LED ceiling lamp with built-in driving power supply

A LED chandelier and drive power technology, applied in the direction of electric light source, circuit layout, with built-in power supply, etc., can solve the problems of heat accumulation and heat inability to dissipate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

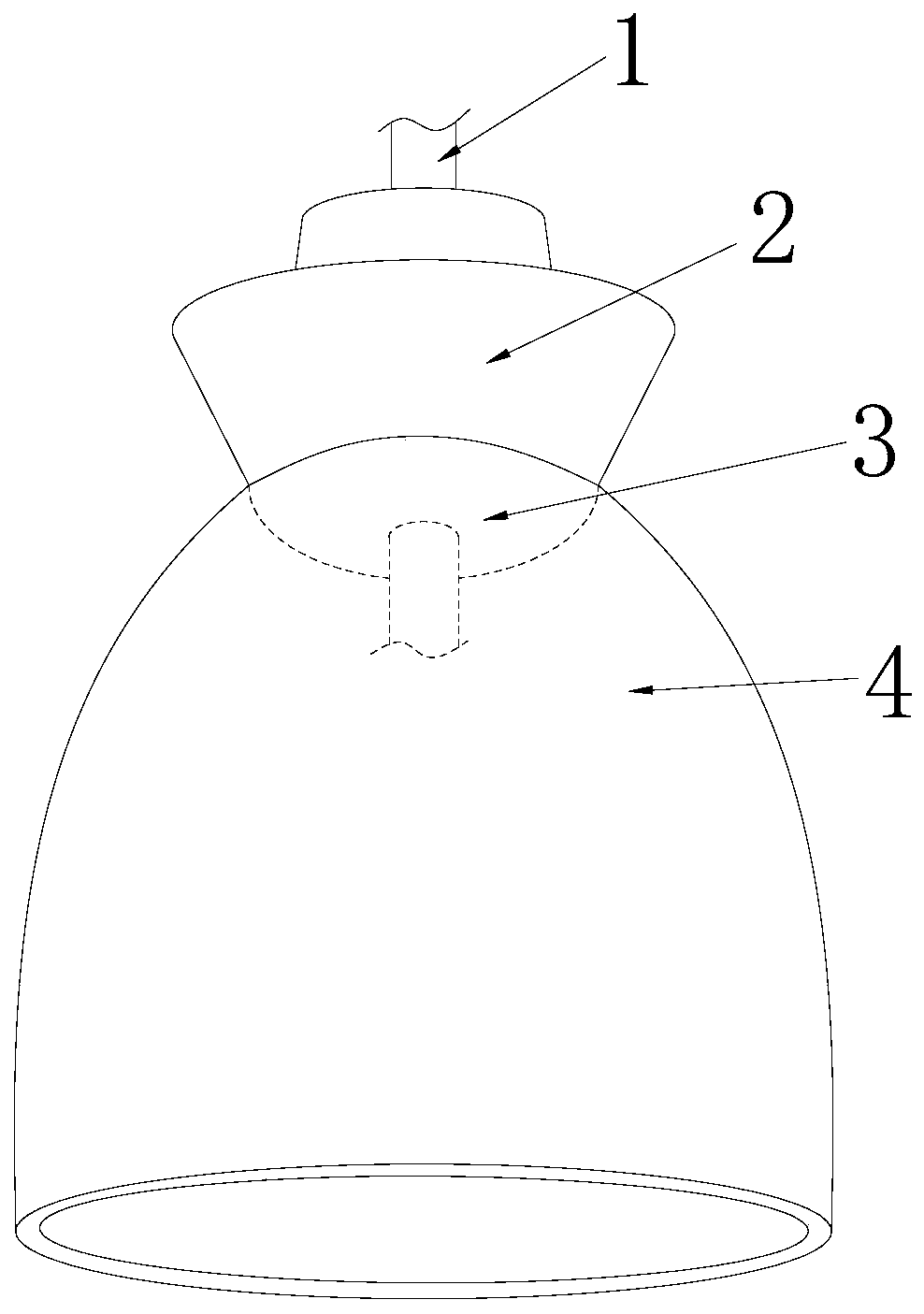

[0024] see Figure 1-Figure 6 , the present invention provides a built-in drive power supply LED pendant lamp, its structure includes a suspender 1, a connecting seat 2, a heat dissipation