Heat insulation cushion and making method thereof

A cushion and cushion body technology, which is applied in the field of heat insulation cushion and heat insulation cushion manufacturing, can solve the problems of affecting the comfort, the temperature of the cushion rises, and is too soft, and achieves the effects of reducing production costs, good support, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

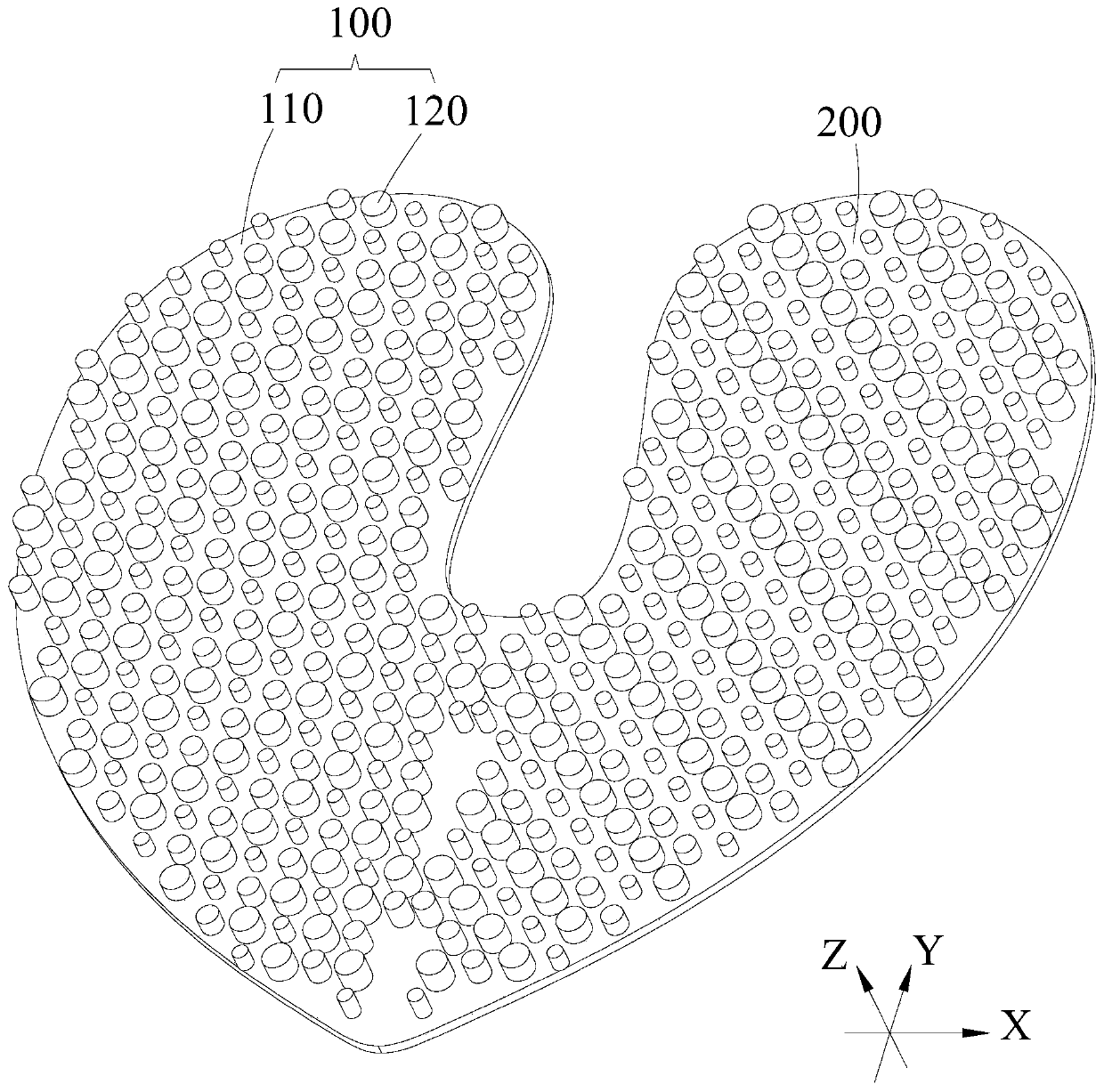

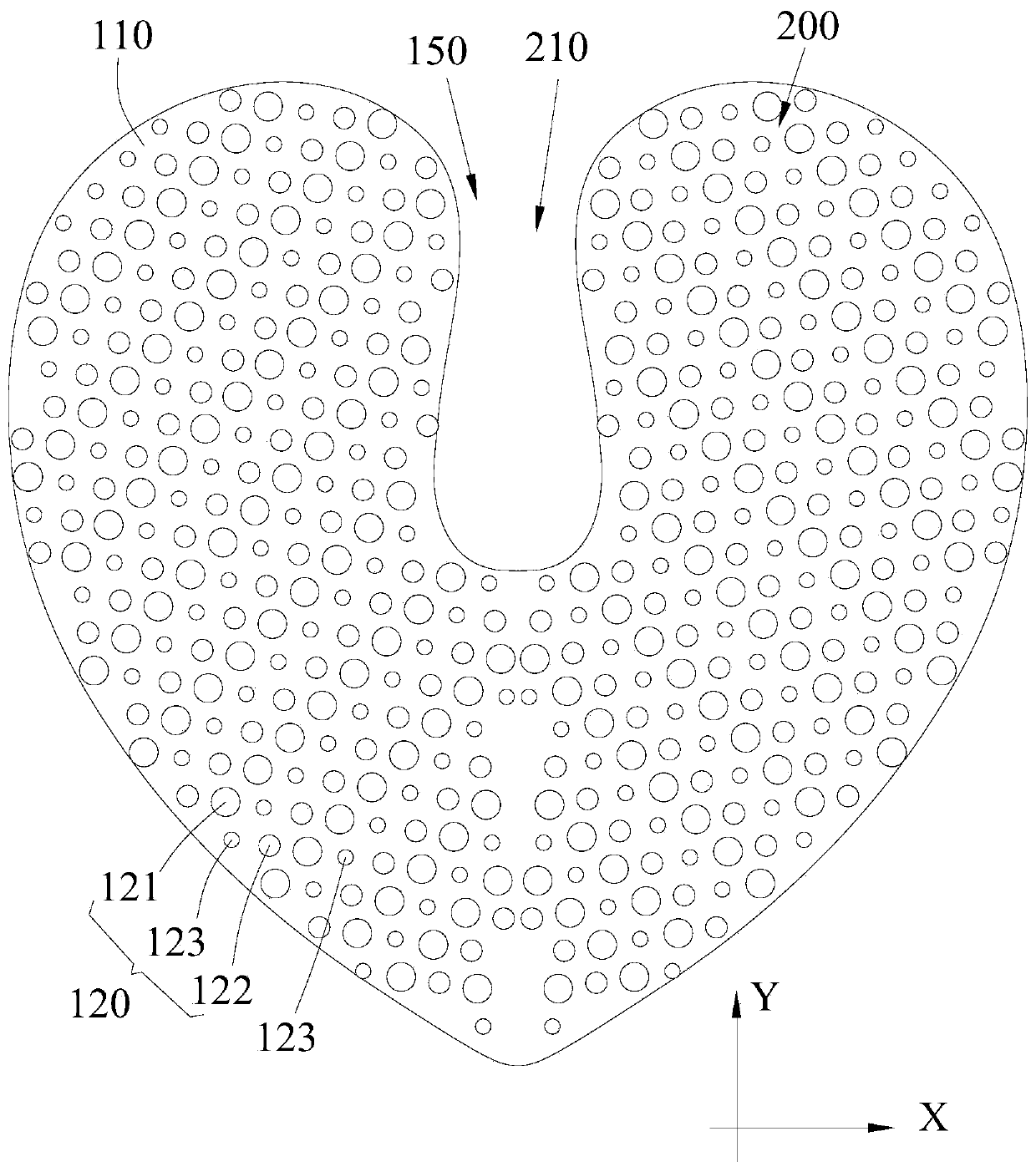

[0034] Please refer to Figure 1 to Figure 3 , This embodiment provides a heat-insulating cushion. When the human body naturally sits on the heat-insulating cushion, the front of the eyes is defined as the front, that is, the positive direction of the Y-axis.

