A kind of phosphide nano catalyst and preparation method thereof

A nano-catalyst and phosphide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of MOF-based electrocatalysts with few reports, achieve excellent multifunctional electrocatalytic performance, solve The effect of low ORR activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides the first phosphide nanocatalyst, and its preparation method is as follows:

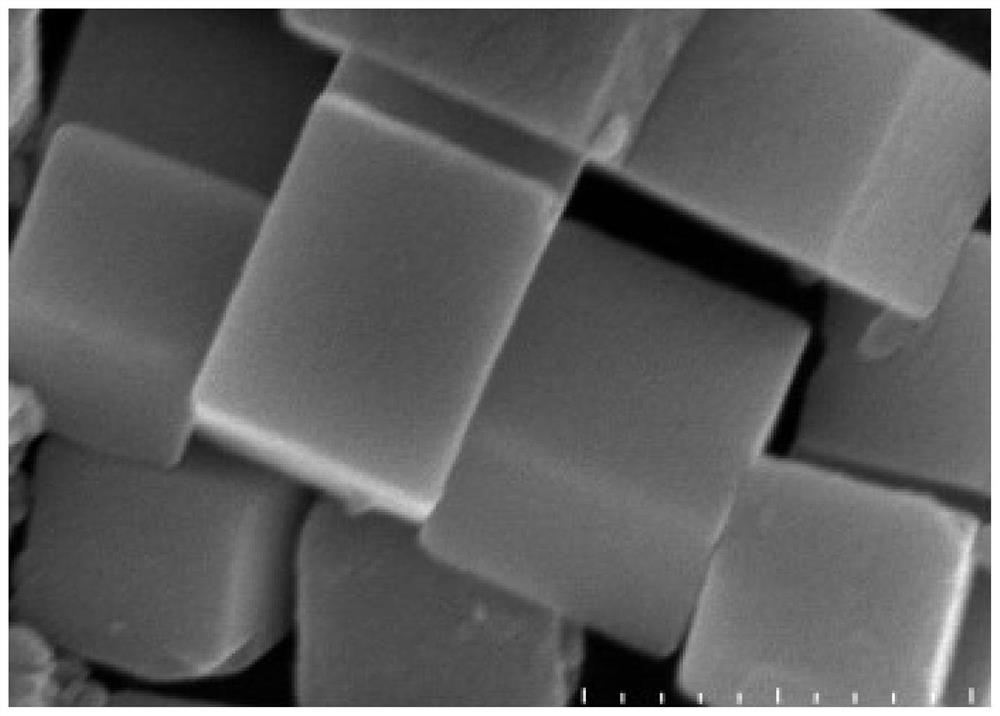

[0057] 1. Dissolve 3mmol of cobalt acetate and 4.5mmol of sodium citrate in 20ml of deionized water to obtain a solution; then, dissolve 2mmol of potassium cobaltcyanide in 20mL of deionized water, then quickly pour it into a solution and let it stand After 18 hours, filter and dry successively, the obtained Prussian blue analogue Co 3 [Co(CN) 6 ] 2 ;

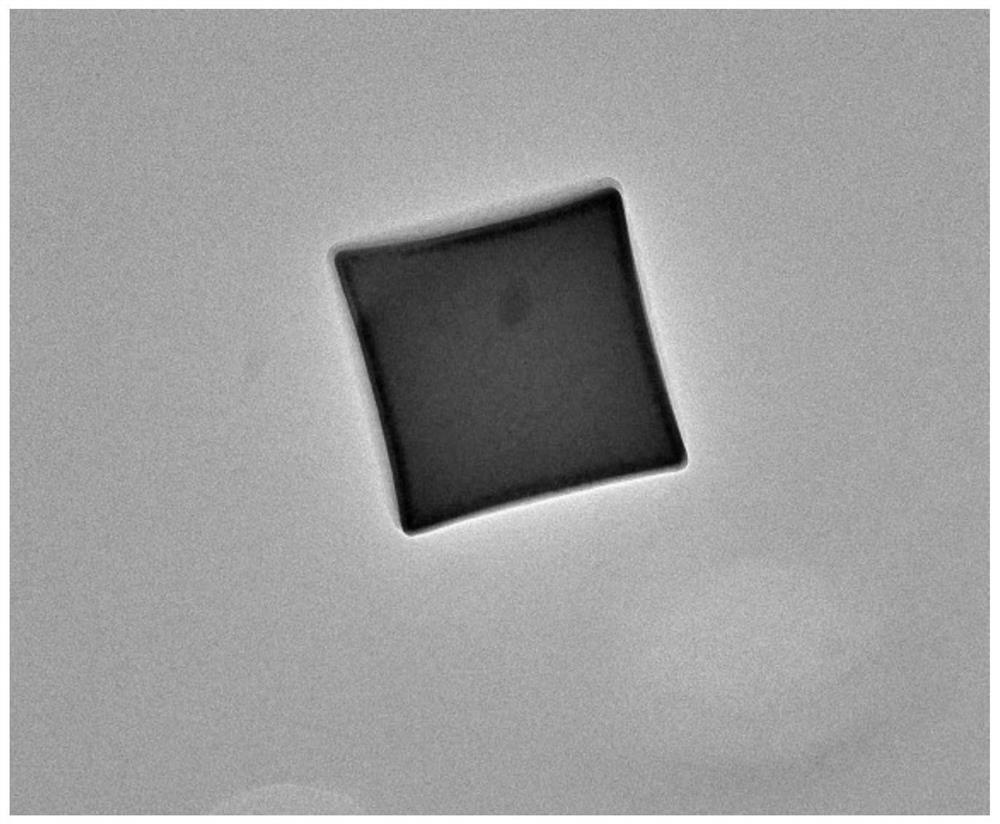

[0058] 2. Weigh the Co obtained in the above step 1. 3 [Co(CN) 6 ] 2 , placed in a tube furnace, in an air atmosphere, raised from room temperature to 400°C at a heating rate of 3°C / min, and kept at this temperature for 2h to obtain reactant 1;

