Environmental-friendly pipeline outer wall derusting device for buildings

An environmentally friendly technology for the outer wall of the pipeline, applied in metal processing equipment, grinding/polishing equipment, grinding workpiece supports, etc., can solve the problems affecting the service life and quality of the pipeline, poor safety performance, low work efficiency, etc. It is convenient for production, popularization and use, the fixing of pipelines is safe, and the function is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

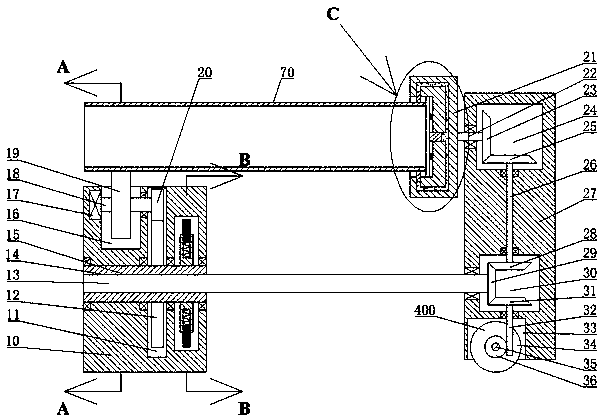

[0021] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

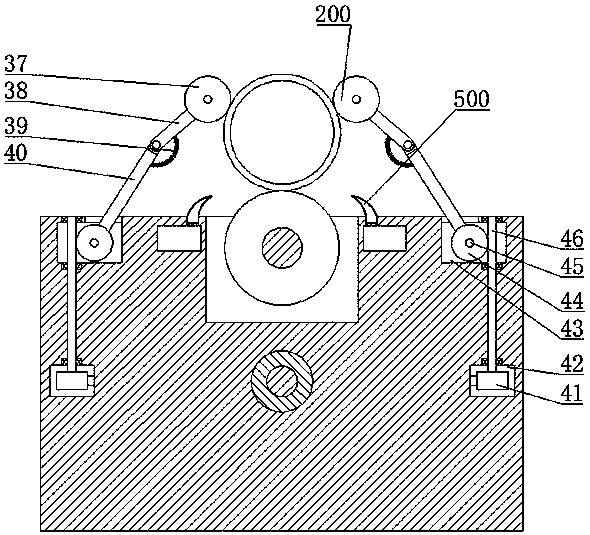

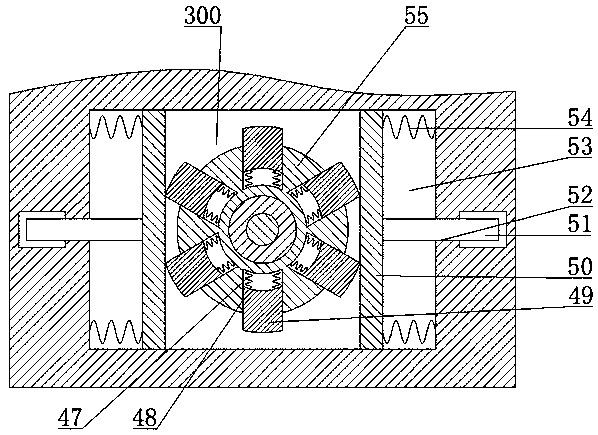

[0022] A kind of environment-friendly pipeline outer wall derusting equipment for construction described in conjunction with accompanying drawings 1-4 includes a fuselage 10 and a sliding frame 27 slidably arranged on the right side of the fuselage 10, and the inner opening of the fuselage 10 is upward A grinding cavity 16 is provided, and a grinding block 19 is rotatably arranged in the grinding cavity 16. A swing cavity 43 is arranged in the front and rear end walls of the grinding cavity 16, and a clamping mechanism 200 is arranged in the swing cavity 43. The clamping mechanism 200 includes two swing rods 40 that can swing in opposite directions in the two swing chambers 43 at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap