Tube mould for continuous casting

An ingot mold and continuous casting technology, which is applied in the field of tubular ingot molds, achieves the effects of high processing speed, increased output, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

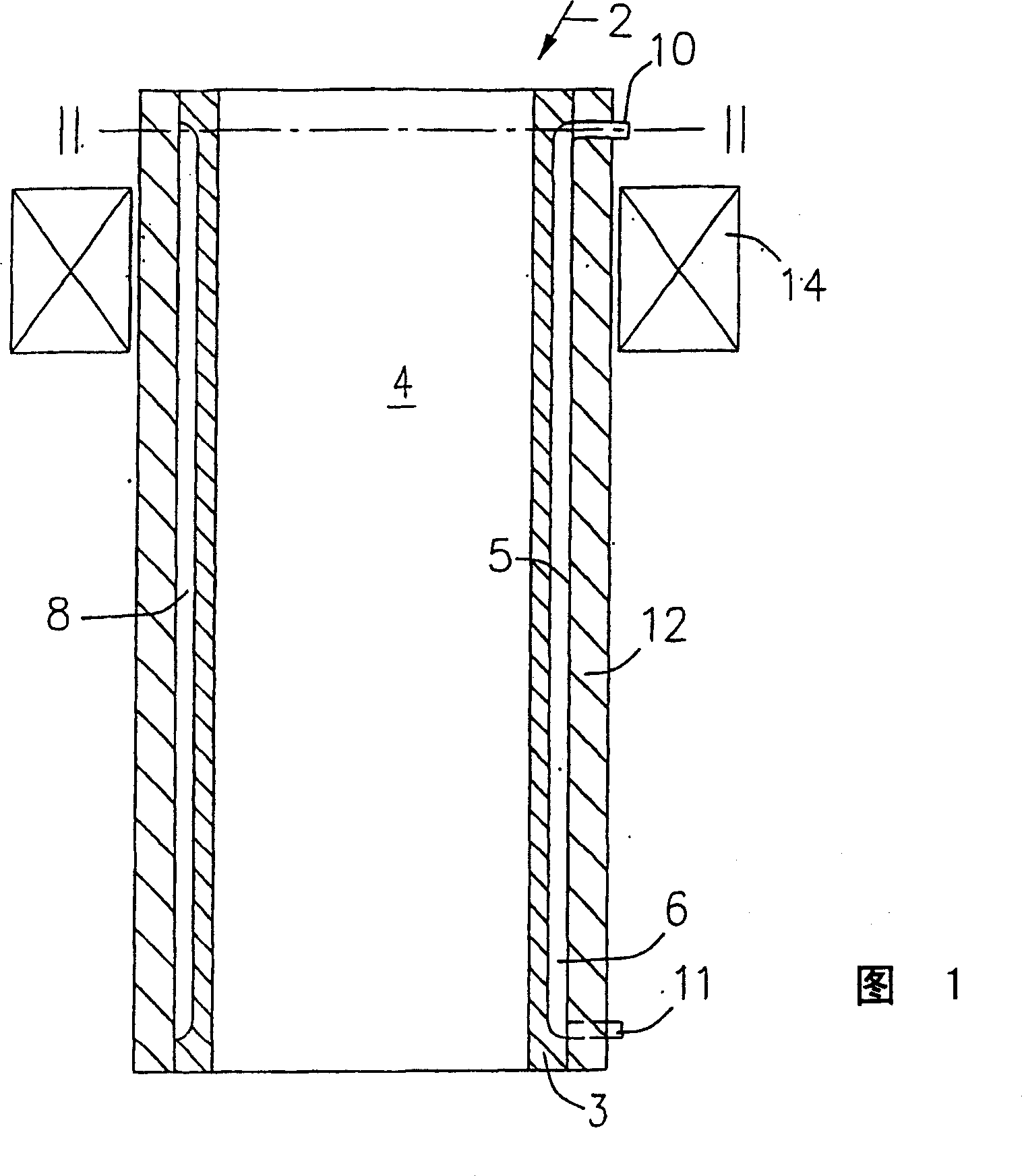

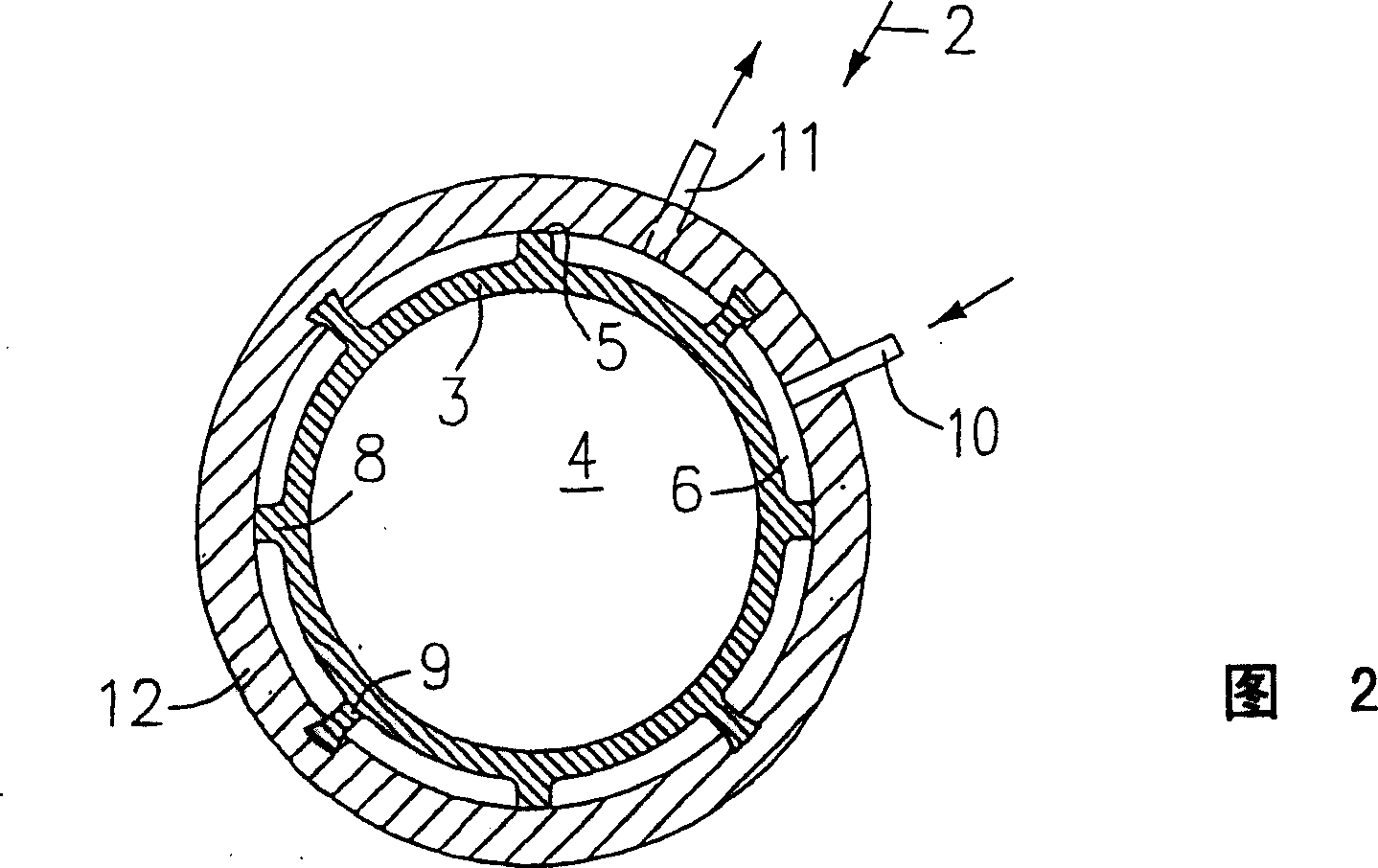

[0028] In FIGS. 1 and 2 , a continuous casting mold for round billets or blooms is indicated by 2 . A copper tube 3 forms a cavity 4 . A water circulation cooling system for the copper tube 3 is arranged outside the copper tube 3 forming the tube outer side 5 . This water circulation cooling system consists of cooling channels 6 distributed over the entire circumference and essentially the entire length of the copper tube 3 . The individual cooling channels 6 are delimited by supporting and connecting flanges 8 and 9, the other task of which is to guide the cooling water circulation in the cooling channel 6 from a water supply pipe 10 into a The drainage pipes 11 and 12 designate a support shell which surrounds the copper tube 3 over its entire circumference and over its entire length and which supports the copper tube 3 on the outer side 5 of the tube via a support flange 8 . The connection flange 9 connects the copper pipe 3 to the support shell 12 . The support shell 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com