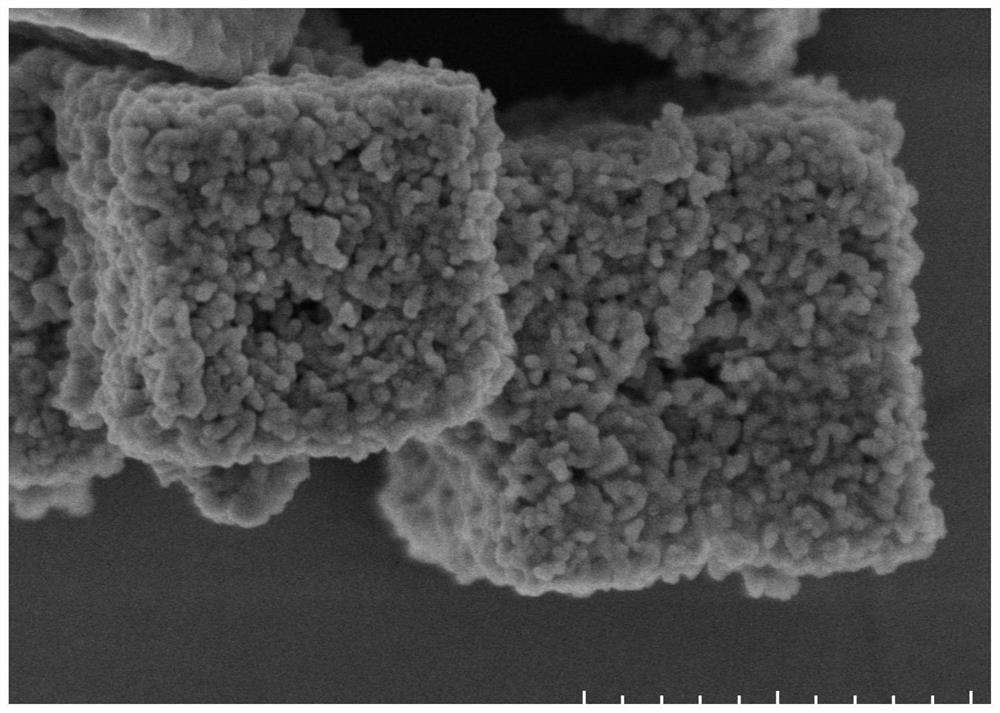

[0059] 3, reactant 1 and NaH obtained in step 2 2 PO 2 ·H 2 O is placed on both sides of the quartz boat, where NaH 2 PO 2 ·H 2 O On the air inlet side, place the quartz boat in a tube furnace, and raise the temperature from room temperature to 300°C at a rat...

Embodiment 2

[0065] The present embodiment provides the second phosphide nanocatalyst, and its preparation method is as follows:

[0066] 1. Dissolve 3mmol of cobalt acetate and 4.5mmol of sodium citrate in 20ml of deionized water to obtain a solution; dissolve 2mmol of potassium cobaltcyanide in 20mL of deionized water, then quickly pour it into a solution and let it stand for 18 hours , followed by filtration and drying treatment, the obtained Prussian blue analogue Co 3 [Co(CN) 6 ] 2 ;

[0067] 2. Weigh the Co obtained in the above step 1. 3[Co(CN) 6 ] 2 , placed in a tube furnace, in an air atmosphere, raised from room temperature to 400°C at a heating rate of 3°C / min, and kept at this temperature for 2h to obtain reactant 1;

[0068] 3. Treat the reactant 1 obtained in step 2 with NaH 2 PO 2 ·H 2 O is placed on both sides of the quartz boat, where NaH 2 PO 2 ·H 2 O On the air inlet side, place the quartz boat in a tube furnace, and raise the temperature from room temperatu...

Embodiment 3

[0073] The present embodiment provides the third phosphide nanocatalyst, and its preparation method is as follows:

[0074] 1. Dissolve 3mmol of cobalt acetate and 4.5mmol of sodium citrate in 20ml of deionized water to obtain a solution; dissolve 2mmol of potassium cobaltcyanide in 20mL of deionized water, then quickly pour it into a solution and let it stand for 18 hours , followed by filtration and drying treatment, the obtained Prussian blue analogue Co 3 [Co(CN) 6 ] 2 ;

[0075] 2. Weigh the Co obtained in the above step 1. 3 [Co(CN) 6 ] 2 , placed in a tube furnace, in an air atmosphere, raised from room temperature to 400°C at a heating rate of 3°C / min, and kept at this temperature for 2h to obtain reactant 1;

[0076] 3. Treat the reactant 1 obtained in step 2 with NaH 2 PO 2 ·H 2 O is placed on both sides of the quartz boat, where NaH 2 PO 2 ·H 2 O On the air inlet side, place the quartz boat in a tube furnace, and raise the temperature from room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com