An electrocatalytic total water splitting cozn-ldhs-zif@c composite structure material and its preparation method and application

A technology of electrocatalytic materials and composite structures, which is applied in the field of inorganic nanocatalytic materials, can solve problems such as low electrocatalytic efficiency, easy to be poisoned, and high price, and achieve improved electrocatalytic activity and stability, improved migration efficiency, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: In situ preparation of CoZn-LDHs on nickel foam

[0039] 0.5 mol / L Co(NO 3 ) 2 •6H 2 O aqueous solution was added to 0.5 mol / L Zn(NO 3 ) 2 •6H 2 O aqueous solution, stir rapidly until completely dissolved, then add urea, its molar concentration is 0.04 mol / L, stir while adding, continue to stir for 2 hours after completion, then add 3×3 cm 2 Place nickel foam horizontally at the bottom of the reactor, add the above solution, react at 100-120°C for 24 hours, cool to room temperature, wash with deionized water and absolute ethanol, and dry at 60°C for 12 hours to obtain a pink powder evenly covered in Nickel foam surface;

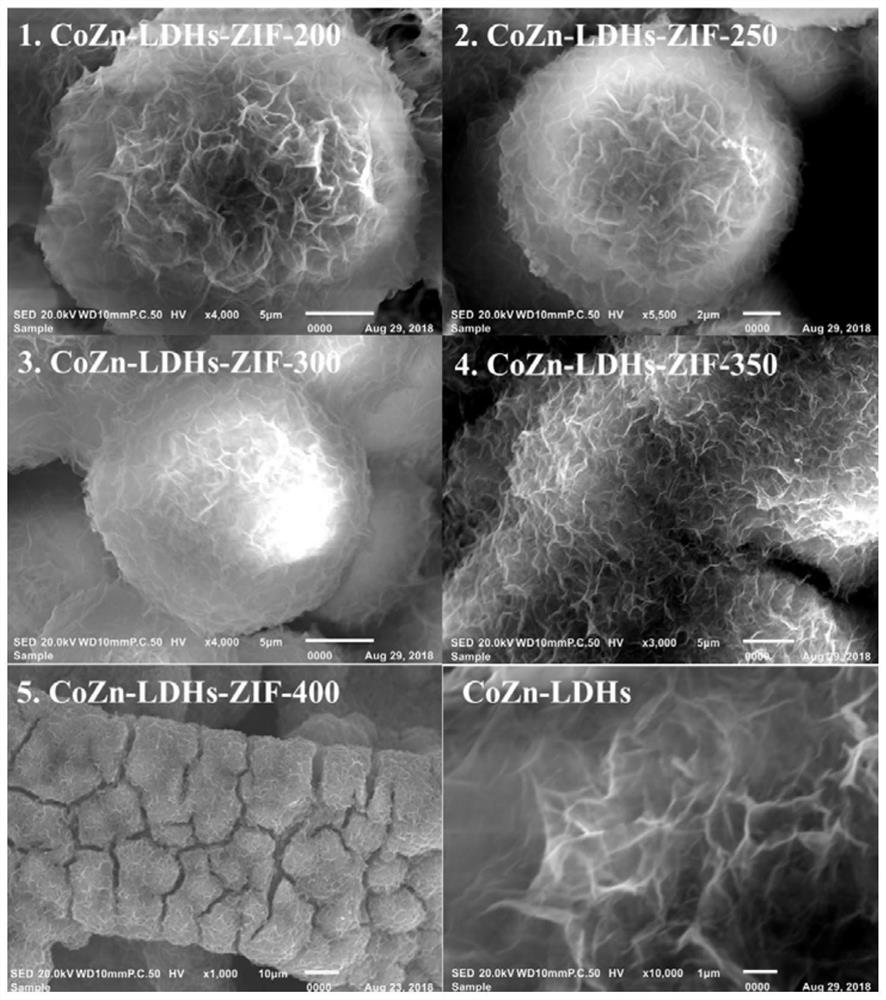

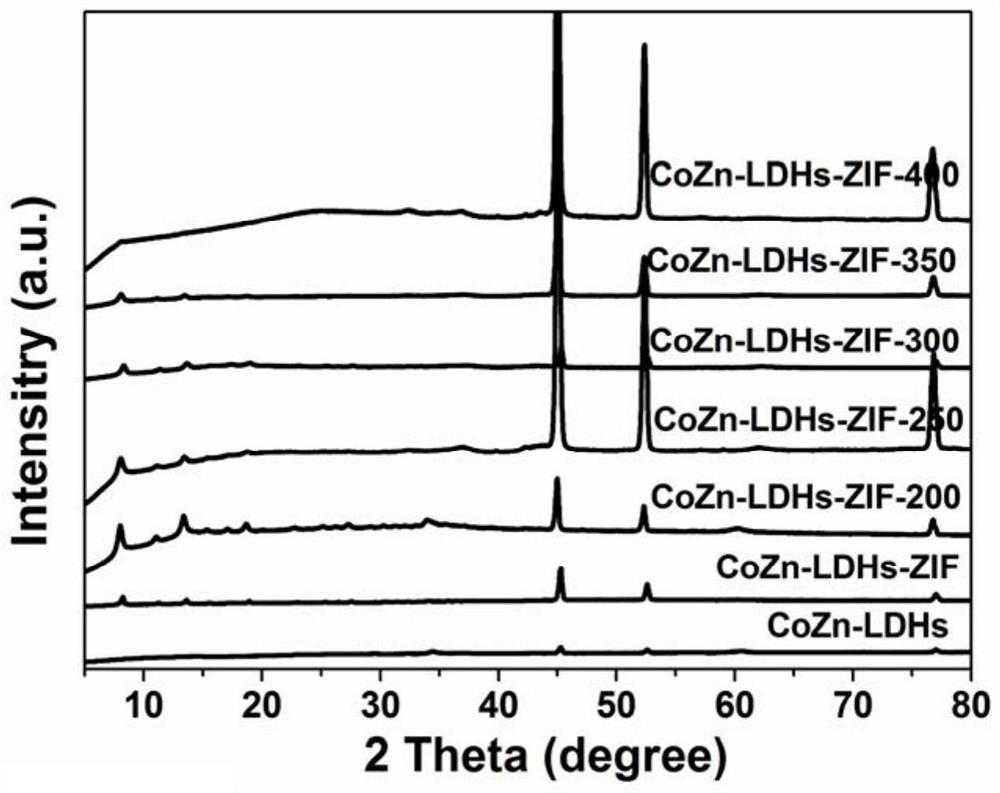

[0040] Micronano thin film material CoZn-LDHs on foamed nickel in embodiment 1, electron micrograph is as figure 1 -As shown in CoZn-LDHs, CoZn-LDHs has a multi-level spherical structure, the primary structure is a sheet, and the thickness is 10-20nm, and the secondary spherical structure is 10-15μm in size. figure 2 The X-ray diffr...

Embodiment 2

[0041] Embodiment 2: Preparation of CoZn-LDHs-ZIF

[0042] Taking step 1) synthesized CoZn-LDHs on the surface of nickel foam, the size is 1×1 cm 2 , placed in 50ml of methanol solution dissolved with 0.1g of dimethylimidazole, soaked for 48 hours, after the reaction, rinsed with demethanol and absolute ethanol in turn, and dried in vacuum at 60°C for 12h to obtain CoZn-LDHs surface loaded ZIF Precursors of particulate electrocatalytic materials.

