Non-nail assembling robot working station suitable for wooden boxes with multiple specifications

A technology of robots and workstations, applied in wood processing equipment, conveyors, manufacturing tools, etc., can solve the problems of low automation and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

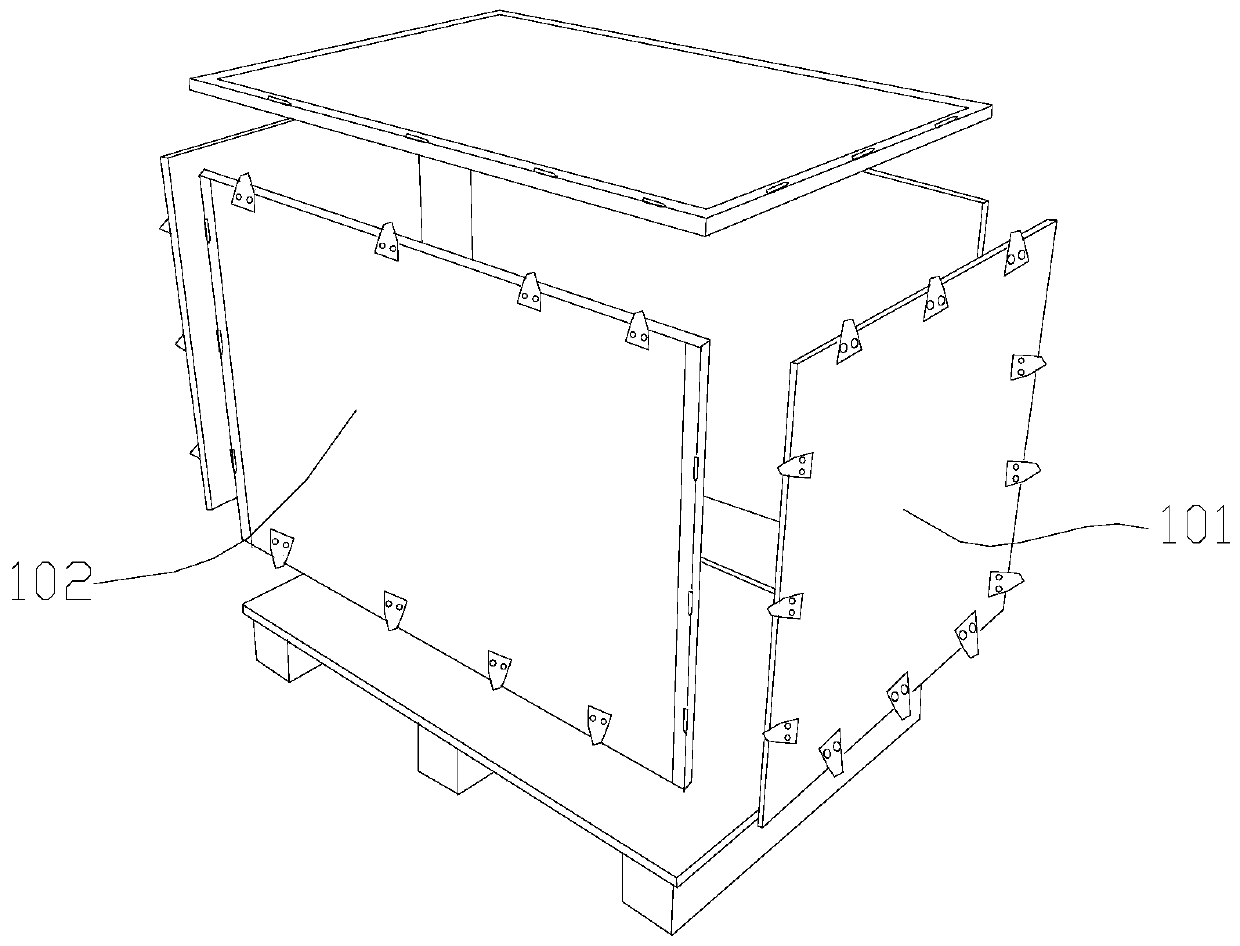

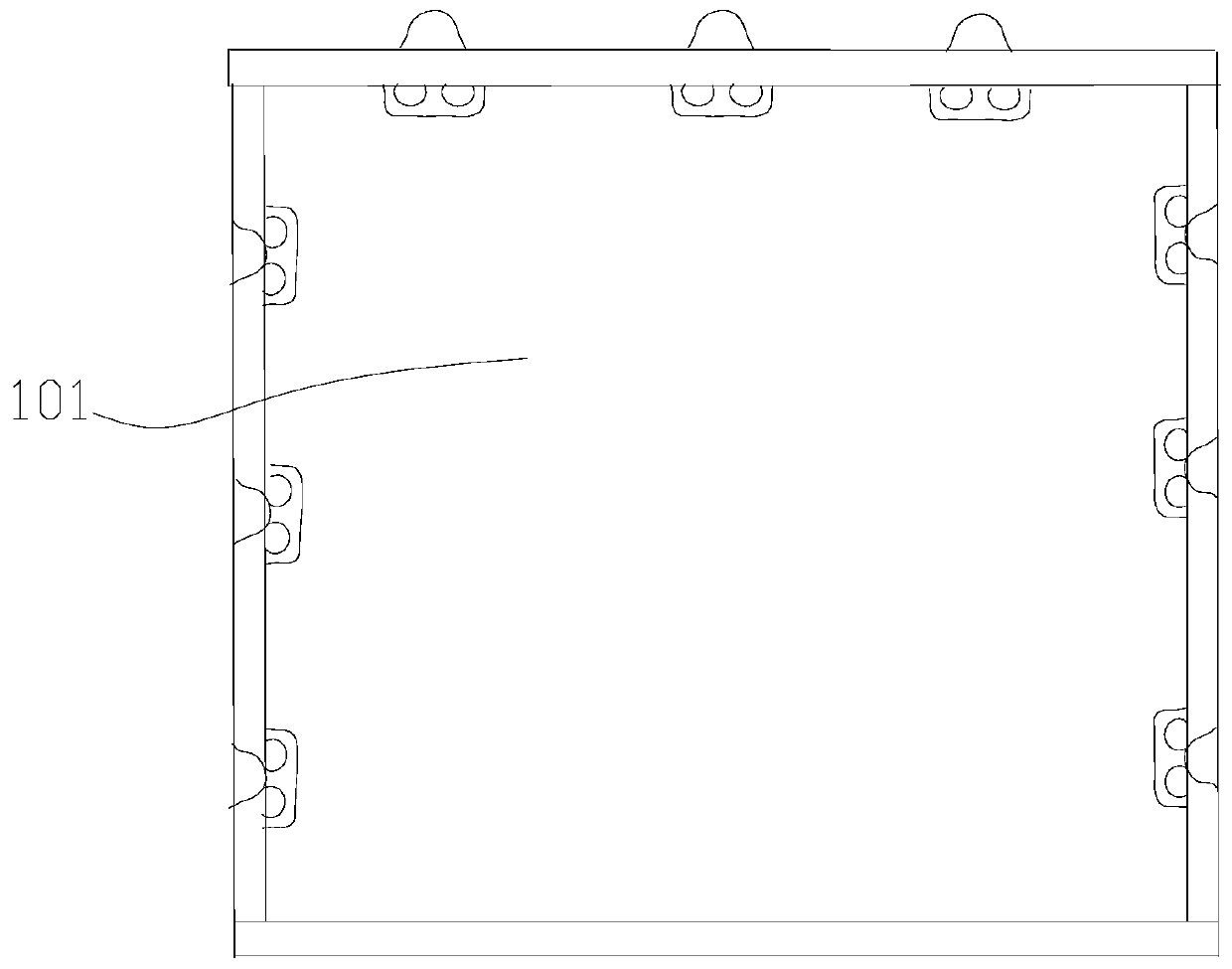

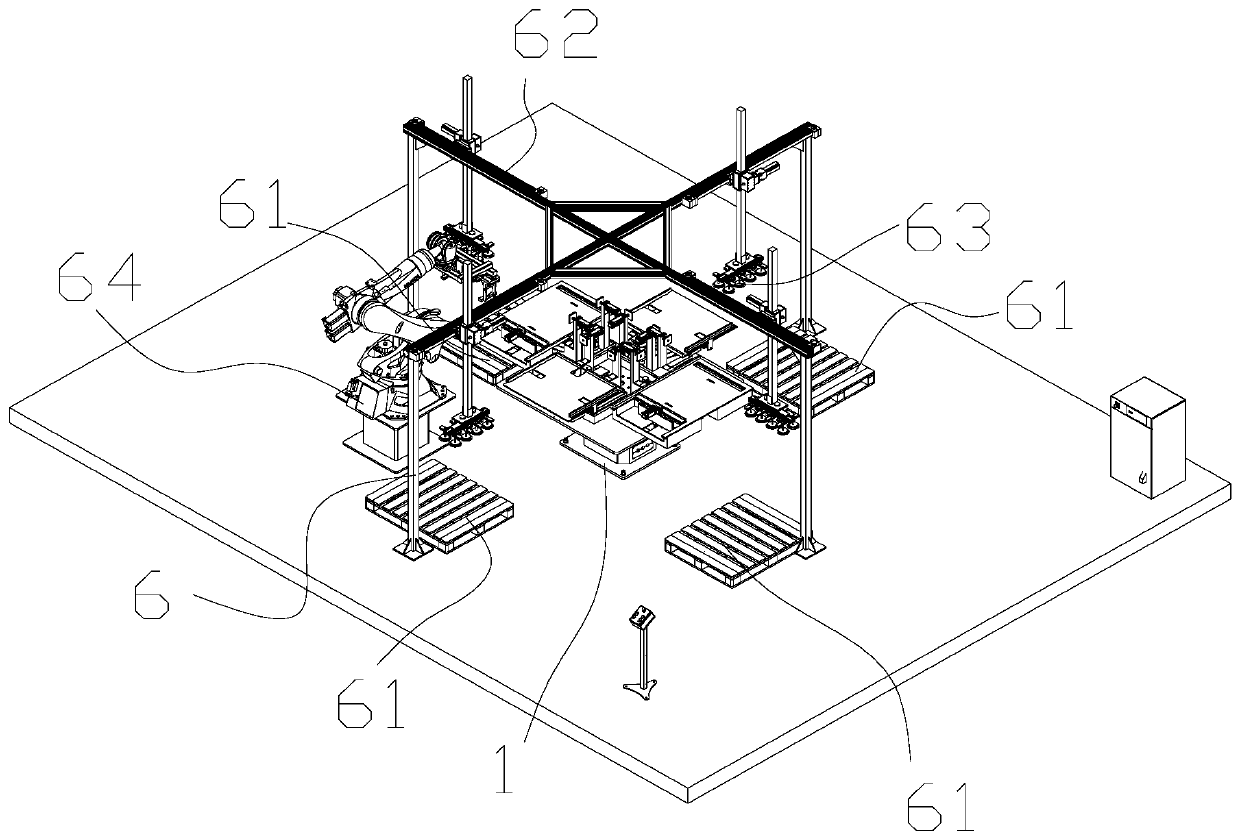

[0035] like Figures 1 to 10 , a nail-free assembly robot workstation suitable for multi-specification wooden boxes, the wooden box includes two symmetrically arranged first wooden box panels 101 with metal lugs on the sides and two symmetrically arranged sides with lug grooves The second wooden box board 102, the workstation includes a workbench 1, and the side of the workbench 1 is provided with a first inversion positioning table 20 for turning the first wooden box board 101 from a horizontal state to a vertical state and a second wooden box. The board 102 is turned from the horizontal state to the second turning positioning table 30 in the vertical state, and the metal lugs are inserted into the adjacent second wooden box before the first turning positioning table 20 carrying the first wooden box board 101 is turned over. In the lug groove of the board 102, the workbench 1 is provided with the first turning positioning table 20 and the second turning positioning stage 30 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com