Multi-layer comb-tooth-type three-dimensional garage

A three-dimensional garage and comb-tooth technology, which is applied to buildings, building types, buildings, etc. where cars are parked, can solve the problems of space waste, inability to realize parking, and reduced space utilization, so as to reduce parking costs and improve space utilization , the effect of significant economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The vertical, horizontal, and vertical directions mentioned in this article are all based on figure 1 The orientations shown are for reference only. The direction consistent with the parking of the car in the horizontal plane is the longitudinal direction; the direction perpendicular to the parking of the car in the horizontal plane is the horizontal direction; the direction perpendicular to the horizontal plane is the vertical direction.

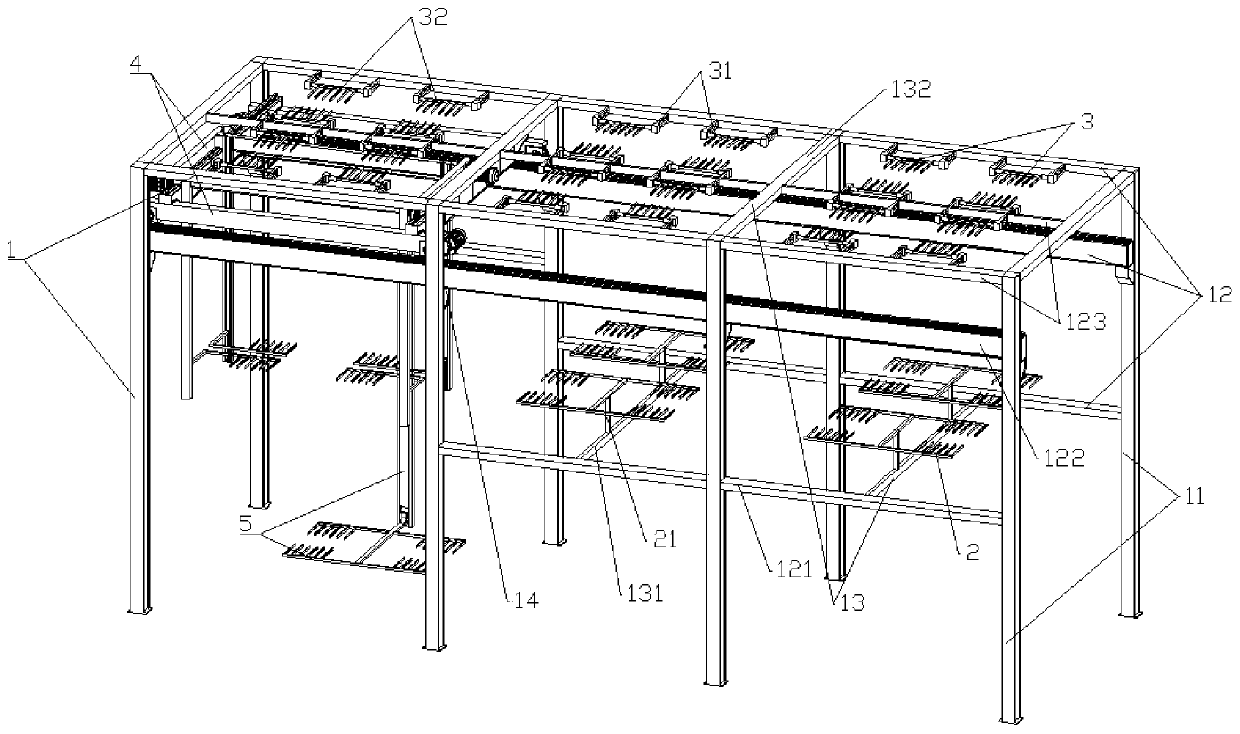

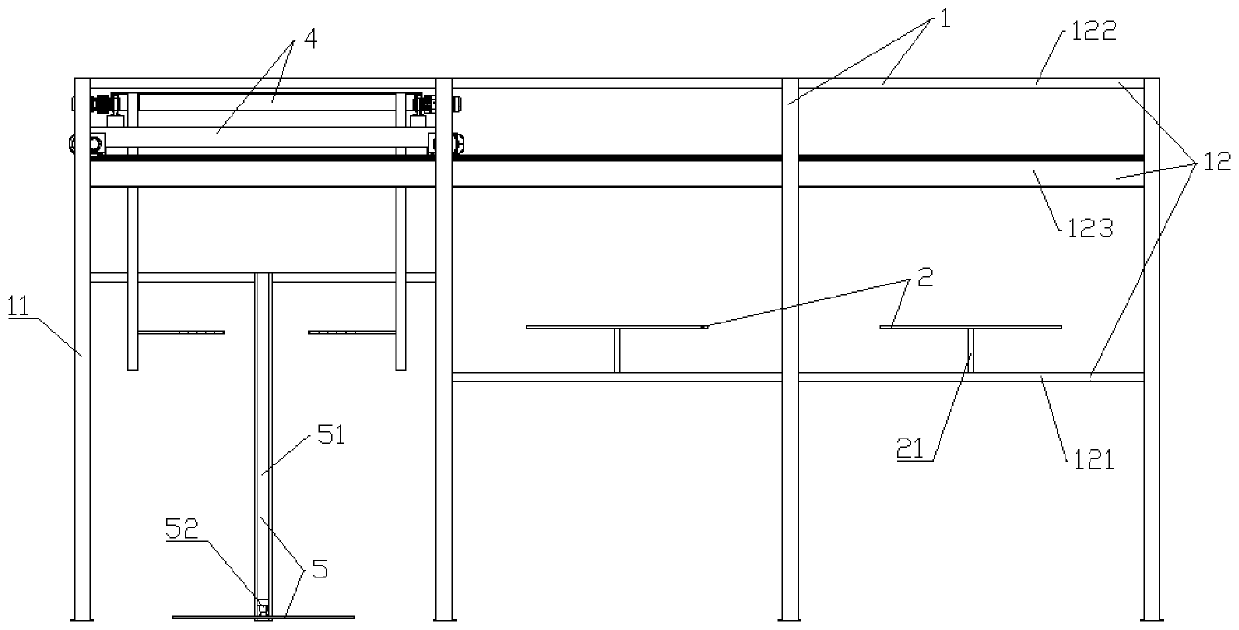

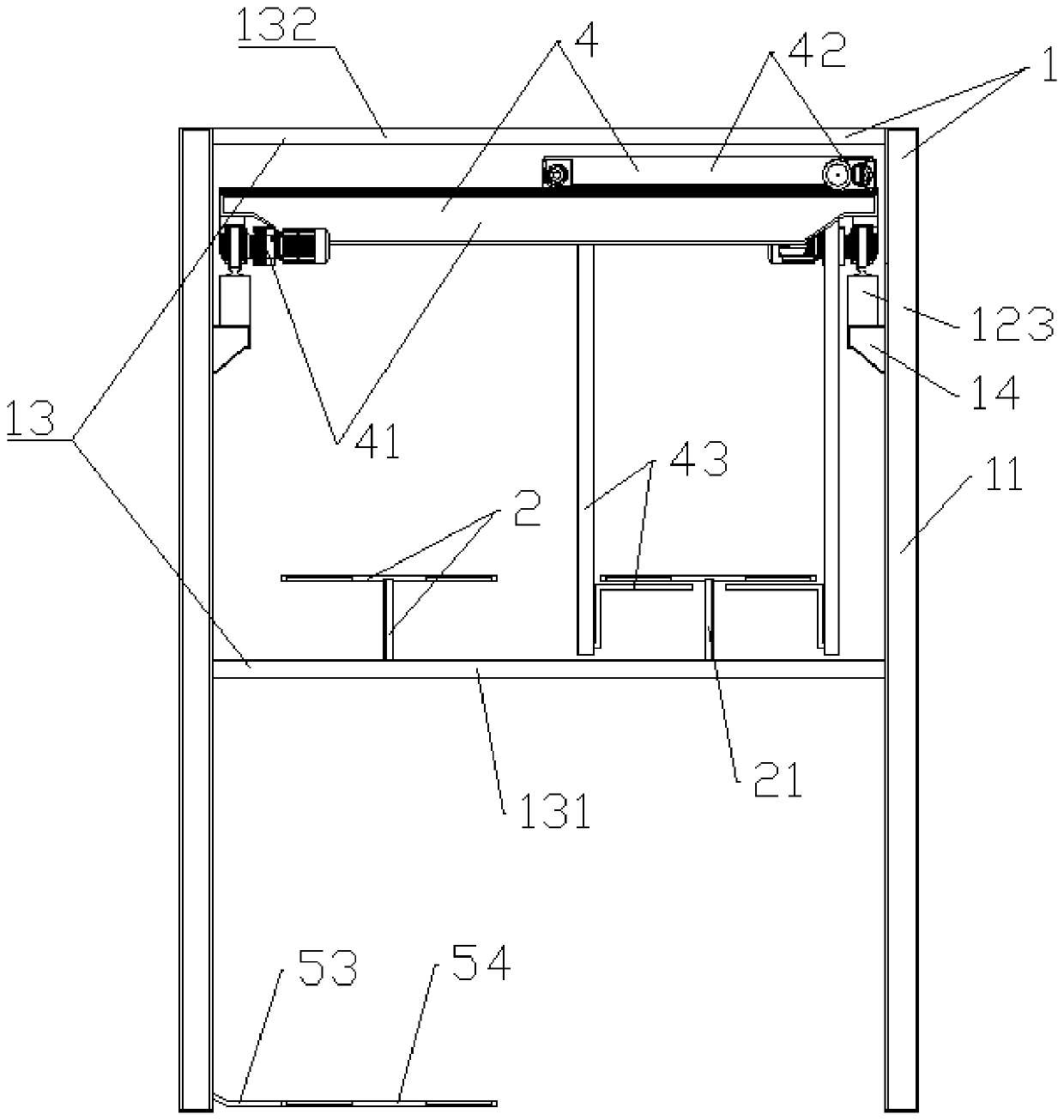

[0080] see Figure 1-Figure 12 , a multi-storey comb-toothed three-dimensional garage, including a frame assembly 1 and a middle layer comb-tooth type parking device 2 arranged on the frame assembly 1, an upper layer comb-tooth type parking device 3, a handling device 4 and a ground lifting device 5 . The frame assembly 1 is composed of several assembly uprights 11 fixed on the installation plane, and several assembly longitudinal beams 12 and assembly crossbeams 13 fixed on the uprights. The assembly longitudinal beams 12 and asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com