A thermally transferred graphene antenna and its preparation method and application

A graphene and thermal transfer printing technology, applied in antennas, resonant antennas, antenna parts, etc., can solve the problems that three-dimensional objects cannot be conformal, graphene antennas can only be printed on flat substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

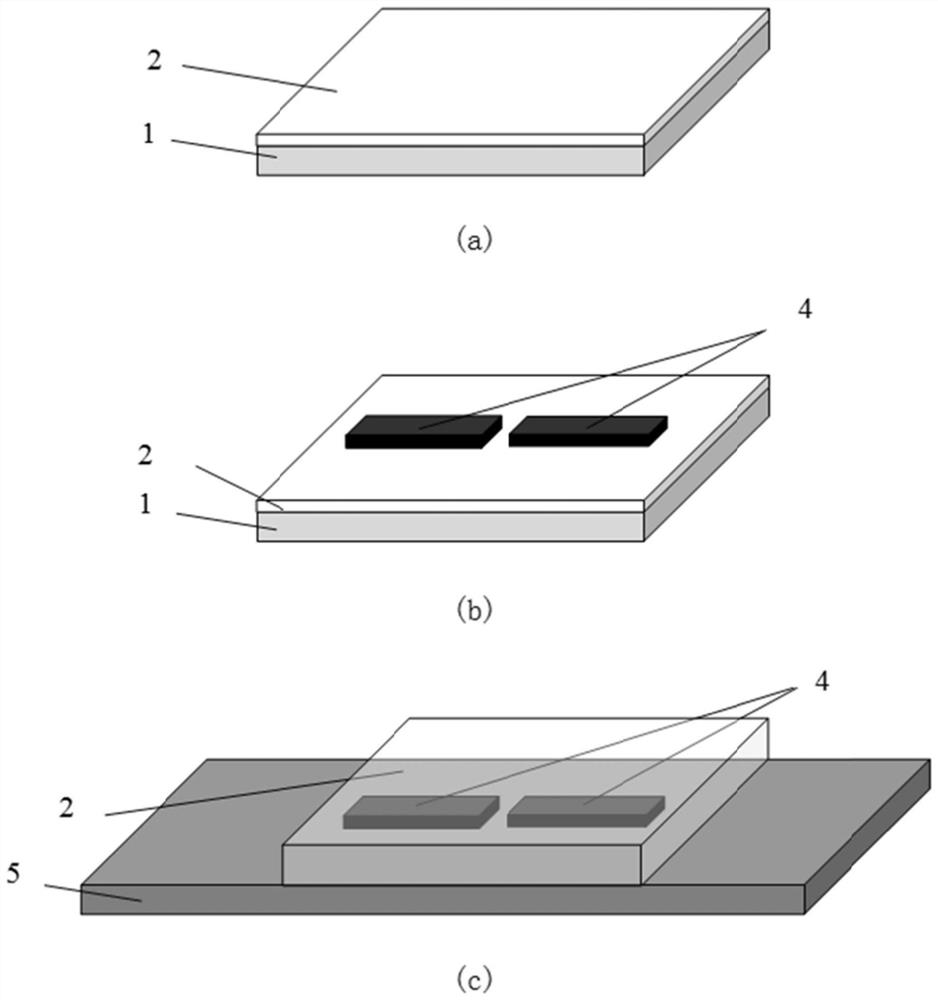

[0040] The pattern of the graphene antenna is a graphene printing layer, and the graphene printing layer is transferred to the target substrate together with the thermal transfer film. The specific steps include:

[0041] Step 01: Print the graphene conductive ink on the thermal transfer paper by screen printing to form a graphene printing layer, the printing speed is 5-100 mm / s, and the graphene printing layer is in the shape of the designed antenna ;

[0042] Step 02: Use thermal curing to dry and cure the graphene printing layer, the curing temperature is 50-120°C, and the time is 10-120 minutes;

[0043] Step 03: Thermally transfer the structure obtained in Step 02 at a temperature of 150-300°C for 1-10 minutes, so that the graphene printing layer is detached from the thermal transfer paper substrate and transferred to the target substrate.

[0044] In this embodiment, the printing technology of screen printing is adopted to prepare the graphene printing layer, but it is ...

