Transmission belt forming die capable of reversible repeated installation and method for disassembling and assembling transmission belt

A technology for forming molds and transmission belts, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as low efficiency, high labor intensity, and cumbersome disassembly work, so as to improve the efficiency of disassembly and assembly, reduce labor intensity, Effect of Reduction in Assembly and Disassembly Work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

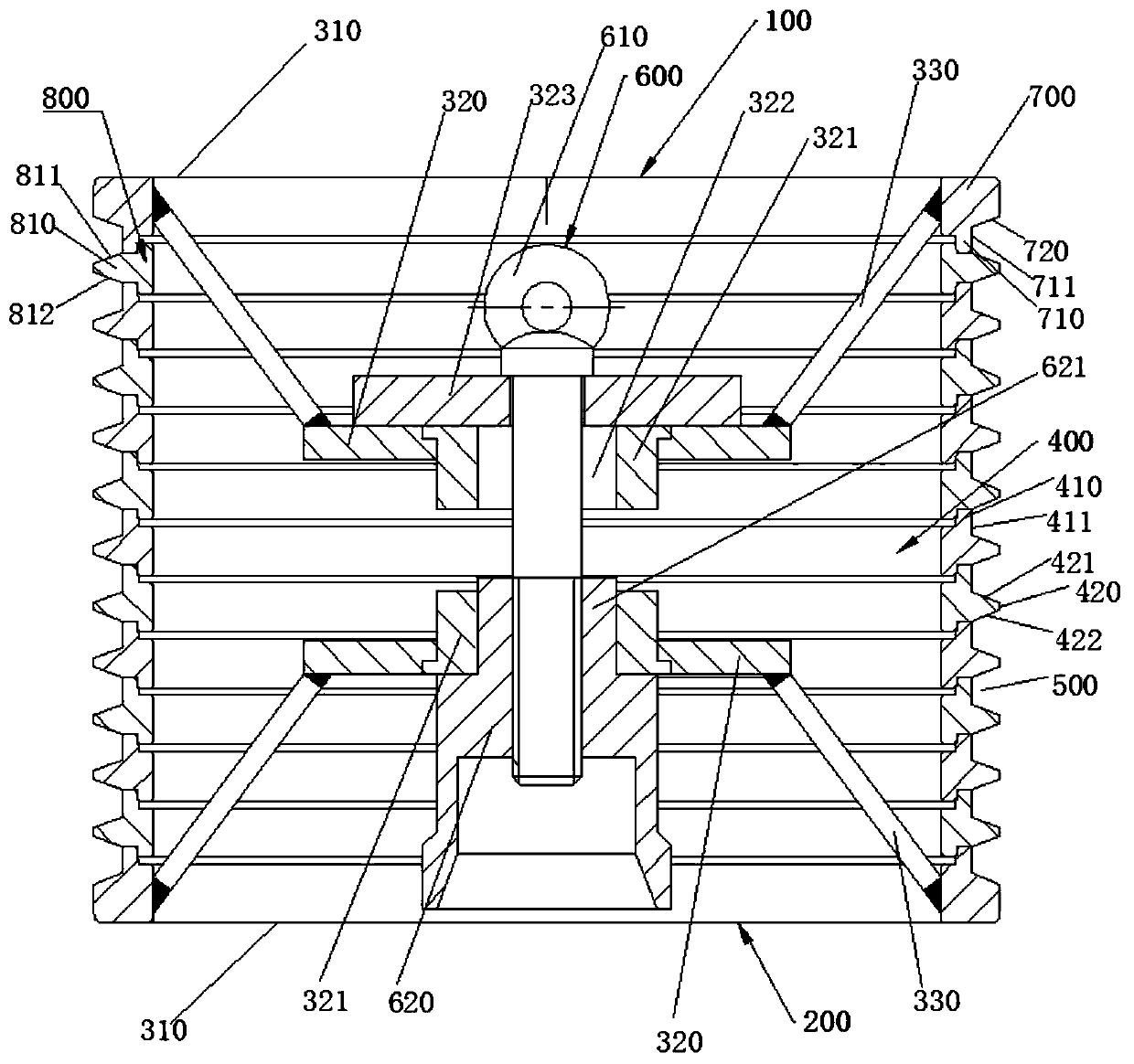

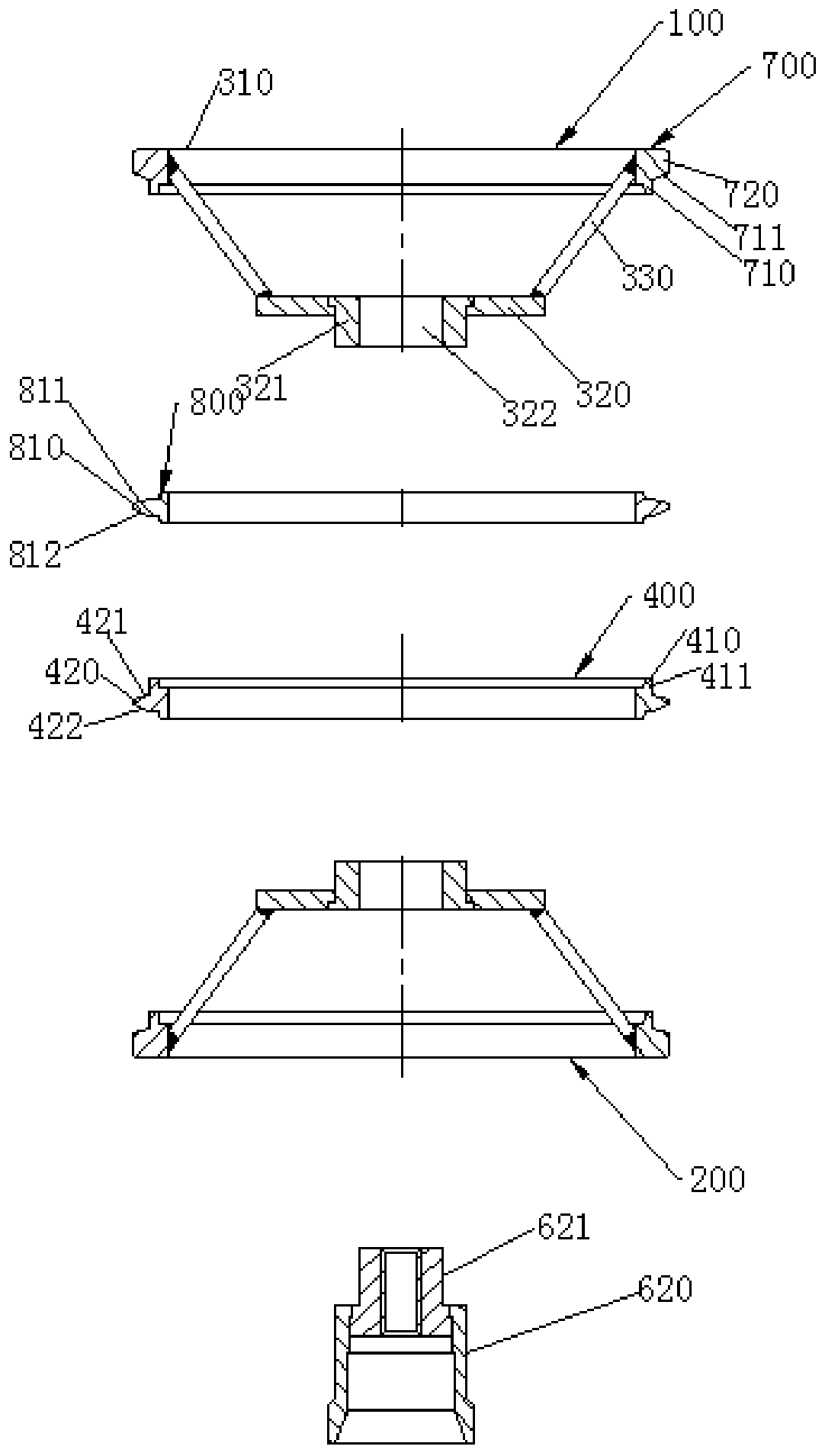

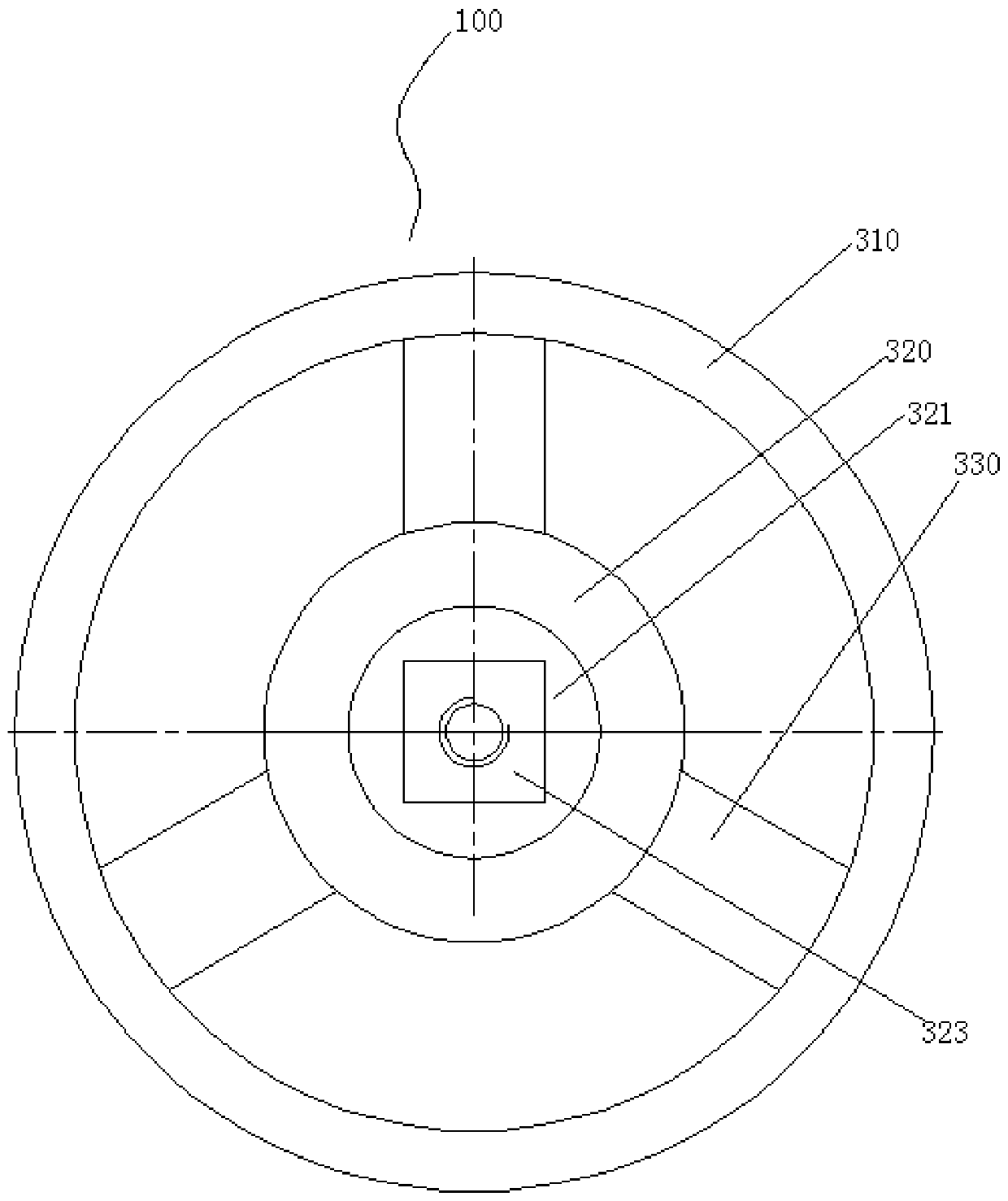

[0020] Such as Figure 1 to Figure 3 As shown, a transmission belt forming mold that can be reversibly installed repeatedly includes an upper cover 100, a base 200, a ring mold 400, and a fastening device 600. The upper cover 100 and the base 200 have the same or different structures, but they can be used interchangeably. , the ring die 400 is set between the base 200 and the upper cover 100, at least two ring dies 400 are arranged between the base 200 and the upper cover 100, each ring die is provided with a molding surface, after the upper and lower ring dies are stacked , the molding surfaces of the upper and lower ring molds form at least one mold cavity 500 for installing the transmission belt, the upper cover 100 and the base 200 are fixedly connected by the fastening device 600 and the ring mold 400 is fixed between the upper cover 100 and the base 200 .

[0021] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com