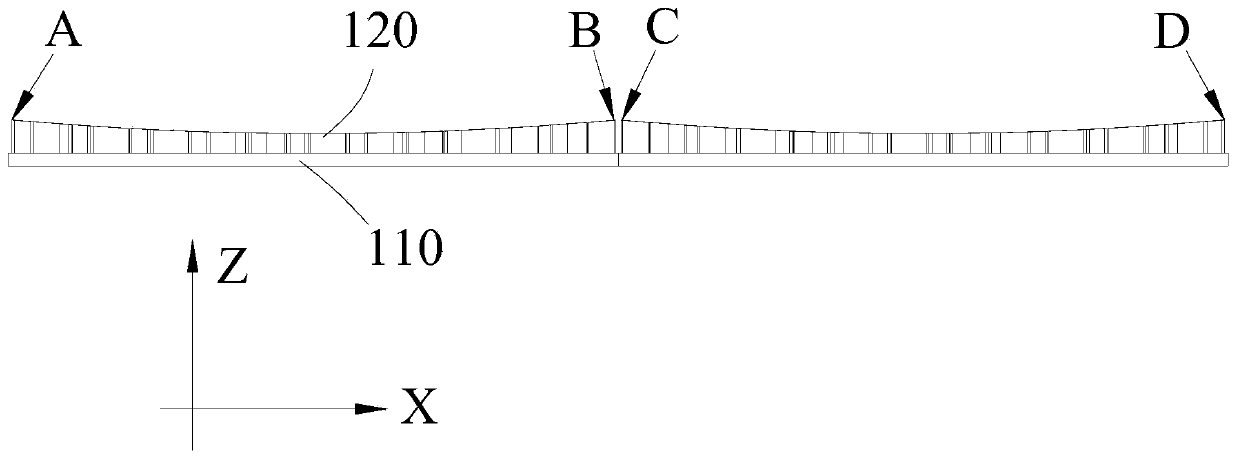

[0035] The heat insulation seat cushion includes a left cushion body 100 and a right cushion body 200 which are integrally arranged and symmetrically arranged left and right. The left cushion body 100 includes a left base plate 110 and a plurality of left convex posts 120 connected to the left base plate 110 and extending upward. 120 is provided with a left airtight cavity to accommodate air;

[0036] Each left protrusion 120 is made of elastic material, and any two left protrusions 120 are deformed under a downward force with a gap left.

[0037] Correspondingly, the right pad body 200 includes a right base plate and a plurality of right convex columns connected to the right base plate and extending upwards, and a rig...

Embodiment 2

[0057] This embodiment provides a method for manufacturing a heat-insulating cushion, which is used for producing a heat-insulating cushion. Please refer to Embodiment 1 for the specific structure of the heat-insulating cushion.

[0058] Please refer to Figure 4 , the manufacture method of heat insulation cushion comprises:

[0059] Step 1: pour the first liquid silicone into the first mold, and solidify to form the first module 130. The first module 130 includes a horizontally extending panel 131 and a hollow column 132 connected to the panel 131 and extending downward. The panel 131 There are a plurality of through holes that penetrate up and down, and the hollow column 132 has a blind hole with an upward opening, and the wall of the blind hole is connected with the wall of the through hole;

[0060] Step 2: Place the first mold part 130 on the second mold in reverse and there is a certain gap with the second mold, with the opening of the blind hole downward;

[0061] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com