Metal strip bending machine and bending process using same

A metal strip and bending machine technology, applied in the field of copper plate and copper strip detection, can solve the problems of increased tool wear, the bending tool violently hitting the bottom of the workpiece groove, affecting the service life of the bending tool, etc., to achieve smooth bending processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

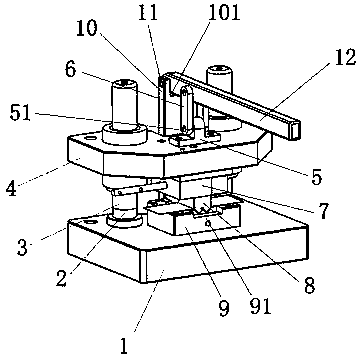

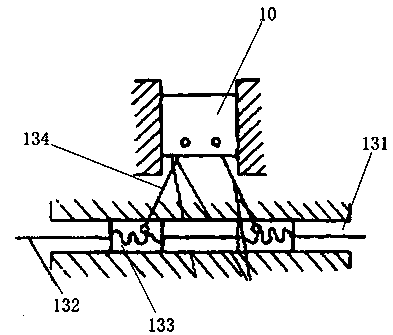

[0019] Embodiments of the metal strip bending machine in the present invention will be further described with reference to the accompanying drawings.

[0020] As shown in the drawings, this embodiment is a metal strip bending machine, which includes a base 1, and two guide posts 2 are supported on the top surface of the base, and damping is set on the guide posts. Sleeve 3, the damping sleeve is fixed on the guide post by means of threaded connection, a mounting plate 4 is set on the damping sleeve, the damping sleeve is clamped between the mounting plate and the guide post, the core of the damping sleeve is a spring, An extension block is arranged on the side of the spring, and the extension block extends outside the damping sleeve and is connected with the mounting plate. Specifically, when the mounting plate is pressed up or down under force, the extension block can be driven up or down, Therefore, the spring is pressed by the extension block, so that the spring accumulates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com