Intelligent card with protruding touch sense and manufacturing method thereof

A production method and technology for smart cards, applied in the field of smart cards, can solve the problems of complex three-stage process and high energy consumption, and achieve the effects of fine graphics and text, high production efficiency, and not easy to scratch and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

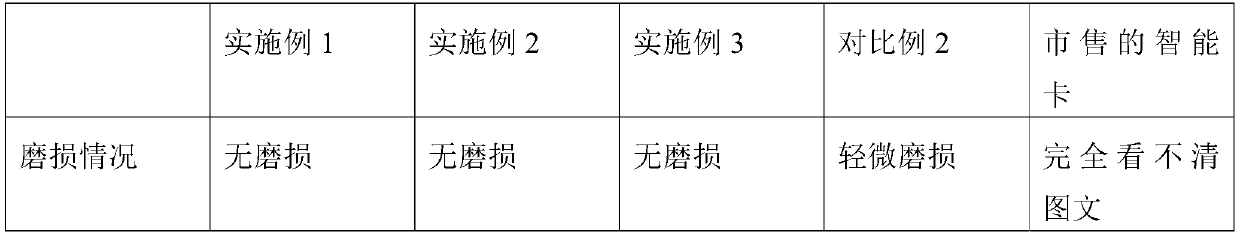

Examples

Embodiment 1

[0036] A smart card with a raised touch, comprising a chip module, a hot-melt adhesive layer, an upper adhesive film layer, an upper printed substrate layer, an element layer, a lower printed substrate layer and a lower adhesive film layer that are sequentially stacked; wherein the upper printed A 3D printing layer is also included between the substrate layer and the adhesive film layer.

[0037] A method for manufacturing a smart card with raised touch, comprising the following steps:

[0038] (1) 3D printing (forming a 3D printing layer) on the surface of the PVC sheet or paper sheet as the upper printing substrate layer to form the required graphics and text, and then pasting a transparent PVC adhesive film (that is, the upper adhesive film layer) ), to protect the graphics and texts formed by 3D printing, to obtain product A, for standby;

[0039] (2) Paste a transparent PVC adhesive film (i.e. the lower adhesive film layer) on the surface of the PVC sheet or the paper sh...

Embodiment 2

[0047] A smart card with a raised touch, comprising a chip module, a hot-melt adhesive layer, an upper adhesive film layer, an upper printed substrate layer, an element layer, a lower printed substrate layer and a lower adhesive film layer that are sequentially stacked; wherein the upper printed A 3D printing layer is also included between the substrate layer and the upper adhesive film layer; a 3D printing layer is also included between the lower adhesive film layer and the lower printed substrate layer.

[0048] A method for manufacturing a smart card with raised touch, comprising the following steps:

[0049] (1) 3D printing (forming a 3D printing layer) on the surface of the PVC sheet or paper sheet as the upper printing substrate layer to form the required graphics and text, and then pasting a transparent PVC adhesive film (that is, the upper adhesive film layer) ), to protect the graphics and texts formed by 3D printing, to obtain product A, for standby;

[0050] (2) 3D...

Embodiment 3

[0058] A smart card with a raised touch, comprising a chip module, a hot-melt adhesive layer, an upper adhesive film layer, an upper printed substrate layer, an element layer, a lower printed substrate layer and a lower adhesive film layer that are sequentially stacked; wherein the upper printed A metal foil layer is also included between the substrate layer and the adhesive film layer.

[0059] A method for manufacturing a smart card with raised touch, comprising the following steps:

[0060] (1) Place a metal foil on the surface of the PVC sheet or paper sheet as the upper printing substrate layer (to form a metal foil layer), form the required graphics, and then paste a transparent PVC adhesive film (that is, gluing Film layer), to protect the graphics and text formed by placing the metal foil, and the obtained product A is for use;

[0061] (2) Paste a transparent PVC adhesive film (i.e. the lower adhesive film layer) on the surface of the PVC sheet or the paper sheet as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature range | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com