Airtight valve air tightness detection equipment

An air tightness detection and sealing valve technology, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, measuring device, etc., which can solve the inconvenience of removing the support rod 8, and placing and removing it repeatedly. The support rod process is cumbersome and other problems, to achieve the effect of simplifying the detection process and avoiding the offset in the vertical direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

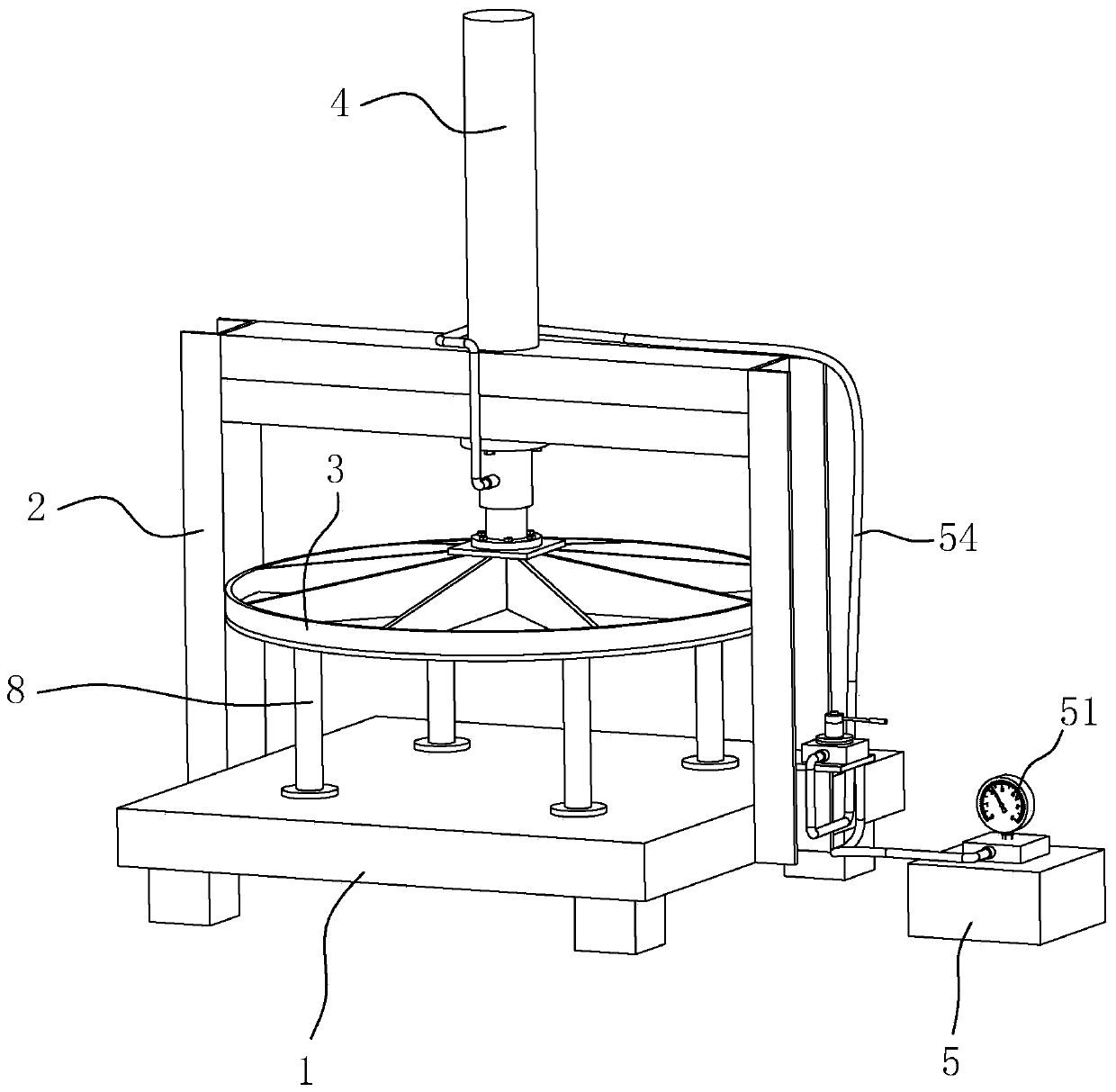

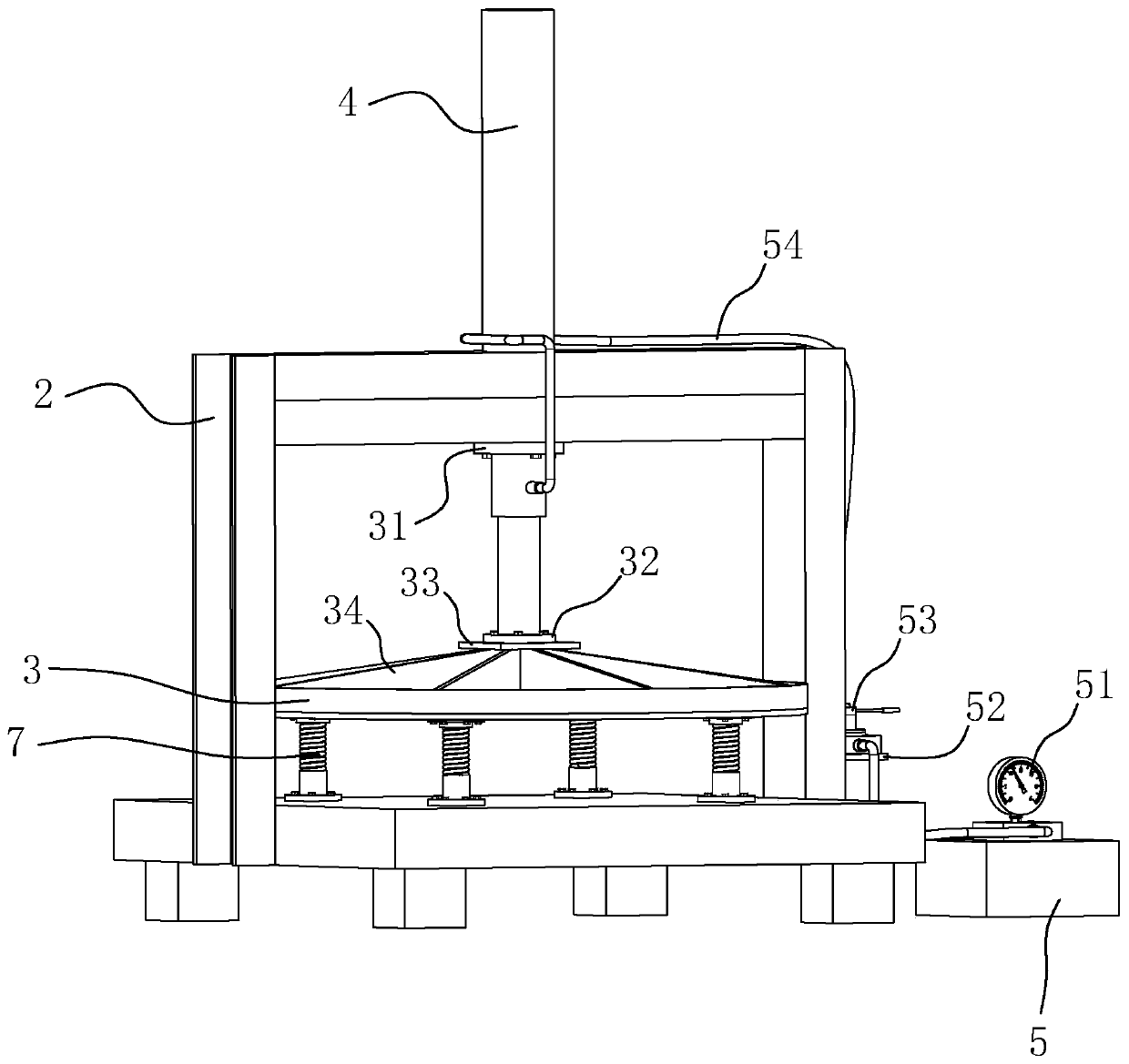

[0041] Embodiment one: refer to image 3 , is an airtightness testing device for a closed valve disclosed in the present invention, comprising a base 1 with a horizontal upper surface, a mounting frame 2 is welded on the base 1, a cylinder 4 is installed at the center of the mounting frame 2, and the piston rod of the cylinder 4 faces The bottom is set, the cylinder body of the cylinder 4 passes through the mounting frame 2, and its lower end is connected and fixed with the bottom bolt of the mounting frame 2 through the flange 31.

[0042] The lower end of the cylinder 4 piston rod is welded with a disc 32, the disc 32 is fixed with a square connecting plate 33 by bolts, the lower surface of the connecting plate 33 is fixed with a pressure plate 3, and the upper surface of the pressure plate 3 is welded with a vertical rib 34, the rib The plates 34 are distributed in a circular array with respect to the center of the pressure plate 3 , and the tops of the ribs 34 are welded t...

