Bolt looseness main influence parameter evaluation and looseness relieving method under vibration working condition

A technology that affects parameters and relaxation. It is used in vibration testing, screws, threaded fasteners, etc. It can solve the problem that the parameters affecting bolt relaxation cannot be evaluated, and achieve the effect of solving many tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

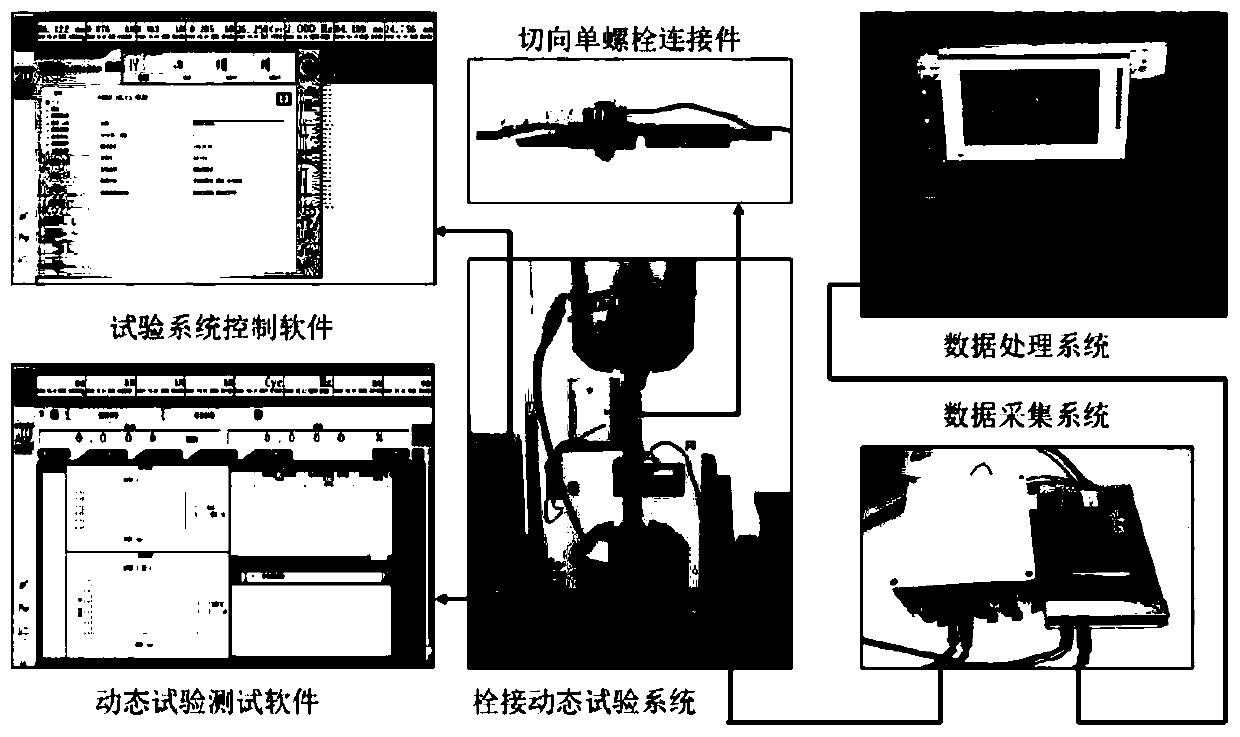

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific examples. It should be understood that these implementations are only for illustrating the present invention and do not limit the scope of the present invention. Unless otherwise specified, the test pieces, methods and equipment used in the present invention are commonly used test pieces, methods and equipment in this technical field.

[0024] 1. Selection of parameters affecting bolt relaxation under vibration conditions

