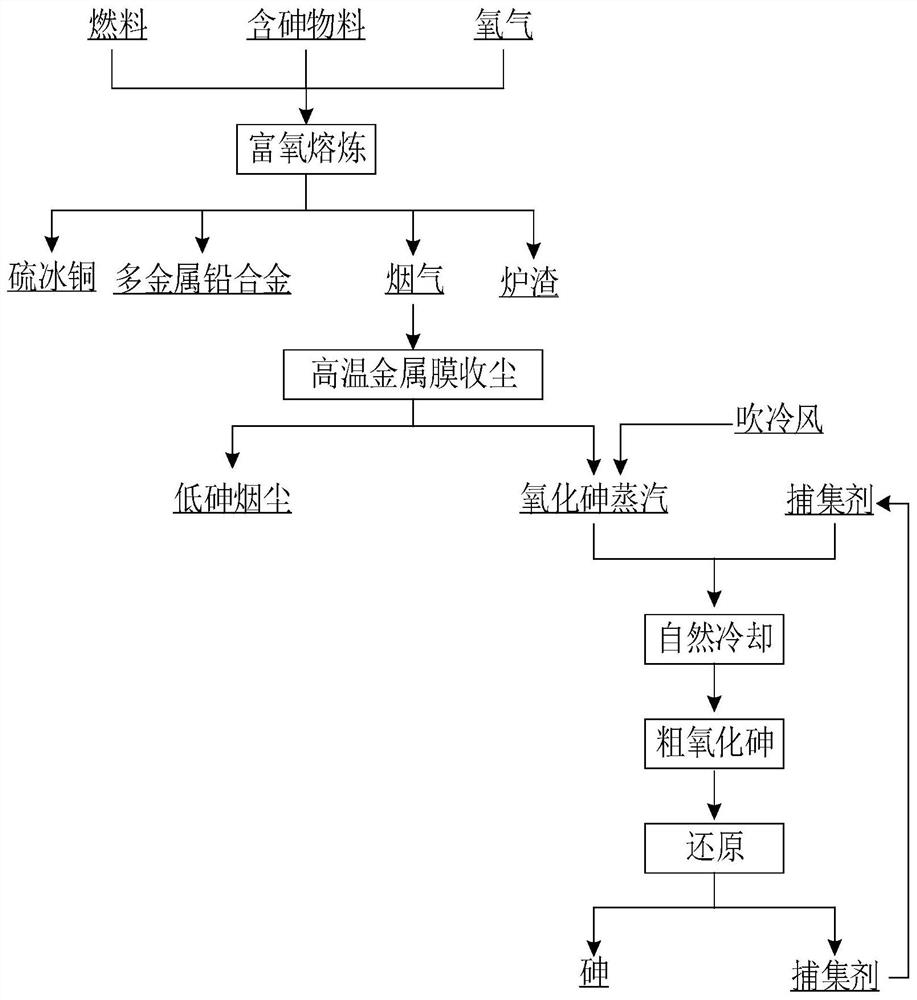

A method and system for recovering arsenic from arsenic-containing flue gas

A technology for recovering arsenic and flue gas, applied in the field of arsenic recovery, can solve the problems of easy paralysis of the system and blockage of equipment by glass arsenic, and achieve the effects of saving expenses, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

