Side-light type backlight module group using LED light source

A technology of LED light source and backlight module, which is applied in the direction of optics, nonlinear optics, and printed circuits connected with non-printed electrical components, and can solve the problems of the distribution of bright areas and dark areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, invention is further described:

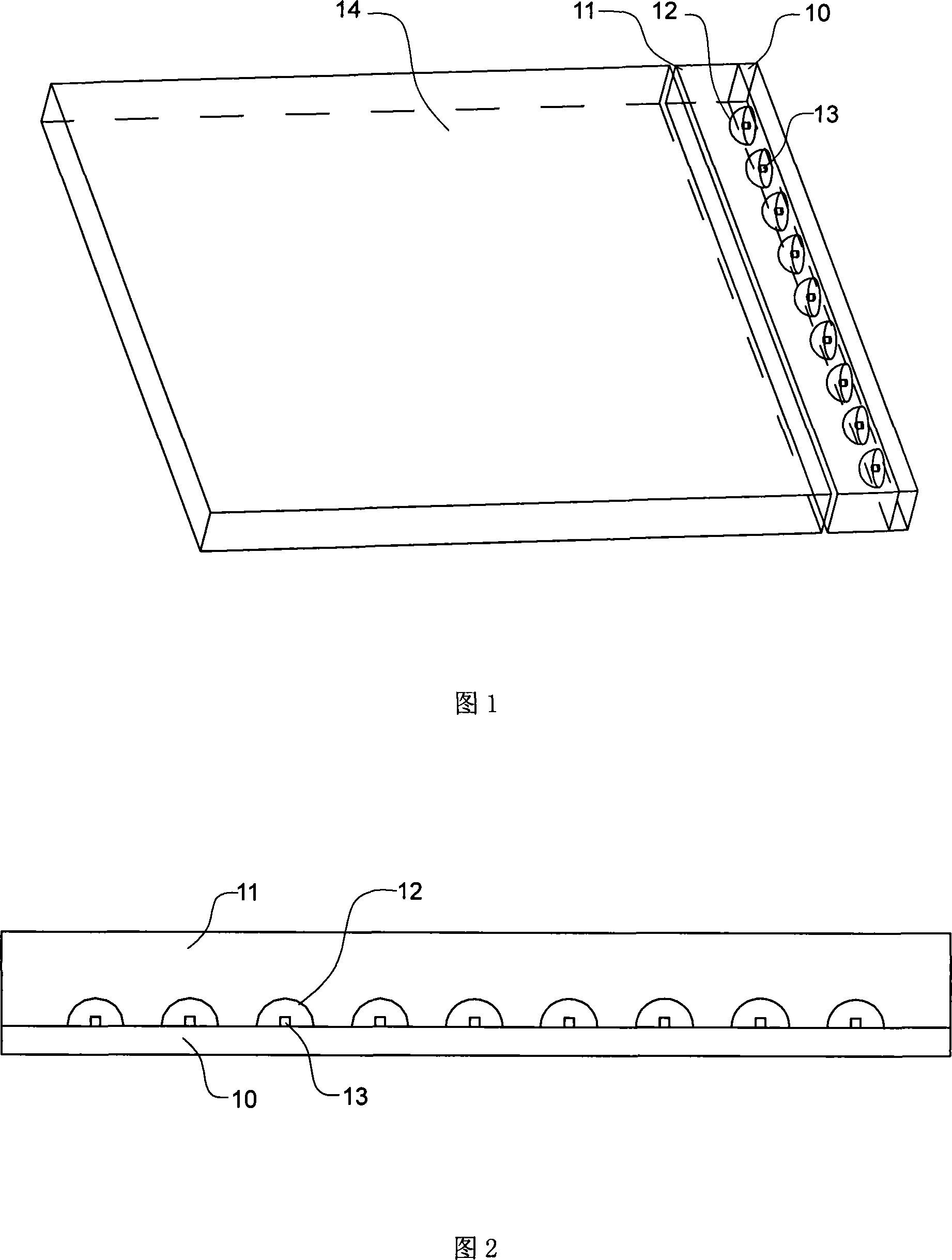

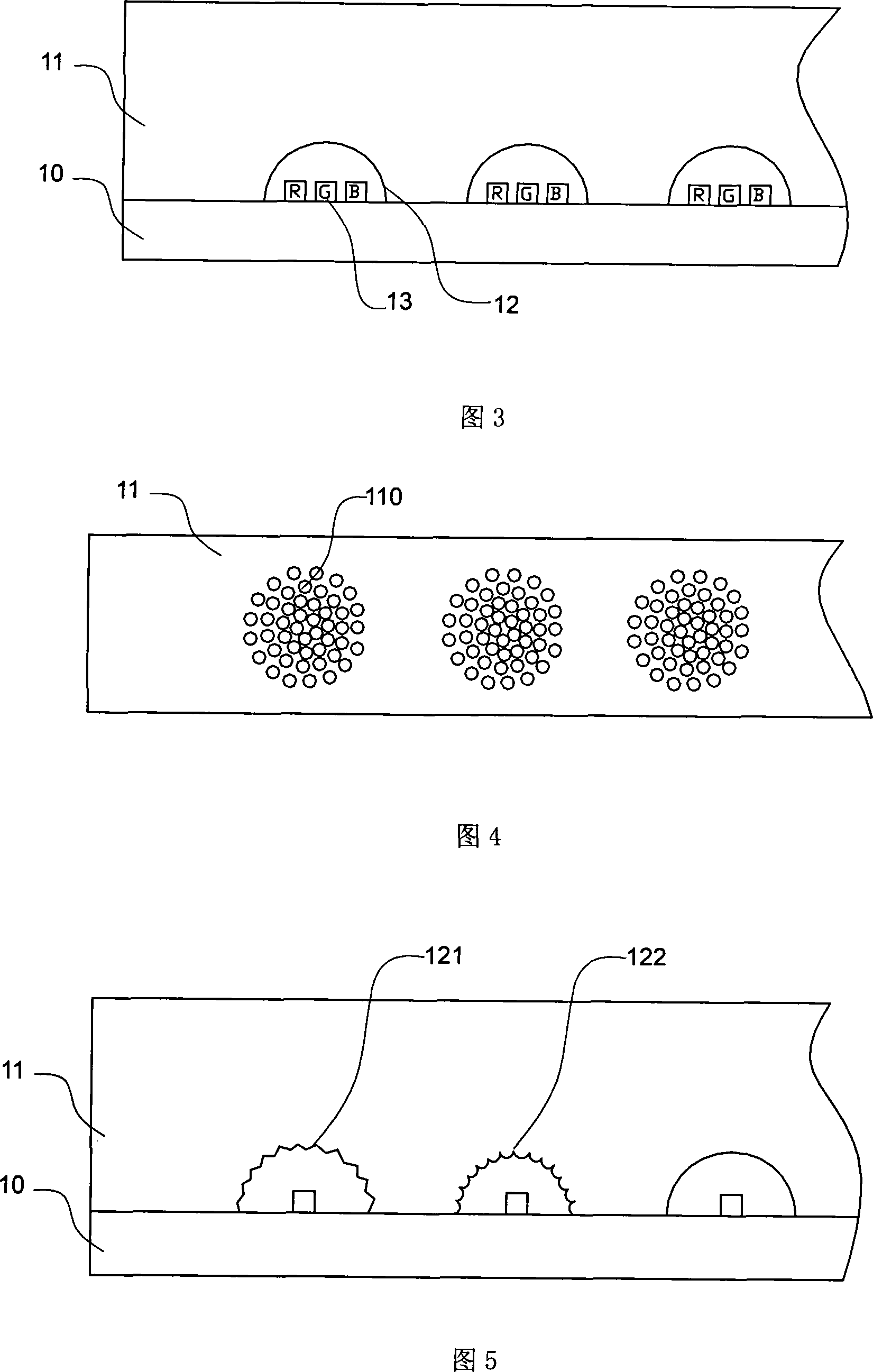

[0019] Fig. 1 is a schematic perspective view of an edge-lit backlight module using an LED light source of the present invention, and Fig. 2 is a schematic top view of the side-light backlight module using an LED light source in Fig. 1, and the light guide plate 14 is omitted in Fig. 2 , As shown in the figure, the edge-lit backlight module using LED light sources of the present invention mainly includes a PCB (printed circuit board) substrate 10 , a packaging structure 11 , a cavity 12 , LED chips 13 and a light guide plate 14 .

[0020] A plurality of LED chips 13 are fixed to the PCB substrate 10 at equal intervals by adhesive or solder, and then the electrical interconnection between the LED chips 13 and the PCB substrate 10 is realized by wire bonding, that is, direct chip on board COB (Chip On Board) packaging technology. The PCB substrate 10 is made of a metal-based or ceramic-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com