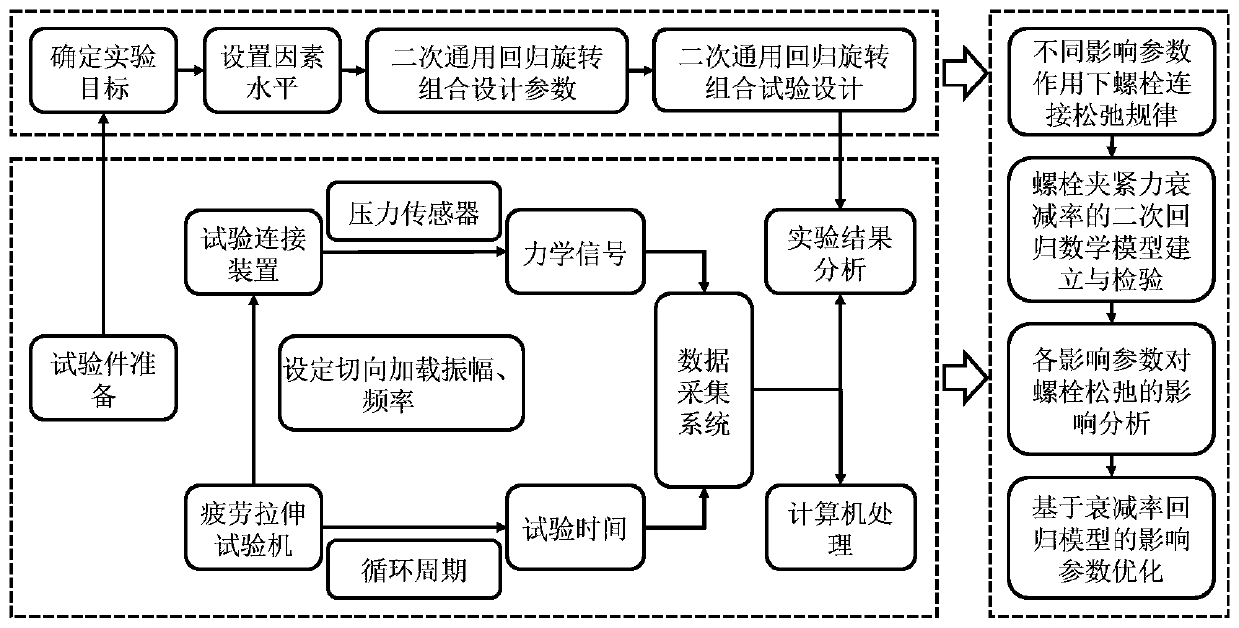

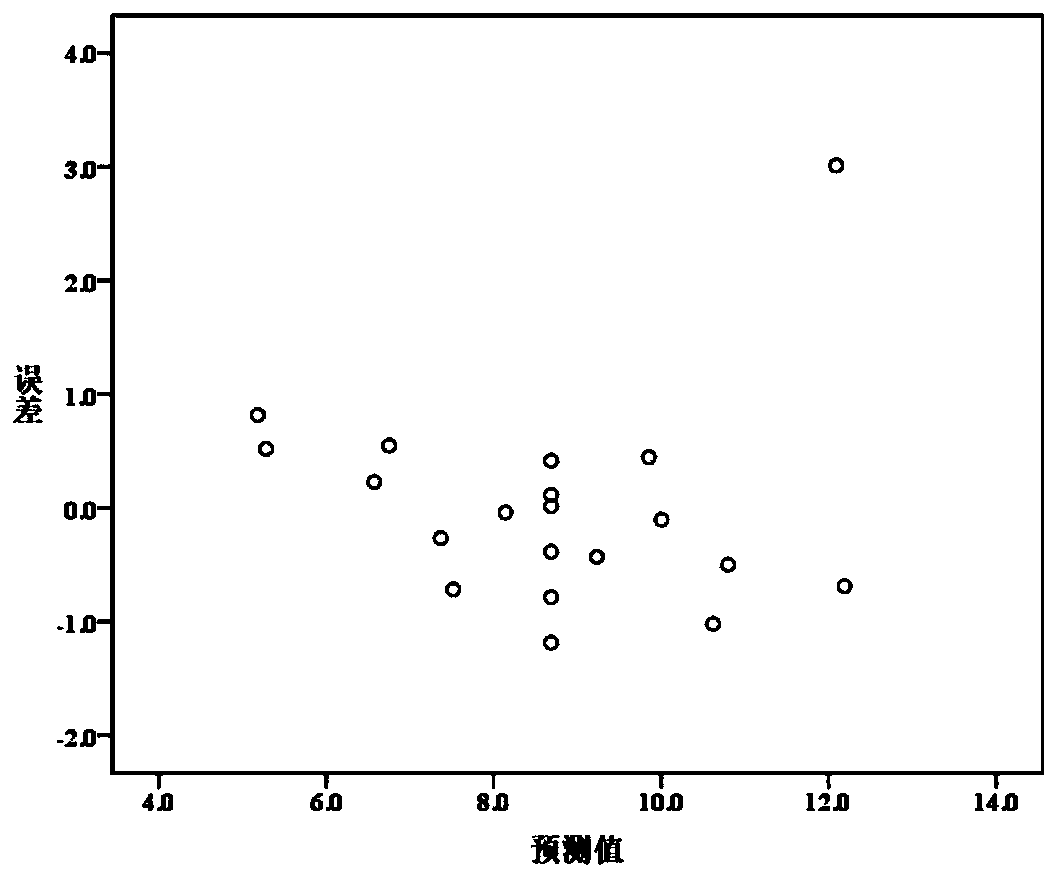

[0025] The load amplitude, vibration frequency, and initial tightening torque that affect the bolt clamping force are three test factors, and the attenuation rate of the bolt clamping force is the target, and a secondary general rotation combination design of three factors and five levels is made, a total of 20 Combination of experimental values, used to determine the best combination of three experimental factors.

[0026] 2. Range det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com