Embodiment 2

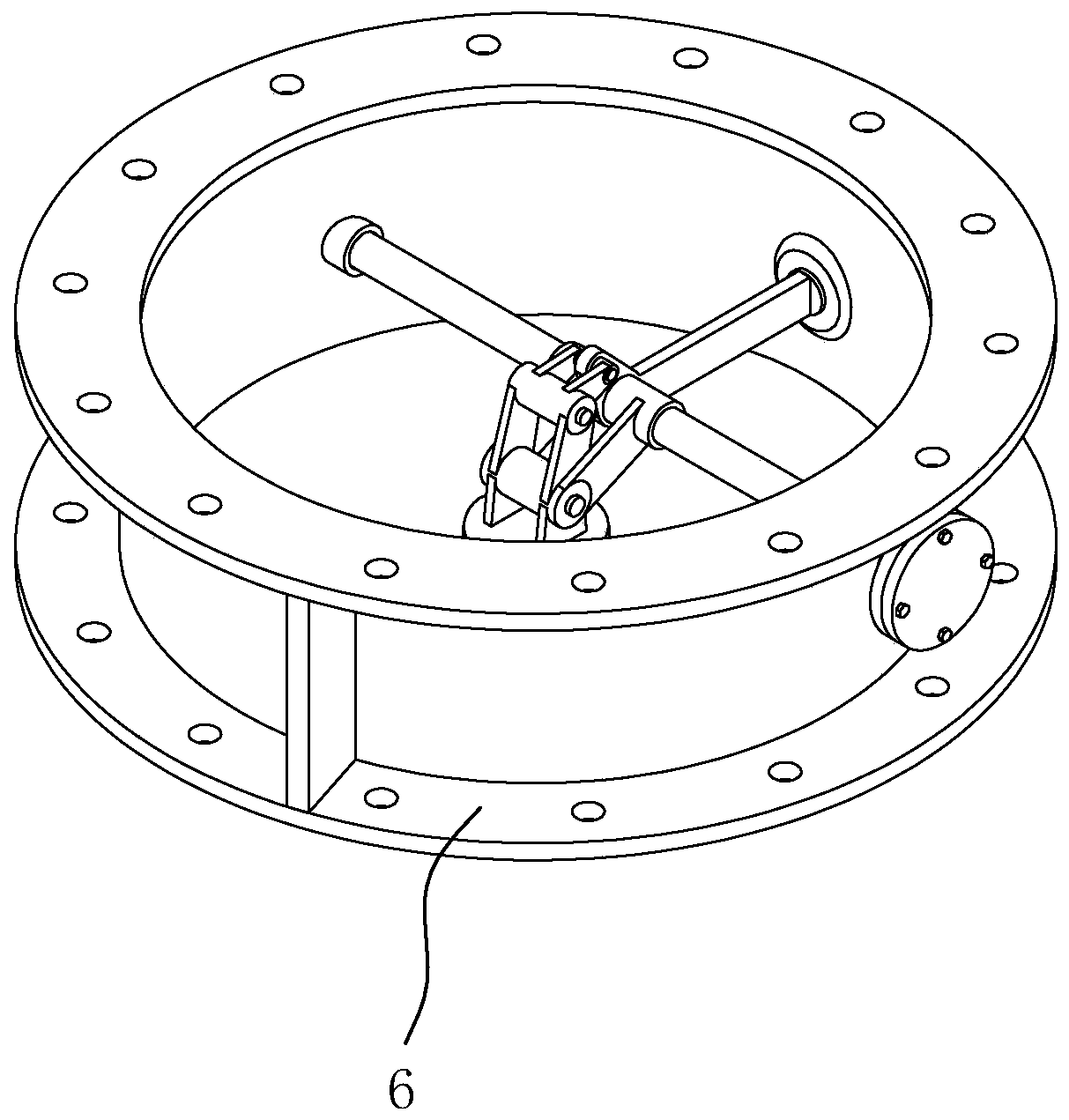

[0051] Embodiment 2: an airtightness detection device for a closed valve, which is different from Embodiment 1 in that, such as Figure 5 As shown, the interior of the support cylinder 71 in the support assembly 7 is hollow and a sliding cylinder 75 is slidably connected, as shown in Image 6 and Figure 7 As shown, the inner wall of the support cylinder 71 is provided with an axial sliding groove 751, and the outer wall of the sliding cylinder 75 is provided with a sliding block 752, which slides in the sliding groove 751 by sliding. The upper end of the sliding cylinder 75 is fixed with the base 1 by bolts, the lower end is welded with a spring 73, and the lower end of the spring 73 is welded and fixed with the bottom of the inner wall of the support cylinder 71. is compressed; when the pressure plate 3 rises after testing the airtight valve 6, the spring 73 recovers upwards, but is still in a slightly pressurized state, thereby providing an upward support force to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com