U-bolt bending equipment

An equipment and bolt technology, which is applied in the field of high-strength special-shaped U-bolt bending equipment, can solve the problems of dimension guarantee, difficulty in parallelism, expensive equipment, affecting accuracy, etc., and achieve stable bending process and good product consistency. , to ensure the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

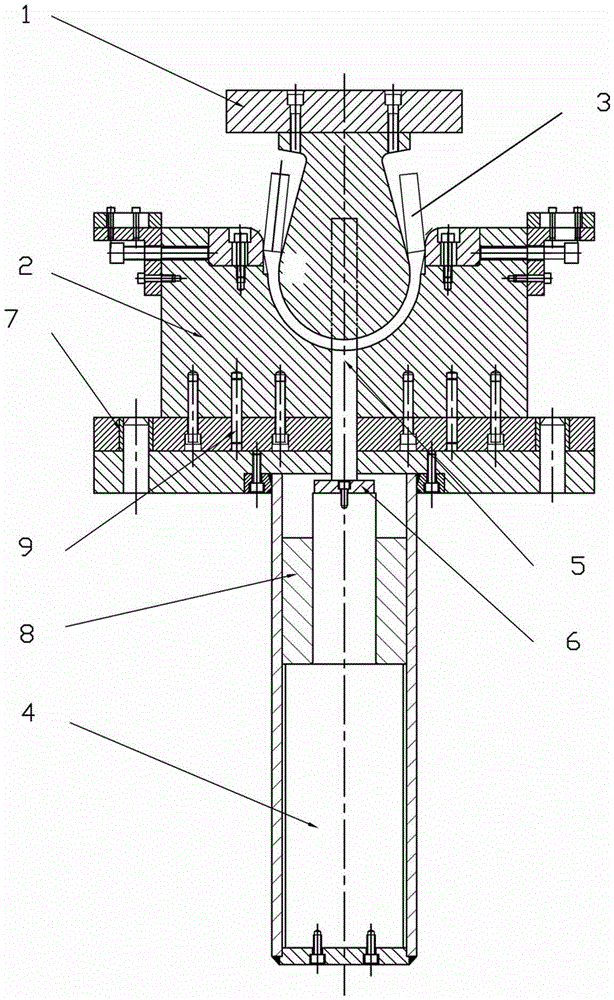

[0016] Such as figure 1 As shown, the U-bolt bending equipment of the present invention includes a bending mold and a press, and the press adopts a hydraulic press of more than 1000t, wherein the bending mold includes a punch and a die 2, and the die 2 is fixed on On the static mold base 7, the punch is arranged on the movable mold base 1. The movable mold base 1 is driven by a press. It also includes a support cavity, which runs through the entire movable mold base 7 and the die 2 arranged thereon, and reaches the blank 3 directly. A push rod 5 is arranged in the support cavity, and the push rod 5 is connected with a nitrogen spring device.

[0017] A plurality of positioning pins 9 are arranged on the bottom of the die 2 and the upper part of the static die base 7, so that the die 2 and the static die base are positioned and tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com