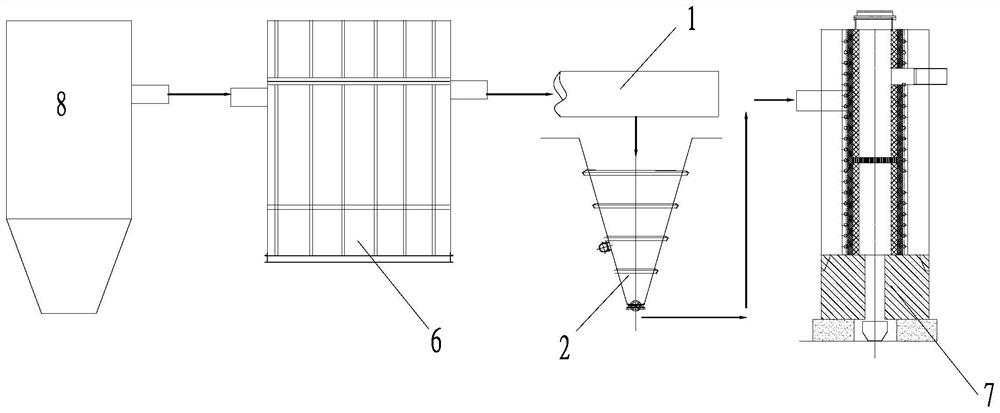

Method used

Image

Examples

Embodiment 1

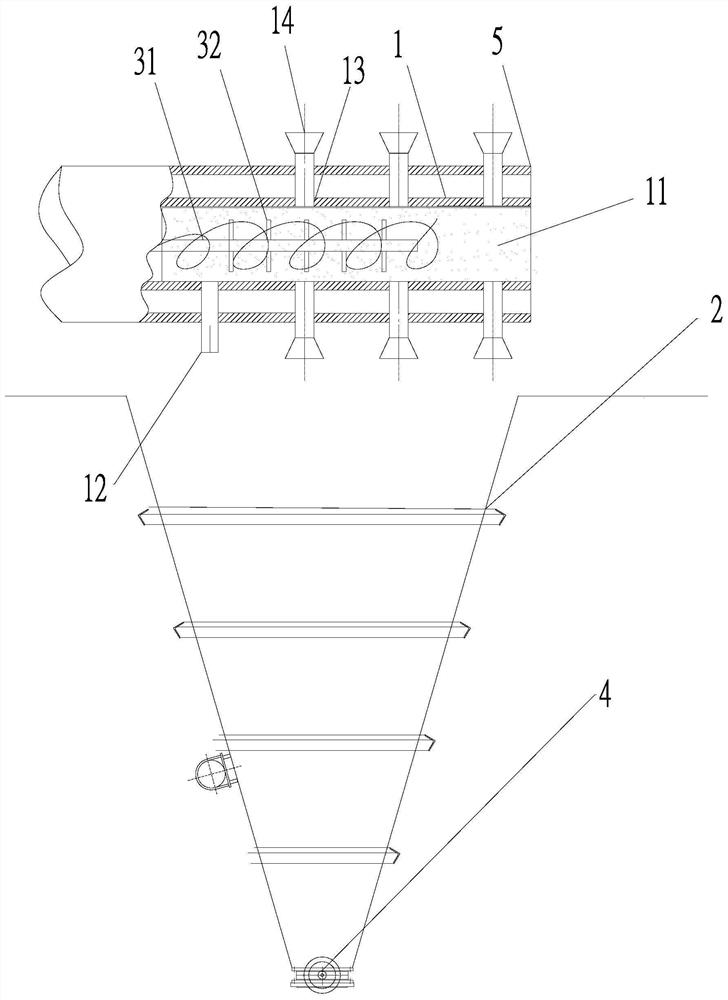

[0072] Arsenic steam by metal filter film: temperature 450 ° C, arsenic 100g / m 3 After entering the trap 1, blow into the cold air, drop the steam temperature to a 40% of the cavity of 5 mm, while blowing a particle size of 5 mm (charcoal powder and calcium oxide, mass ratio 2: 3) accounts for 25% of the quality of the oxide quality. After the natural surface cooler, through the bag is dust, it is 78.9%, carbon 7.84% carbon, 11.64% calcium oxide, and other 1.62% of the smoke, bag, pipe and the tubular and the tandem without oxidation arsenic glass, system normal. The smoke after the collection was reduced in vacuo (temperature 800 ° C, vacuum 20 Pa, and the time was 90min) to give metal arsenic.

Embodiment 2

[0074] Arsenic steam by metal filter film: temperature 450 ° C, arsenic 120g / m 3 After entering the trap 1, blow into the cold air, falling to the flue gas temperature to 350 ° C, and the particle size of 5 mm is blown (charcoal and calcium oxide, mass ratio 2: 4) accounts for 30% of the quality of the oxide quality. After the natural surface cooler, through the bag is dust-containing, 76.2%, carbon 9.12%, carbon oxide, 13.53%, other 1.15% soot, pipe, pipe and refrigerator do not produce oxide glass, the system is normal . Metal arsenic was obtained by vacuum reduction (temperature 900 ° C, vacuum 10 Pa, time length 60min).

Embodiment 3

[0076] Oxidative steam of metal filter film: temperature 450 ° C, arsenic 150g / m 3 After entering the trap 1, blow into the cold wind, falling to the flue gas temperature to 350 ° C, and the blowing agent (reduction pulverized coal and magnesium oxide, mass ratio 2: 3) in the air blowing particle size is 5 mm. 40%, after the natural surface cooler, through the bag is dust-filled, 70.88%, carbon 10.52% carbon, magnesium oxide, and other 2.35% smoke, bag, pipe and the chiller do not produce oxide glass, The system is normal. The smoke after the collection was reduced in vacuo (temperature 850 ° C, vacuum 15 Pa, and 50 min) obtained metal arsenic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com