Parallel flow heat exchanger, air conditioner with the same and control method of air conditioner

A technology of parallel flow heat exchanger and air conditioner, which is applied in the direction of indirect heat exchanger, heat exchanger type, refrigerator, etc., can solve the problems of difficult frost removal, limited effect, and long time consumption, so as to speed up the defrosting speed, The effect of obvious effect and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

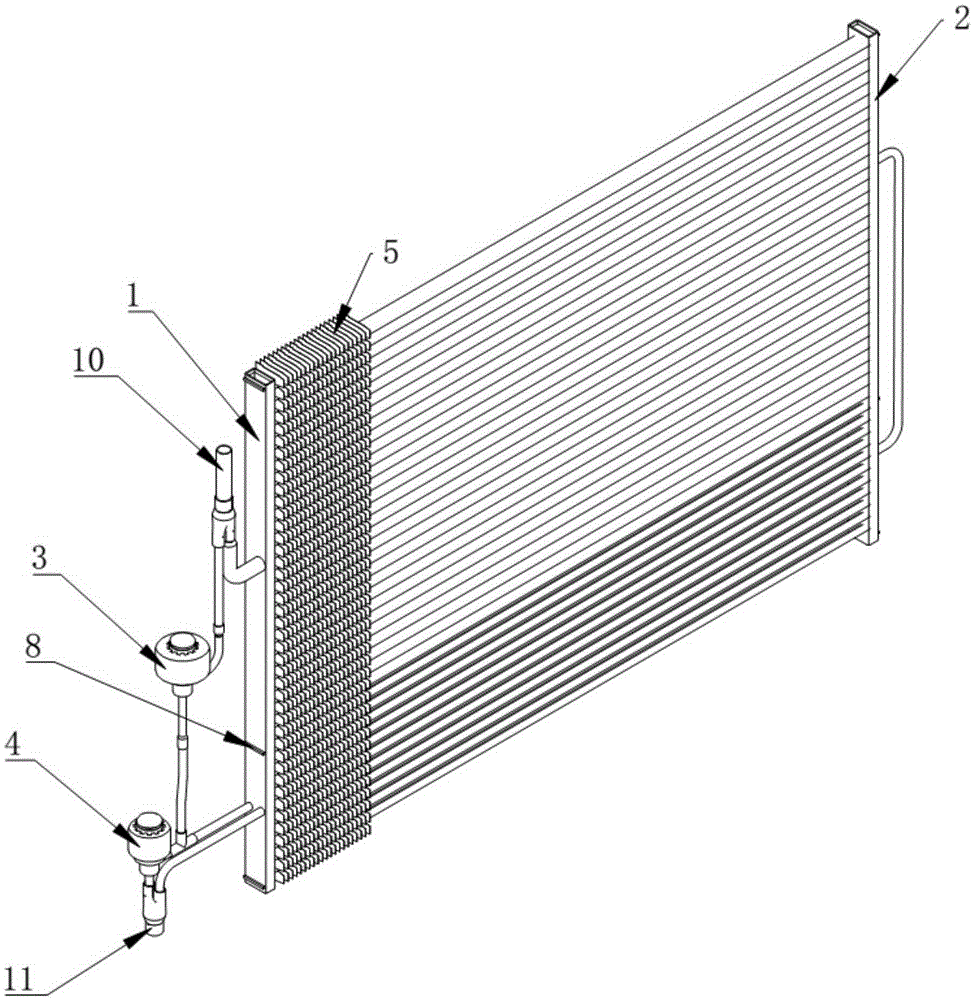

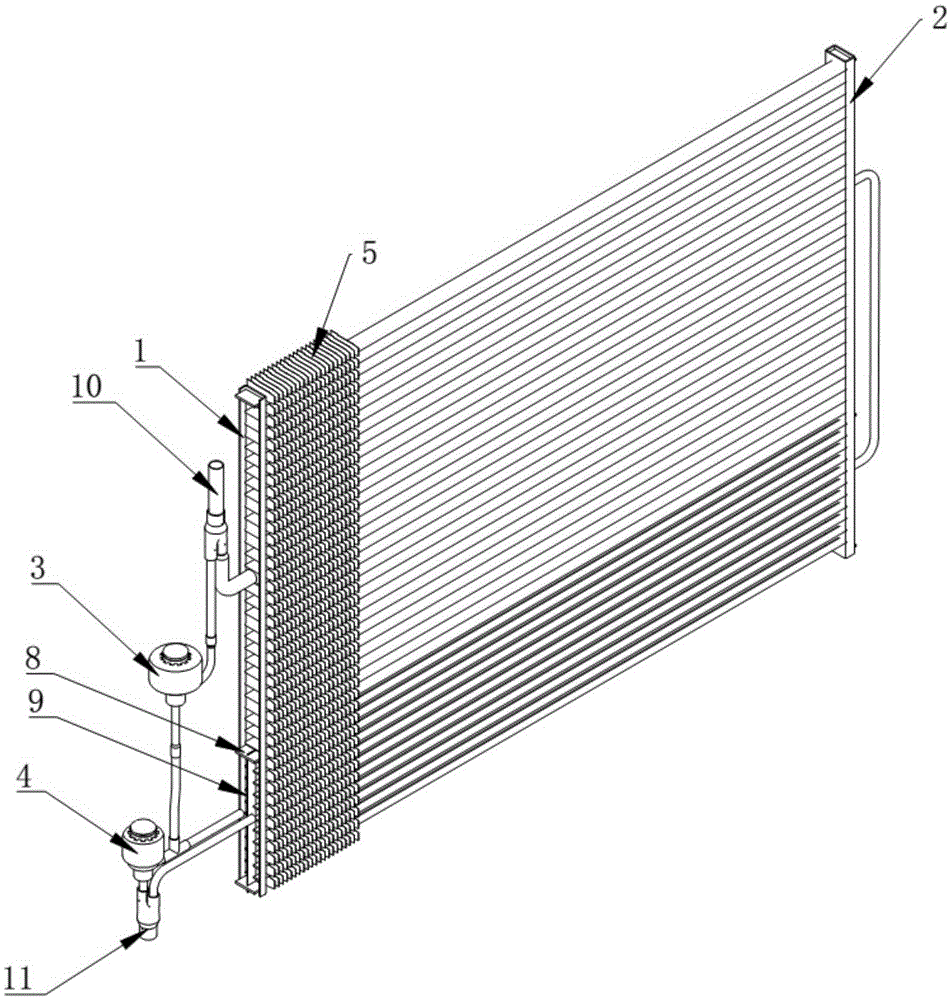

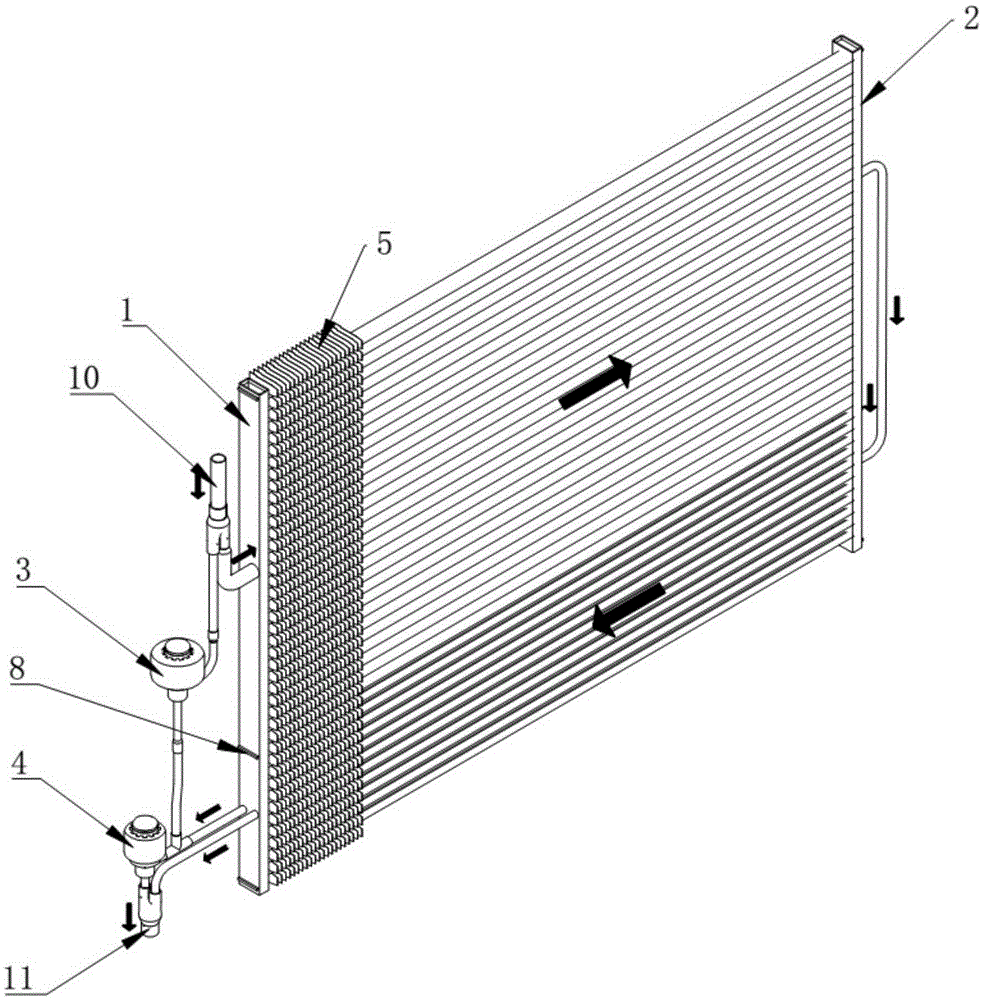

[0043] Such as figure 1 , figure 2 As shown, a parallel flow heat exchanger includes a first header 1 and a second header 2 arranged vertically side by side and a plurality of horizontally arranged flat tubes, and the two ends of the plurality of flat tubes are connected respectively The first header 1 and the second header 2, a plurality of flat tubes are also inserted with a plurality of fins 5 laterally, and the first header 1 is externally connected with a first interface 10 and a second The interface 11 also includes a transverse partition 8 and a vertical partition 9, the transverse partition 8 is arranged laterally in the middle between the first header 1 and the second header 2, and connects a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com