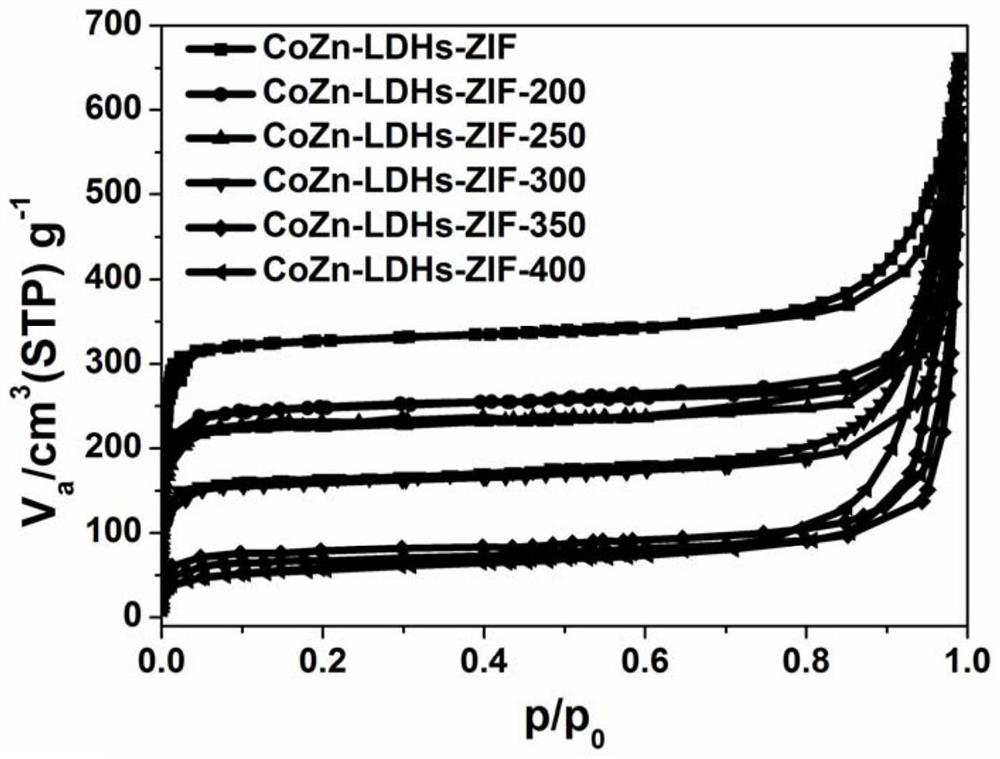

[0043] The particle size of the sample ZIF-67,8 obtained in Example 2 is 200-500 nm, and the shape is irregular nano-particles. figure 2 The X-ray diffraction pattern of this sample of CoZn-LDHs. image 3 It is the CoZn-LDHs-ZIF specific surface area test chart, from which the BET area of this sample is calculated to be 1125.1 m 2 / g. Figure 5 It is the HER and OER electrocatalytic performance test chart of the sample. Figure 6 It is the electrocatalytic water splitting test of this sample.

Embodiment 3

[0044] Example 3: Take the ZIF-loaded CoZn-LDHs sample in step 2), and place it in a tube furnace for calcination. The gas source used is high-purity argon, and the flow rate is 50 ml / min. The calcination temperature is 200 degrees centigrade, the heating time is 5 degrees centigrade per minute, the calcination time is 3 hours, and naturally cooled to room temperature.

[0045] The micro-nano powder material CoZn-LDHs-ZIF@C-200 prepared in Example 3, the electron microscope photo is as follows Picture 1-1 As shown, CoZn-LDHs-ZIF@C-200 still maintains a multi-level spherical structure, and a smooth and rough ZIF structure exists. figure 2 The X-ray diffraction pattern of this sample in CoZn-LDHs-ZIF@C-200, image 3 is the CoZn-LDHs-ZIF specific surface area test chart, from which the BET area of this sample is calculated to be 915.8 m 2 / g. Figure 5 It is the HER and OER electrocatalytic performance test chart of the sample. Figure 6 It is the electrocatalytic water s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com