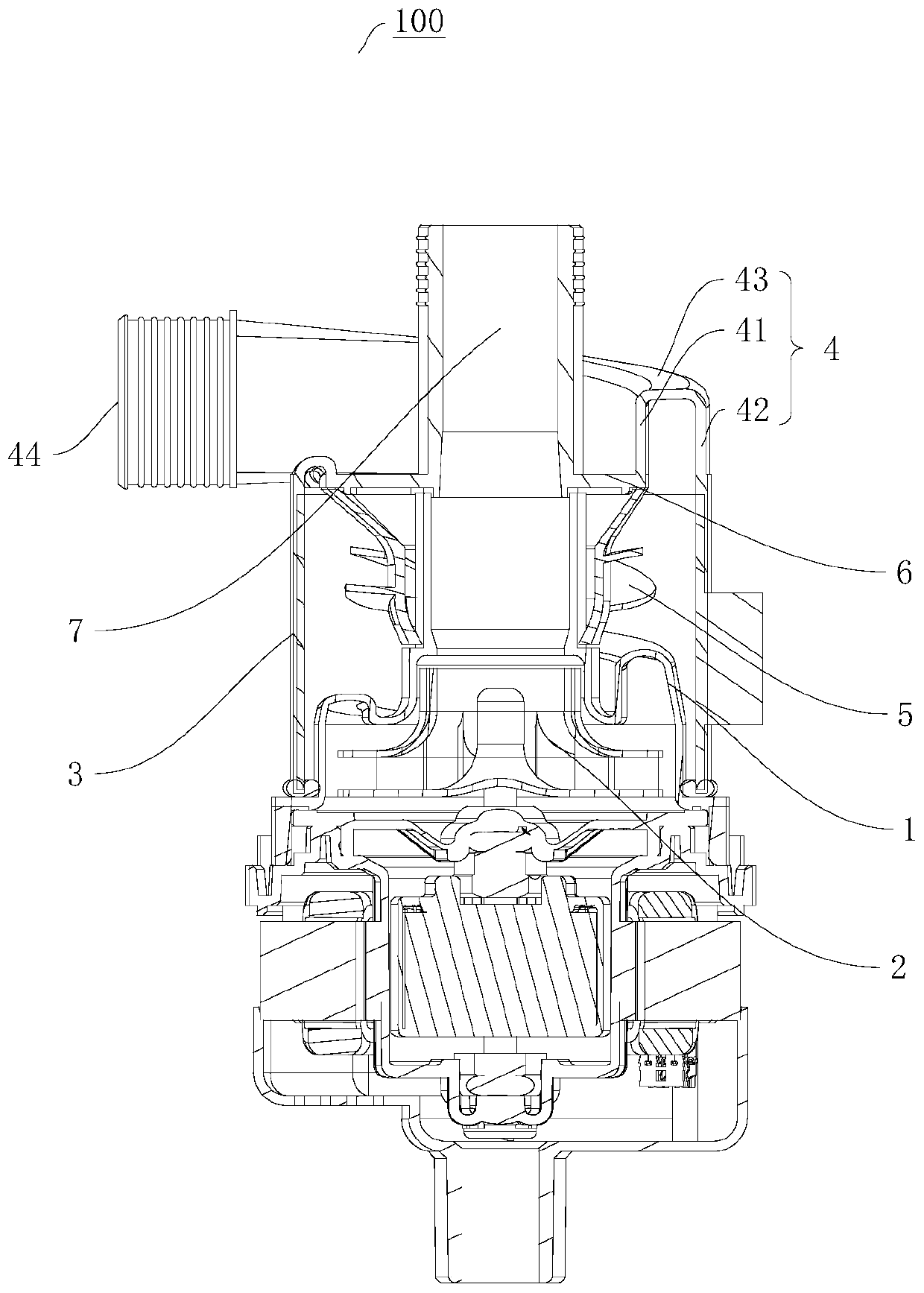

Heating pump and dishwasher

A heating pump and heating tube technology, which is applied in the direction of pumps, dishwashing machines/washing machines, pump components, etc., can solve problems such as hydraulic loss, and achieve the effect of improving hydraulic efficiency, smooth and regular water flow, and saving pump cavity space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

