A device for measuring strain rate during explosive impact

A measuring device and strain rate technology, applied in the field of explosive performance parameter experiments, can solve the problems of measuring strain rate, poor visibility of impact process, and no test method for kilogram explosive samples, and achieve the effect of strong acceleration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a strain rate measuring device for the impact process of explosives is designed to measure the impact strain rate of 9 g of explosives at a speed of 150 m / s.

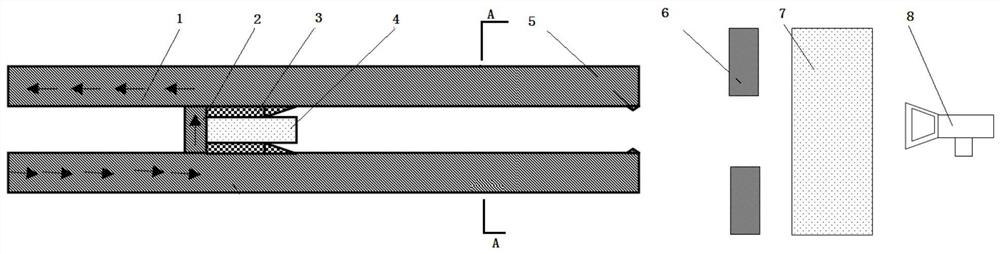

[0030] Choose Light Gas Cannon to give Dynamite 4 speed.

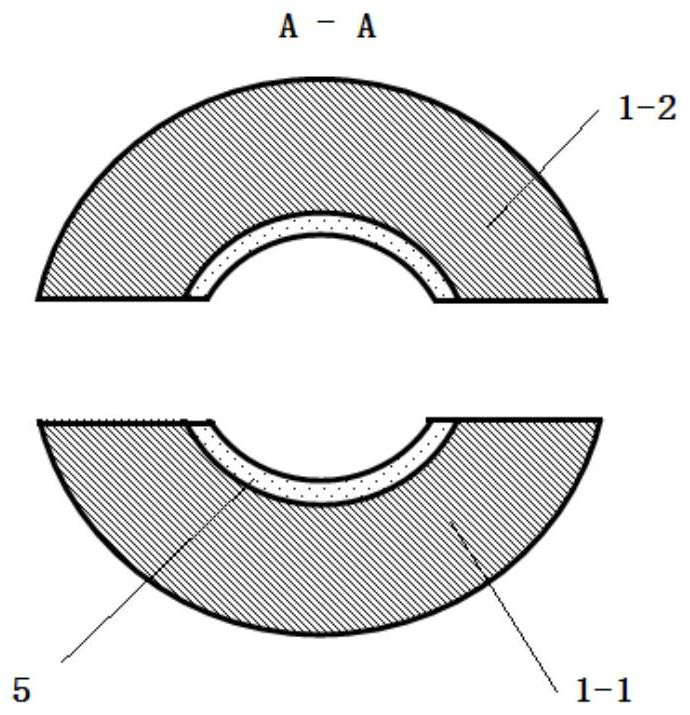

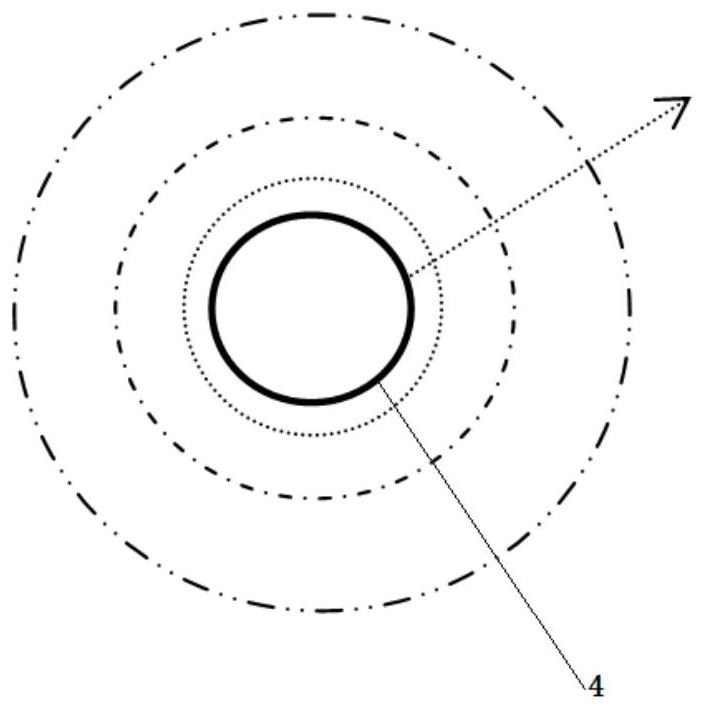

[0031] A device for measuring strain rate during explosive impact, said device comprising guide rail 1, slider 2, housing 3, explosive 4, turning tool 5, speed measuring target 6, target plate 7 and high-speed photography 8, said explosive impact process The components of the strain rate measuring device are installed sequentially along the same axis. The guide rail 1 is a conductive metal, and the cross section of the guide rail 1 is a circular ring with a notch. , the track A1-1 and the track B1-2 are overall long rods with equal cross-sections, the cross-sections of the track A1-1 and the track B1-2 are fan-shaped at an angle of 180°, and the track A1-1 and the track B1- 2 Symmetrical installation, the middle of the track A1-1 and ...

Embodiment 2

[0040] In this embodiment, a device for measuring strain rate during explosive impact is designed to measure the impact strain rate of 1000 g of explosive at a speed of 100 m / s.

[0041] Accelerate Dynamite 4 with the Electromagnetic Railgun.

[0042] A device and method for measuring strain rate during explosive impact, said device comprising guide rail 1, slider 2, housing 3, explosive 4, turning tool 5, speed measuring target 6, target plate 7 and high-speed photography 8, said explosive The components of the strain rate measurement device during the impact process are installed sequentially along the same axis. The guide rail 1 is a conductive metal, and the cross section of the guide rail 1 is a circular ring with a gap. The guide rail 1 is composed of a positive pole track 1-1 and a negative pole track 1-2, the positive pole track 1-1 and the negative pole track 1-2 are long rods with equal cross-section as a whole, and the cross-sections of the positive pole track 1-1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com