Electric connector

A technology for electrical connectors and joints, applied in the field of electrical connectors, can solve problems such as unformed specifications, and achieve the effects of reducing electrical length, reducing wavelength, and increasing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

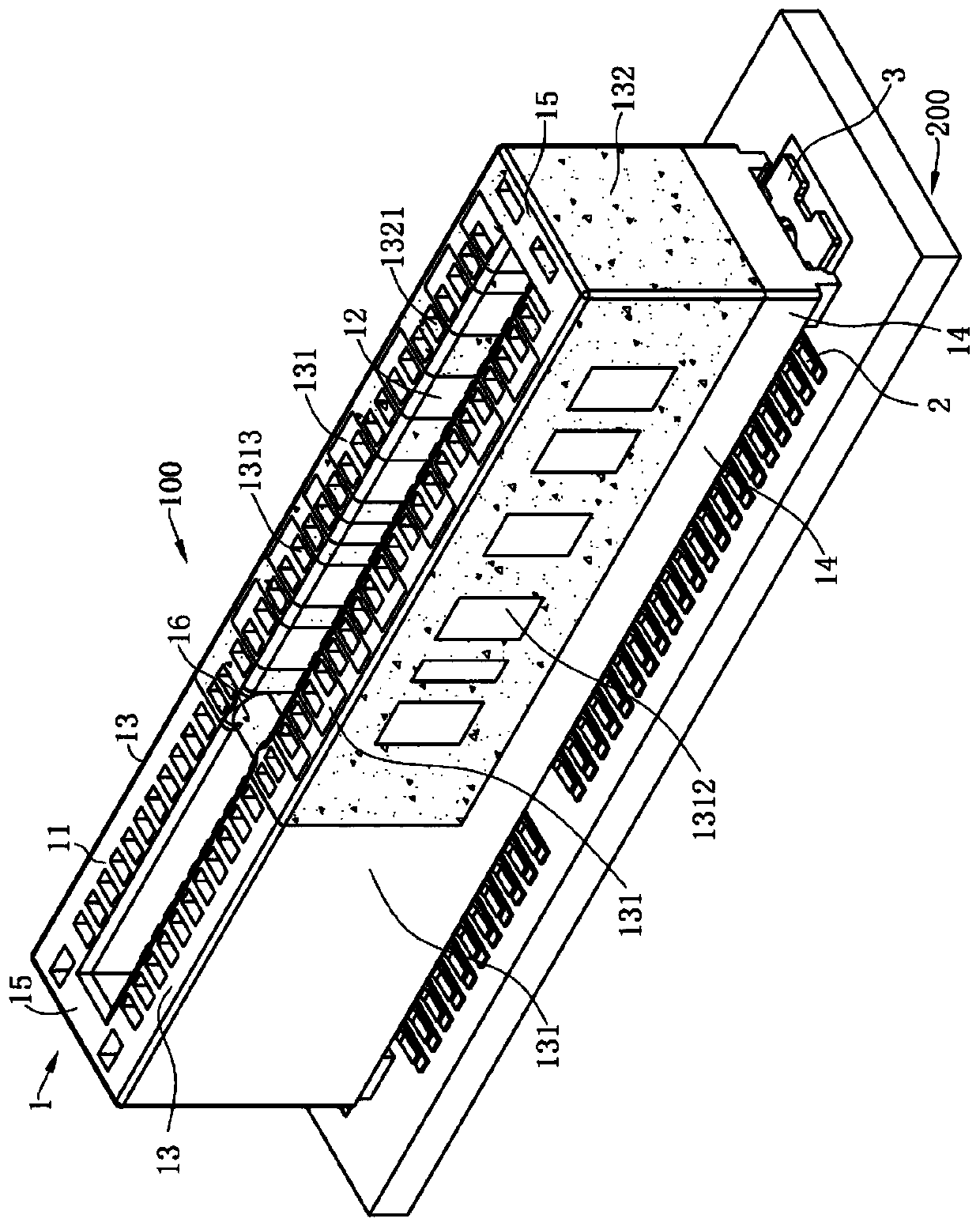

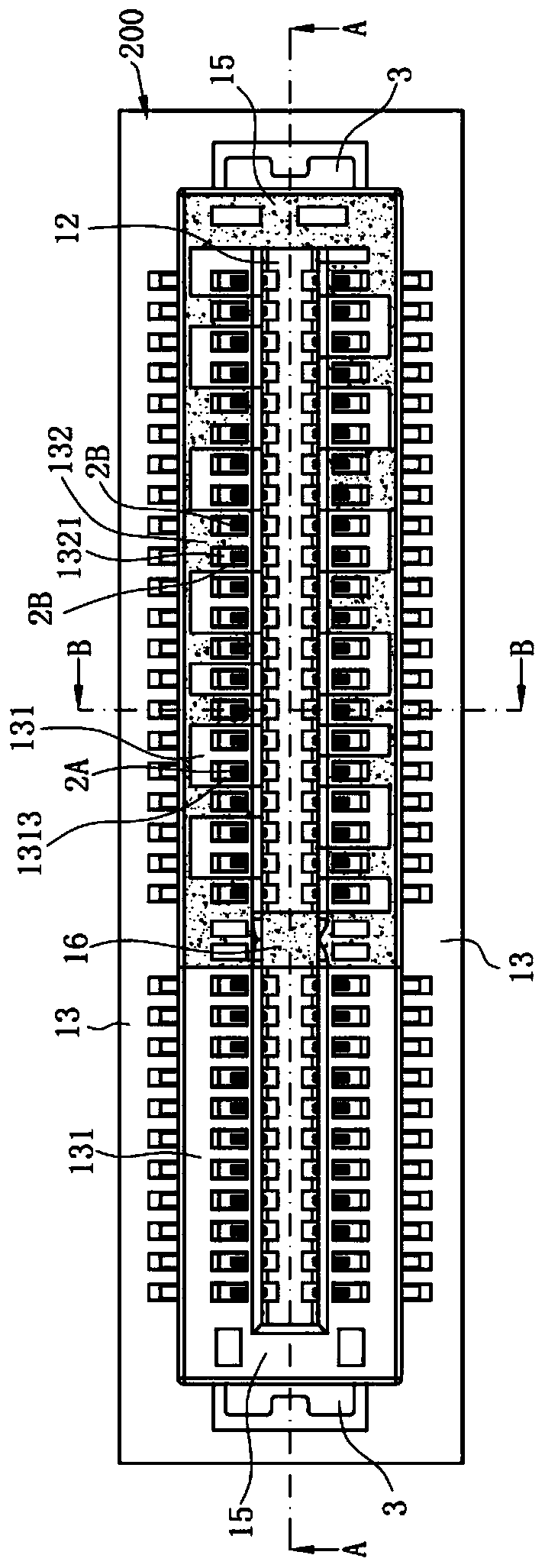

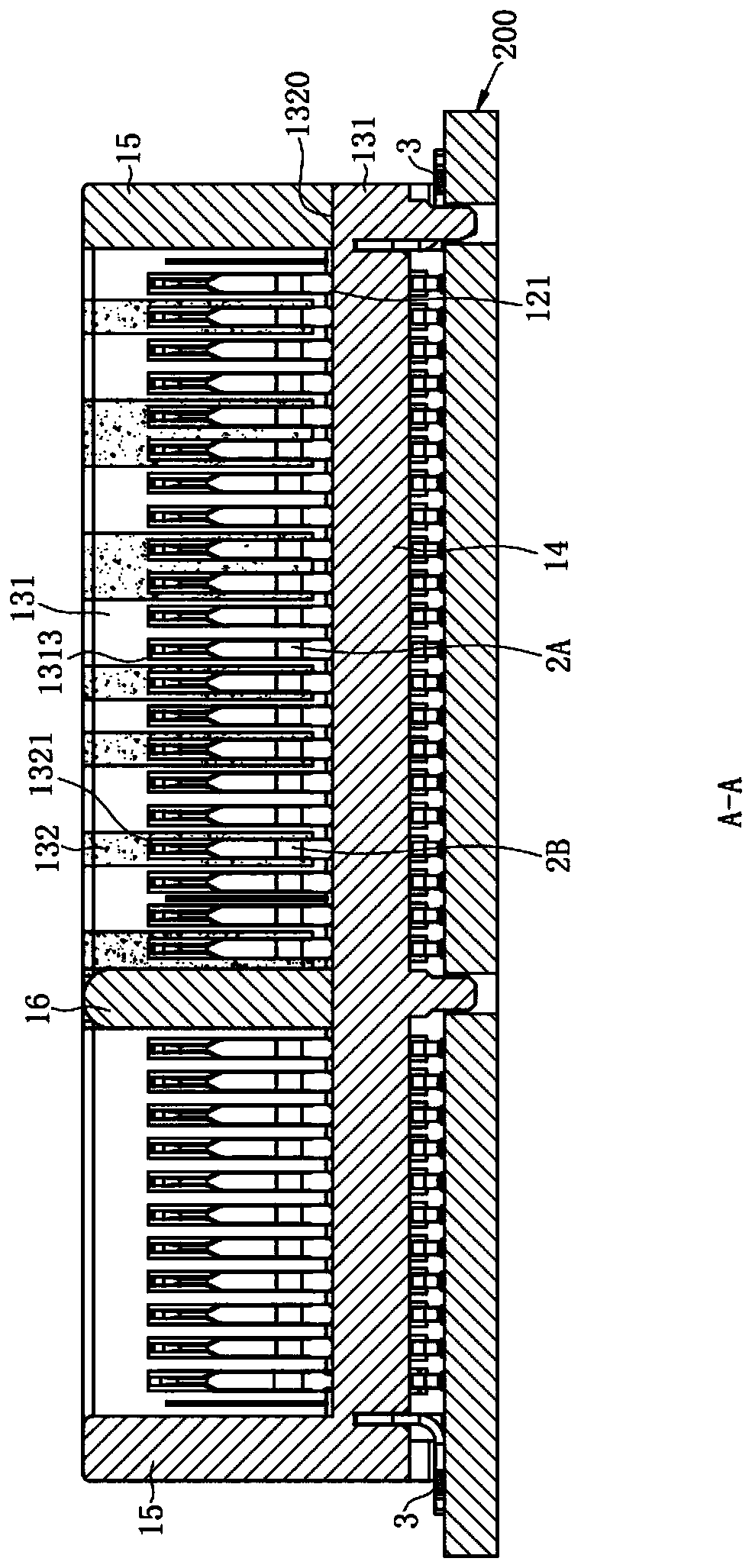

[0053] Such as figure 1 and figure 2 As shown, it is a preferred embodiment of the electrical connector 100 of the present invention, the electrical connector 100 is installed on a circuit board 200, and is used to insert a mating element (not shown), for example, the mating element for electronic cards. The electrical connector 100 includes a body 1 and a plurality of conductive terminals 2 mounted on the body 1, the body 1 is made of insulating plastic and conductive plastic, and the plurality of conductive terminals 2 include a plurality of signal terminals 2A As well as the plurality of ground terminals 2B, the structure and size of the signal terminal 2A and the ground terminal 2B are the same.

[0054] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com