Electric driving pump

An electric drive, pump shaft technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of hydraulic efficiency, vibration increase, impact on impeller installation, etc., to achieve the effect of increasing support points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

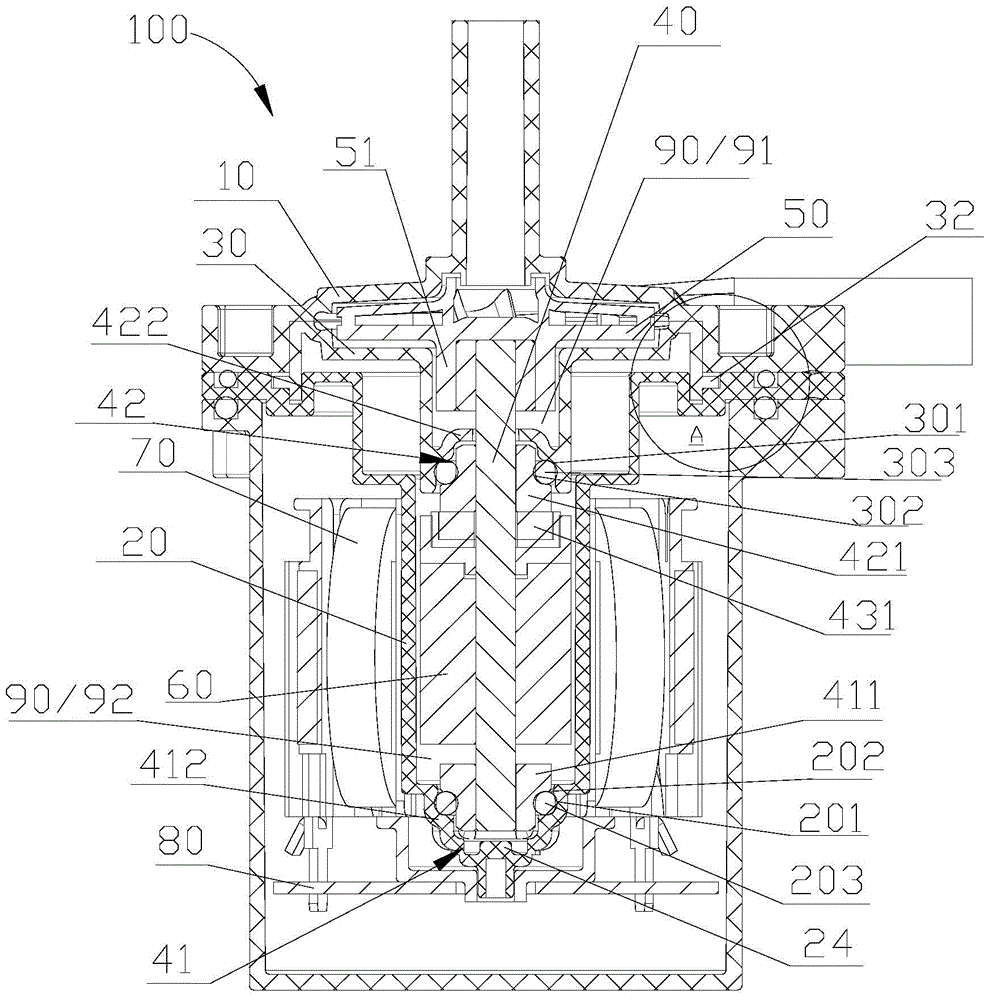

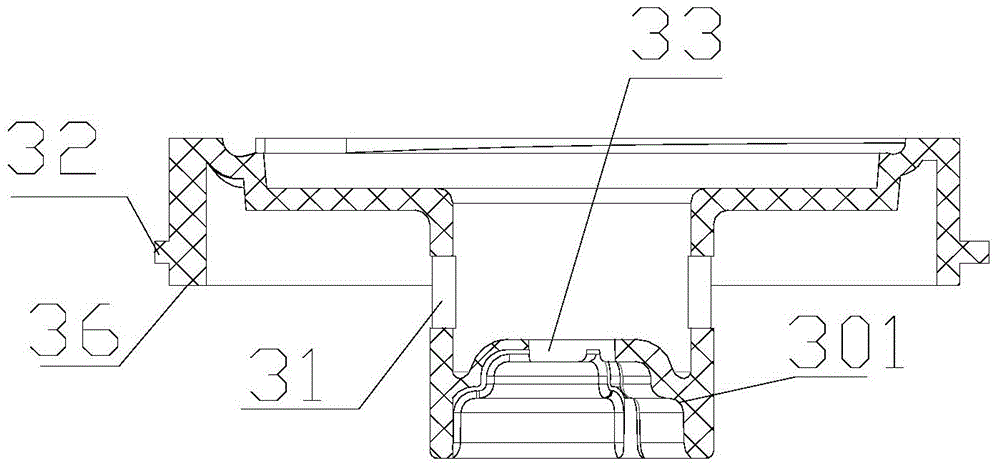

[0027] figure 1 It is a schematic structural diagram of an electric drive pump 100. The electric drive pump 100 includes an impeller cavity cover 10, an isolation sleeve 20, a pump shaft 40, an impeller 50, a rotor 60, a stator assembly 70, and an electric control board 80. The electric drive pump 100 has a flow The flow cavity 90 includes the space between the impeller cavity cover 10 and the isolation sleeve 20. The impeller 40 and the rotor 60 are arranged in the flow cavity 90. The rotor 60 can drive the impeller 50 to rotate around the central axis of the pump shaft 40. This embodiment Among them, the rotor 60 drives the impeller 50 to rotate together with the pump shaft 40, of course the pump shaft 40 can also be stationary, the rotor 60 drives the bearing sleeve and the impeller 50 sleeved on the outer peripheral surface of the pump shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com