Embodiment 2

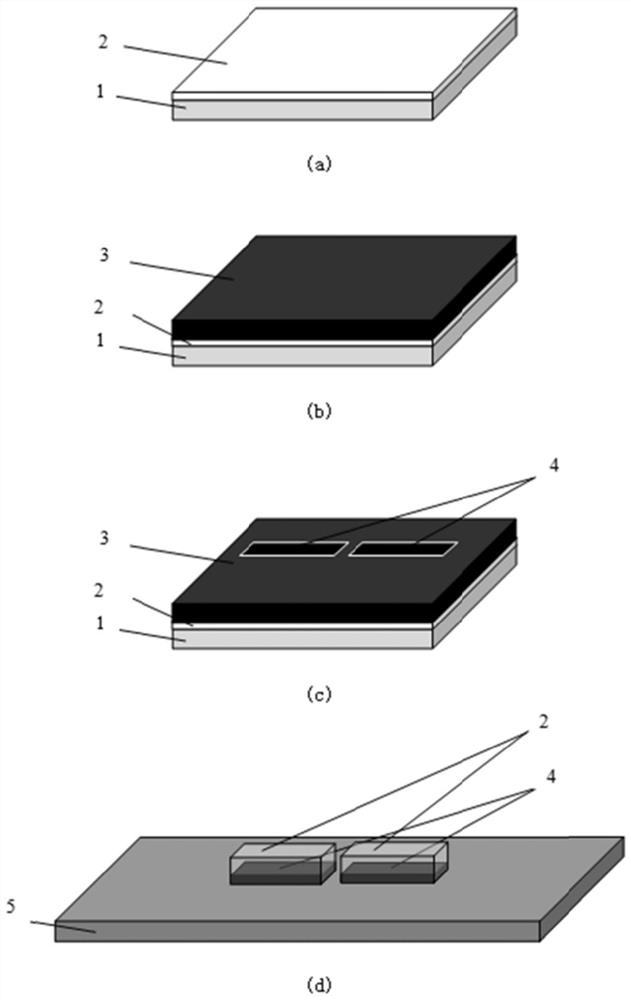

[0050]The pattern of the graphene antenna is formed by micro-nano processing of the graphene printing layer by micro-nano processing technology, and the patterned graphene printing layer is transferred to the substrate together with the thermal transfer film, which specifically includes the following steps:

[0051] Step 01: Print the graphene conductive ink on the thermal transfer paper by scraping to form a graphene printing layer, and the printing speed is 5-100 mm / s;

[0052] Step 02: Dry and solidify the graphene printing layer by thermal curing, the curing temperature is 50-120 degrees Celsius, and the curing time is 10-120 minutes;

[0053] Step 03: Use laser engraving technology to pattern the graphene printing layer, and etch out the designed antenna pattern;

[0054] Step 04: Thermally transfer the structure obtained in step 03 at a temperature of 150-300°C for 1-10 minutes, so that the graphene printing layer is detached from the thermal transfer paper substrate and...

Embodiment 3

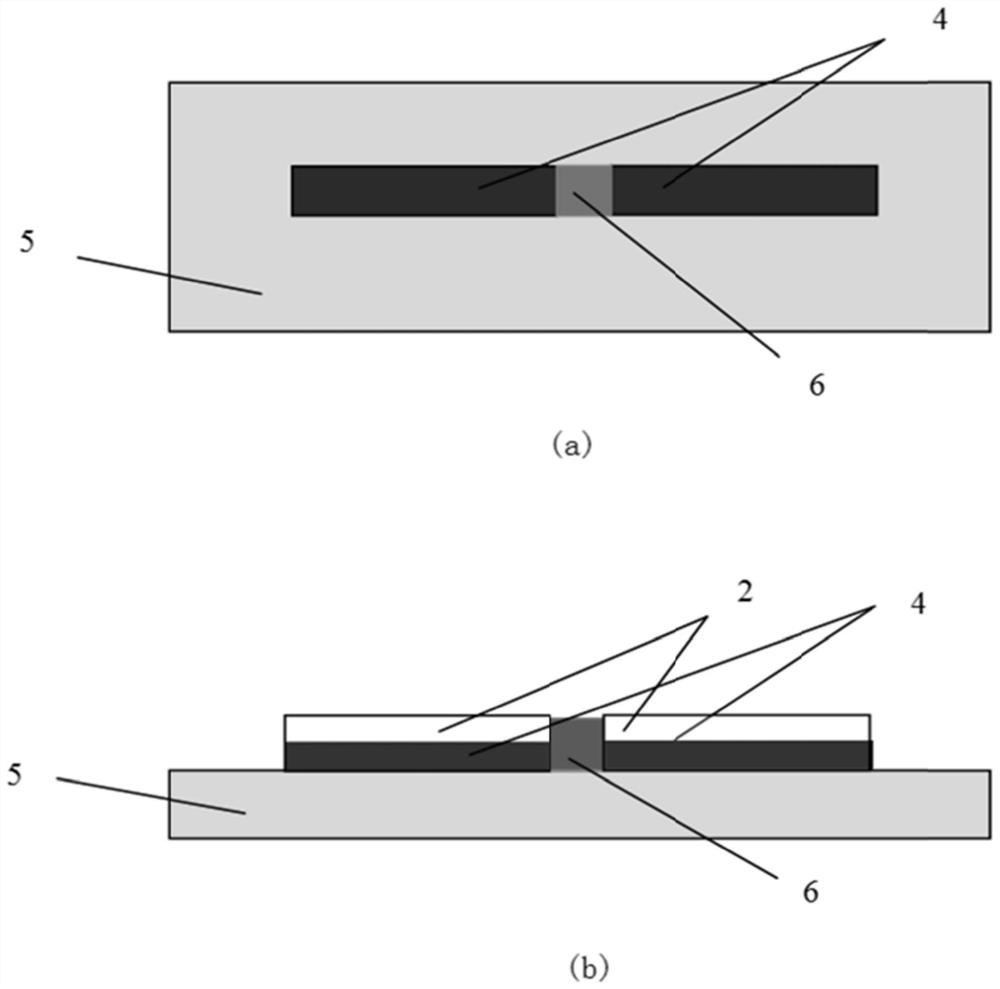

[0061] The prepared graphene antenna is connected to the RFID chip through conductive silver paste to form an RFID tag based on the printed graphene antenna. Among them, the RFID chip can be purchased from the market or designed and manufactured by itself according to the actual scene requirements.

[0062] Such as image 3 As shown, the graphene antenna-based RFID tag prepared by the present invention consists of a graphene antenna 4 and an RFID chip 6 in two parts.

[0063] Embodiment 3 uses conductive silver paste to connect graphene antenna 4 with RFID chip 6, but also can use other conductive adhesives, comprise metal conductive adhesive and non-metallic conductive adhesive; RFID chip 6 can not be placed on even Between the two arms of the pole antenna, but the pins of the chip must be electrically connected to the antenna to form a conductive path. Using micro-nano processing technology, if the size is appropriate, the RFID chip 6 can be placed directly between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com