Solid-liquid two-phase hydraulic design method used for deep-sea mining mine lifting pump

A technology for hydraulic design and deep-sea mining, which is applied to the components of pumping devices for elastic fluids, mining minerals, and special mining, etc., and can solve the problems of easy blockage, poor wear resistance, and low solid-liquid conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

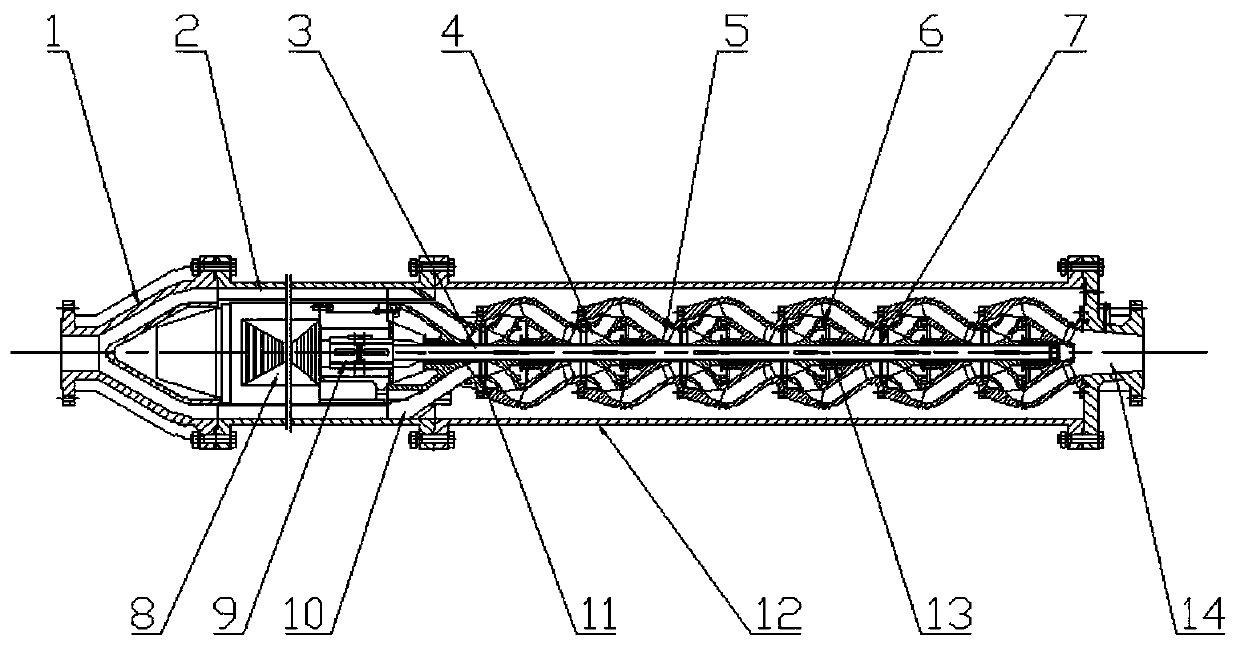

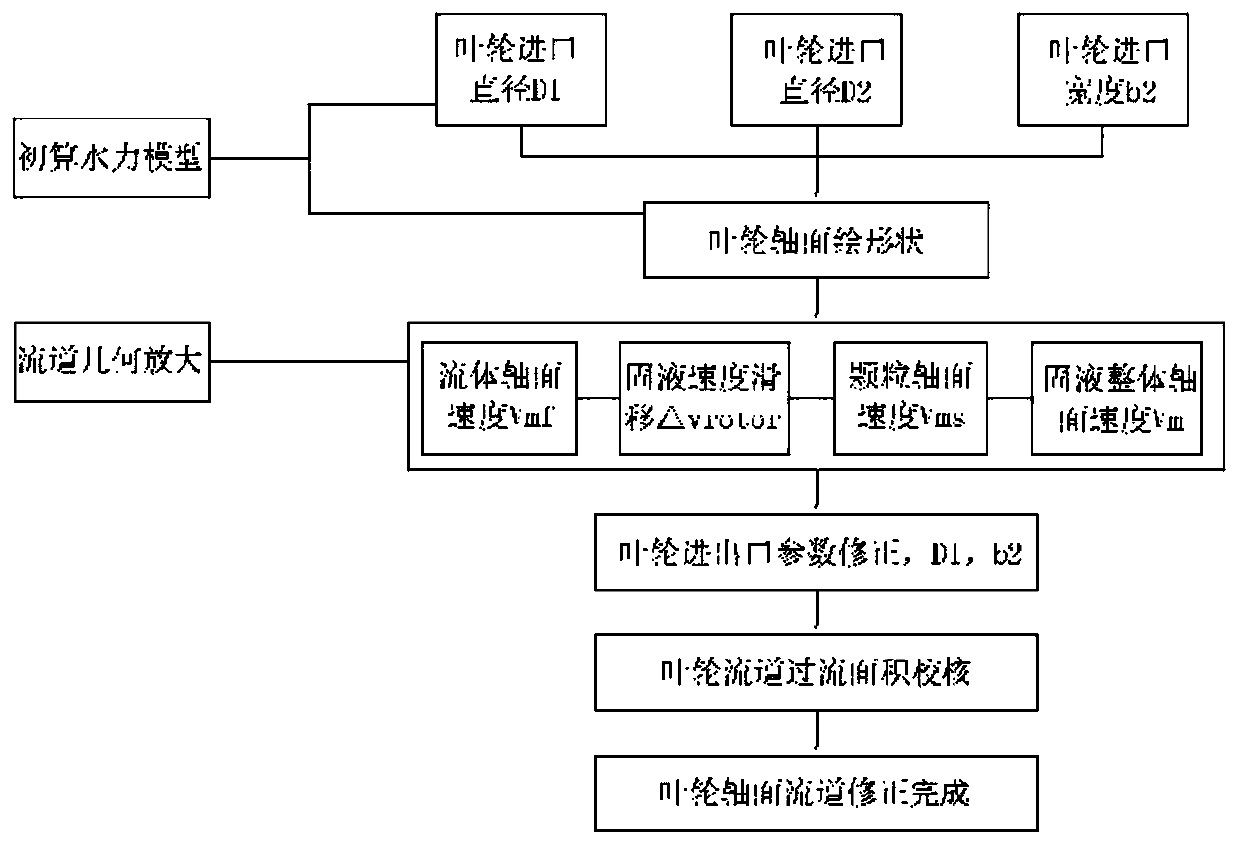

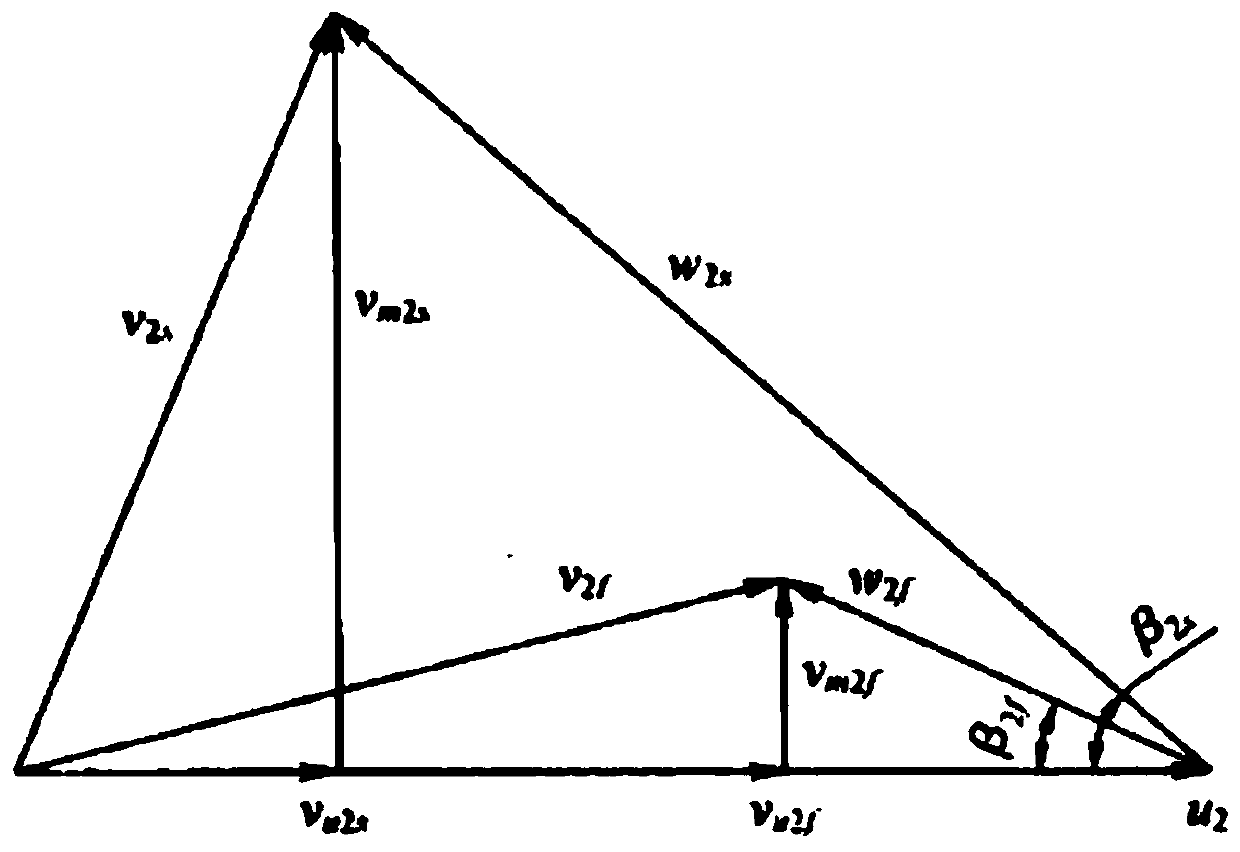

[0053] Example: such as Figure 1-10 As shown, a solid-liquid two-phase hydraulic design method for deep-sea mining pumps, the solid-liquid slurry drives the multi-stage long-axis rotor 3 through the wet submersible motor 8 to drive the six rotating impellers on the multi-stage long-axis rotor 3 The stationary guide vane body 5 in 4 enters the annular flow channel 2 inside the outer cylinder 12 from the inlet section 1, and drives the main shaft 3 to drive the sand discharge tray 7 in the rotating impeller 4 to avoid mortar silting during solid-liquid slurry transportation The channel affects the drainage efficiency. Then pass through the suction section 10 under the pressure of the rotation of the guide vane 5, and finally discharge from the discharge section 14, through the connection between the suction section 10 and the rotating impeller 4, the impeller sealing ring 11, the rotating impeller 4 and the stationary guide vane body 5 The front end is provided with a pump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com