A Multipoint Nonlinear Predictive Control System for Press

A non-linear prediction and control system technology, applied in presses, manufacturing tools, etc., can solve problems such as affecting the position accuracy of the slider, damage to the press and mold, reducing product quality, etc., to eliminate mechanical vibration and eliminate the slider plane. The effect of skewing and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

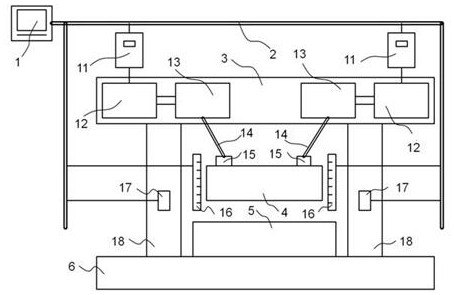

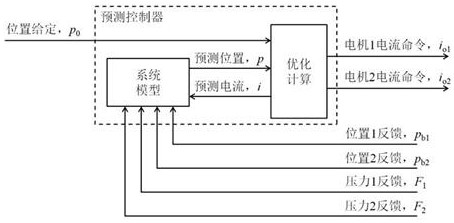

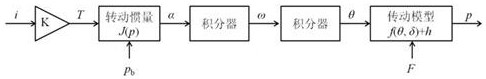

[0026] Aiming at the problem of skewing of the slider 4 caused by unbalanced multi-point pressure in the prior art, the present invention provides a multi-point full-closed-loop synchronous driving scheme. The present invention measures the stroke positions near different force application points of the slider 4, respectively controls the rotation speed and torque of the motor 12 corresponding to the different force application points, thereby ensuring that the stroke positions of the slider 4 at different force application points are equal.

[0027] This embodiment introduces a specific solution of the present invention by taking d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com