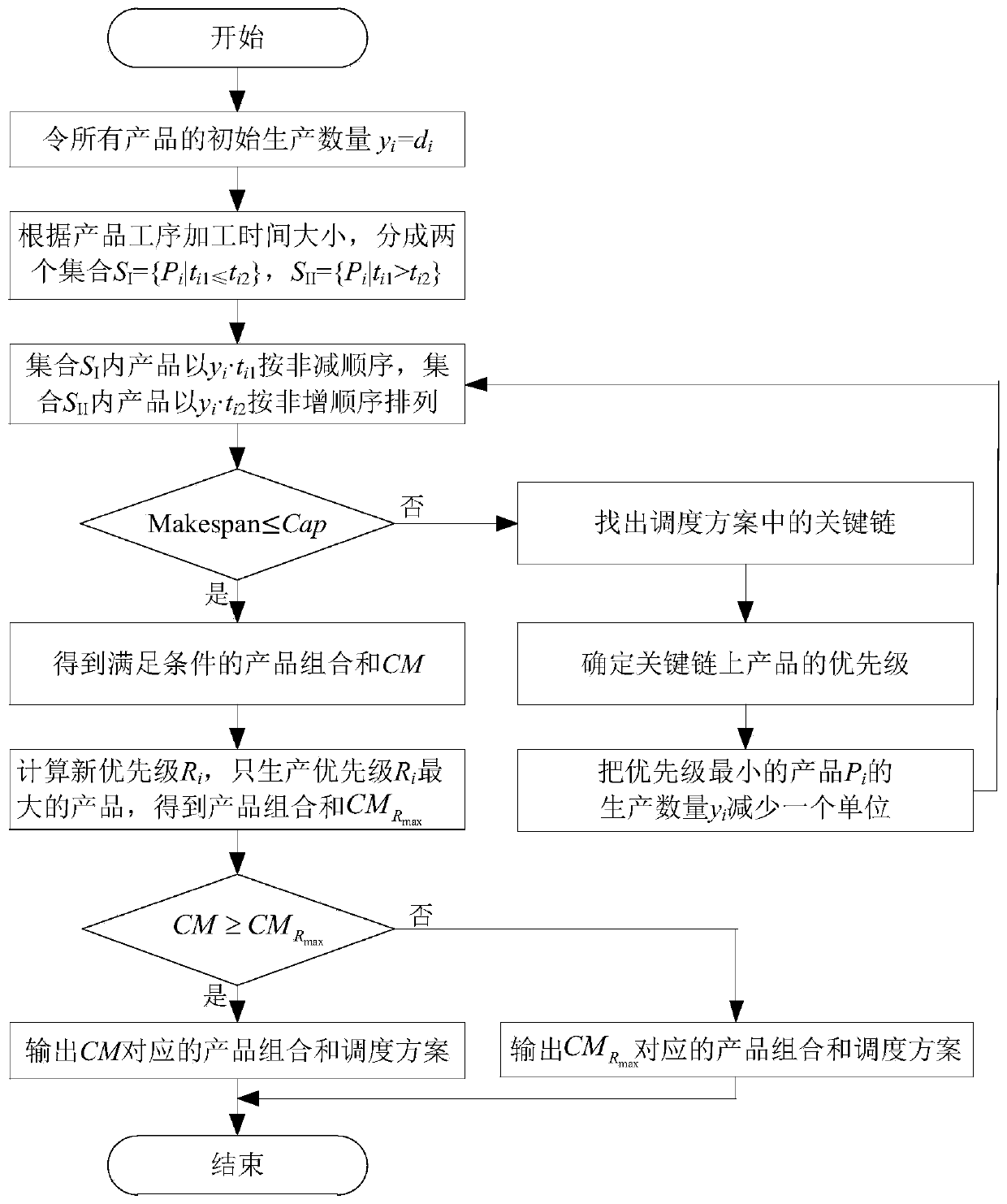

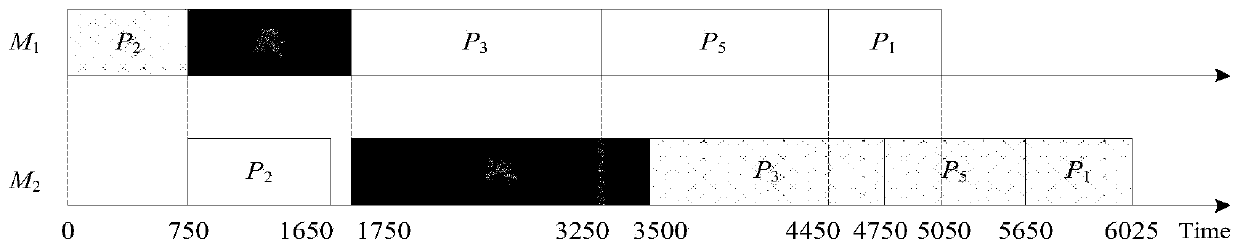

[0040] For the above calculation example, the product combination and scheduling optimization method under the whole batch processing mode in the present invention will be used, and the specific method steps are:

[0041] Step 1: According to the market demand d of each product i i Determine the initial production quantity y of each product i i ,y i = d i , i=1,2,...,n; y 1 =15,y 2 =30,y 3 =50,y 4 =50,y 5 =30.

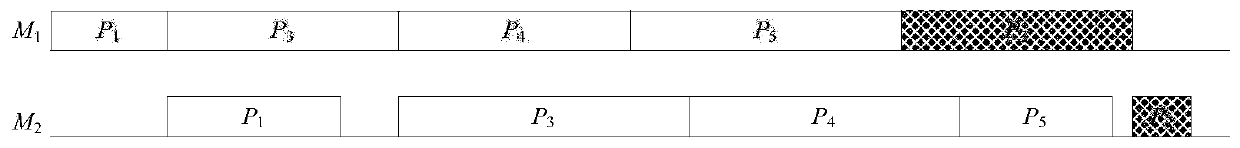

[0042] Step 2: According to each product in machine M 1 The individual processing time on and on the machine M 2 A single processing time on , divides the product into two subsets: S Ι ={P i |t i1 ≤...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com