Method for constituting modular lamp box

A light box and box technology, which is applied in the directions of illuminated signs, instruments, display devices, etc., can solve the problems of dark shadows in the box and the inability to realize shadowless splicing, etc., and achieve easy installation and maintenance, simple structure, and uniform light emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution in the embodiment of the present invention will be clearly and completely described below in combination with the accompanying drawings in the embodiment of a method for constructing a modular light box of the present invention.

[0041] The front side and the rear side described in the embodiments of the present invention are based on the directions shown in the description of the drawings.

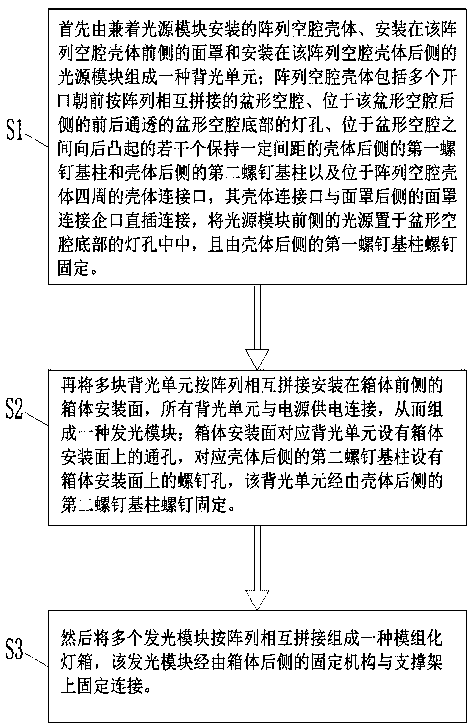

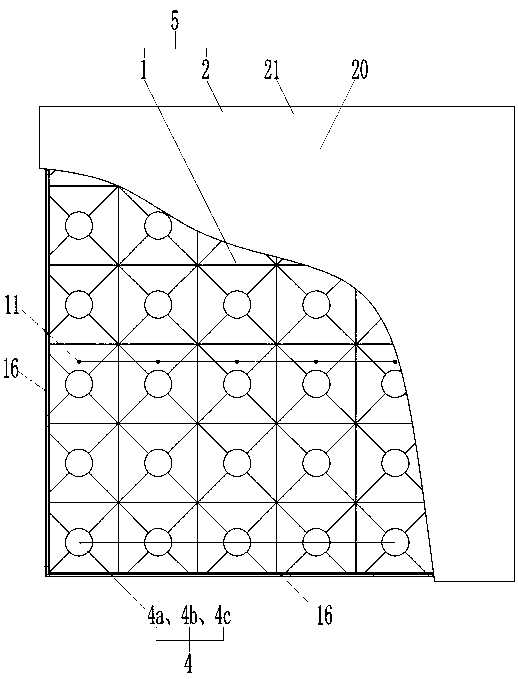

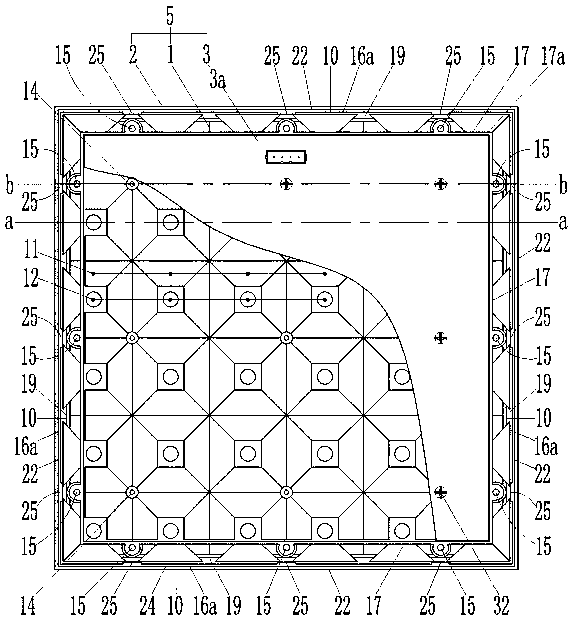

[0042] An embodiment of the method for forming a modular light box of the present invention, please refer to the attached figure 1 . First, if Figure 2 to Figure 9 As shown, an array cavity housing 1 installed with a light source module, a mask 2 installed on the front side of the array cavity housing 1, and a light source module 3 installed on the rear side of the array cavity housing 1 form a The backlight unit 5, wherein the array cavity housing 1 includes a plurality of basin-shaped cavities 11 with openings facing forward and splicing with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com