A device and method for separating layers of a thermal recovery well

A technology of isolation device and layered section, which is used in sealing/isolation, earth-moving drilling, wellbore/well components, etc., can solve the problems of short sealing section, no coupling, steam leakage, etc., and achieve sealing force Large, guaranteed to unpack, to avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

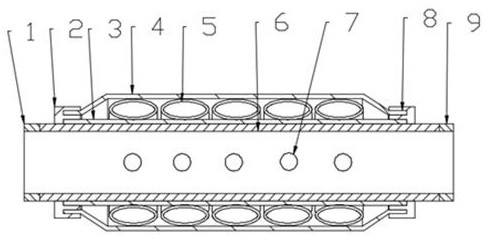

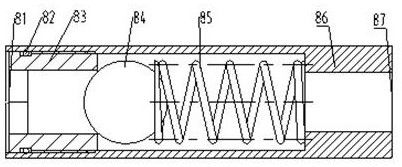

[0028] Example 1: the present invention provides a kind of technical scheme: refer to figure 1 , image 3 , Figure 4 , multi-channel parallel steam injection expansion steam injection packer, the upper joint 1 is connected to the upstream steam injection string to ensure that the injected steam enters the packer from this end, the upper joint 1 is connected to the central pipe 6, and the central pipe 6 is connected to the The lower joint 9 provides a smooth channel for the injected steam and supports and protects the external high-temperature-resistant sealing material inner sealing cylinder 3 and high-temperature-resistant sealing material outer sealing cylinder 4, and passes through the temperature-resistant metal upper shoulder guard ring 2 and the temperature-resistant metal lower The shoulder guard ring 8 seals and compresses the two ends of the sealing cylinder to prevent steam channeling. The prevention of steam channeling here refers to preventing the steam channeli...

example 2

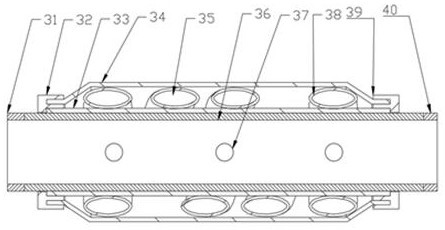

[0031] Example 2: the present invention provides a kind of technical scheme: refer to figure 2 , image 3 , Figure 5 , a multi-channel parallel steam injection expansion steam injection packer. The upper joint 31 is connected to the upstream steam injection string to ensure that the injected steam enters the packer from this end. The upper joint 31 is connected to the center pipe 36, and the center pipe 36 is connected to the The lower joint 40 provides an unobstructed channel for the injected steam and supports and protects the inner wall 33 of the high-temperature-resistant sealing material sealing cylinder and the outer sealing cylinder 34 of high-temperature-resistant sealing material, and passes through the temperature-resistant metal upper shoulder guard ring 32 and the temperature-resistant metal The lower shoulder guard ring 39 seals and compresses the two ends of the sealing cylinder to prevent steam channeling. A spiral oval metal sealing ring 35 and an oval meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com