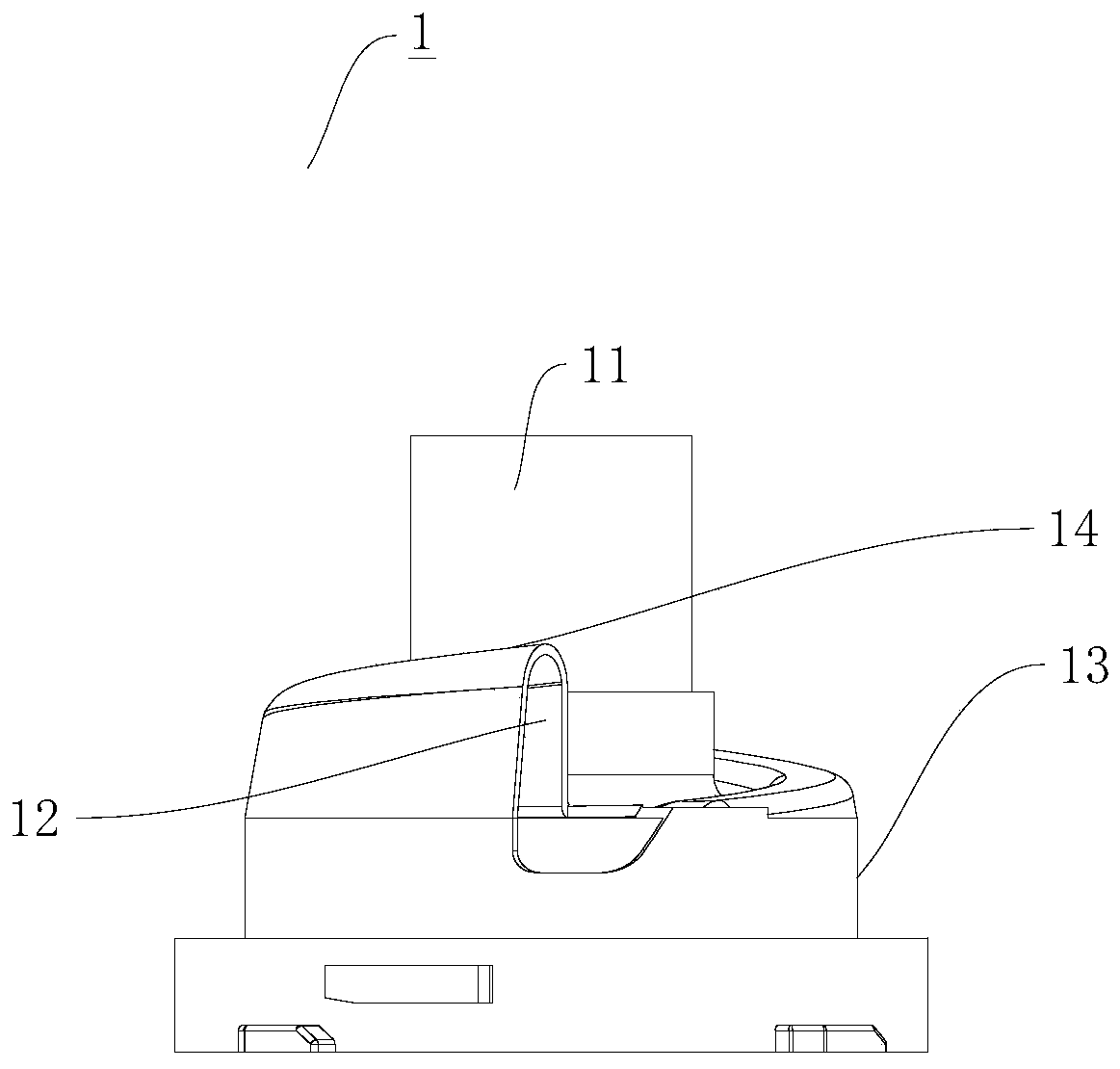

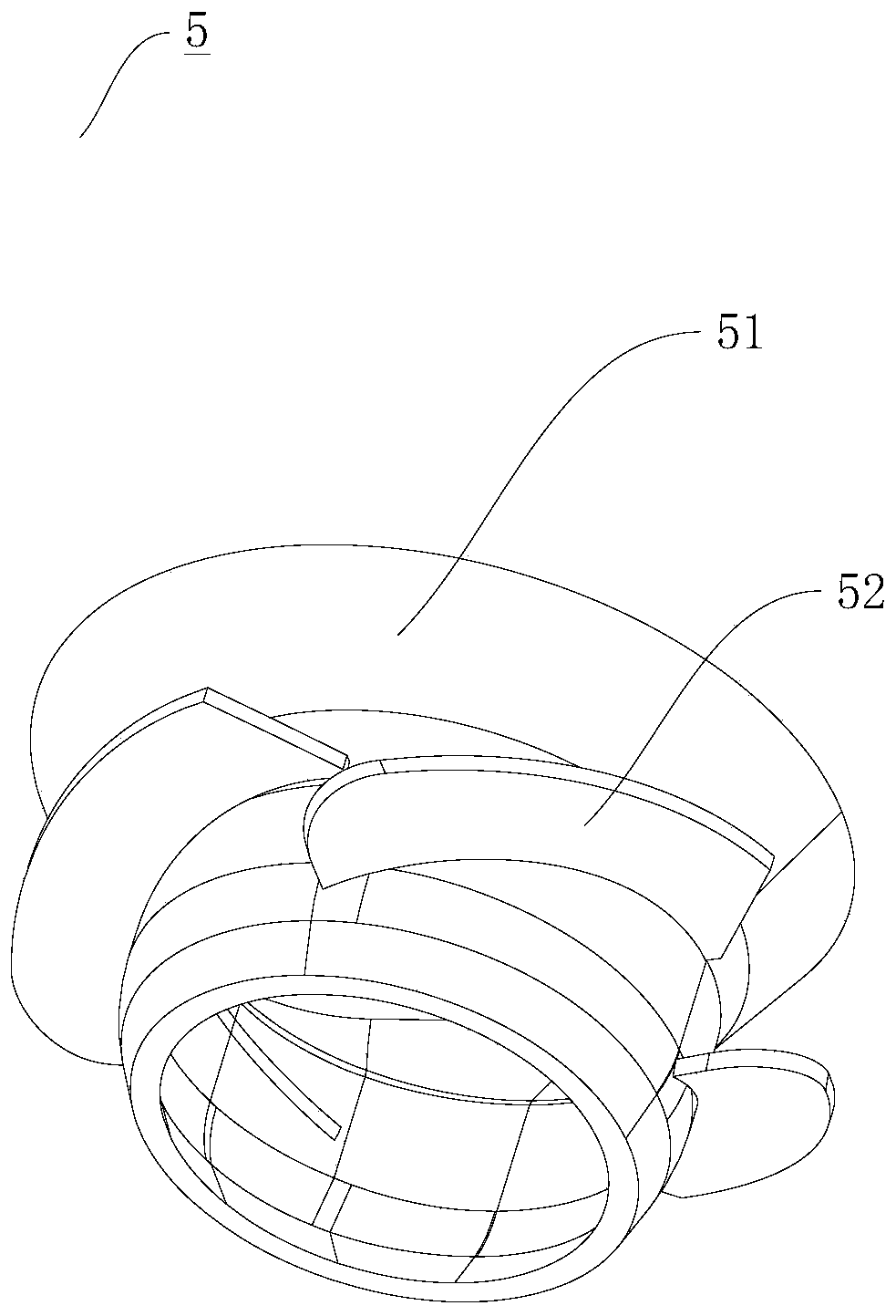

[0029] The heating power is an important parameter of the heat pump. In the production and use of the heat pump, it is usually increased according to the actual needs (such as user settings or program settings in different modes defaulted by the electrical appliances including the heat pump). The heating power of the heat pump is to meet the needs of obtaining different outlet water temperatures. Specifically, the power of the heating tube is increased. Usually, the power of the heating tube is increased by increasing the diameter and length of the tube, which will inevitably lead to a certain direction of the heat pump. Larger in size, thereby affecting the performance, size or appearance of the overall product.

[0030] However, there is another way to increase the heating power, which is to reduce the flow rate of the water flow, thereby prolonging the heat exchange time between the water flow and the heating pipe. Therefore, the present invention is dedicated to providing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com