device 3, and a lampshade 4, the suspender 1 is fixedly connected to the connecting seat 2, and the connecting seat 2 is located on the hanging Between the rod 1 and the lampshade 4, the connecting seat 2 is installed on the top of the lampshade 4, the heat dissipation device 3 is installed in the inner cavity of the connecting seat 2, and the end of the suspender 1 away from the connecting seat 2 is fixedly connected to the ceiling, so The inner cavity of the connecting seat 2 communicates with the lampshade 4;

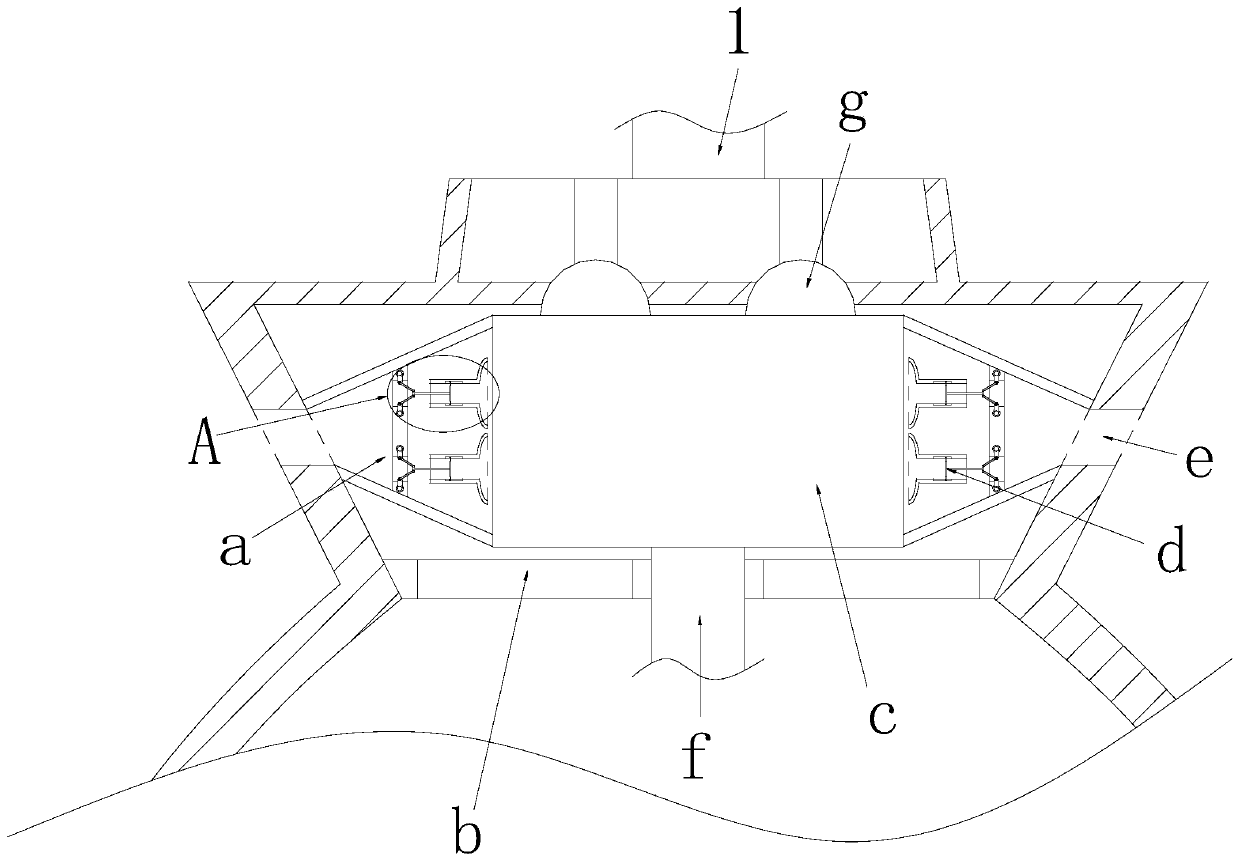

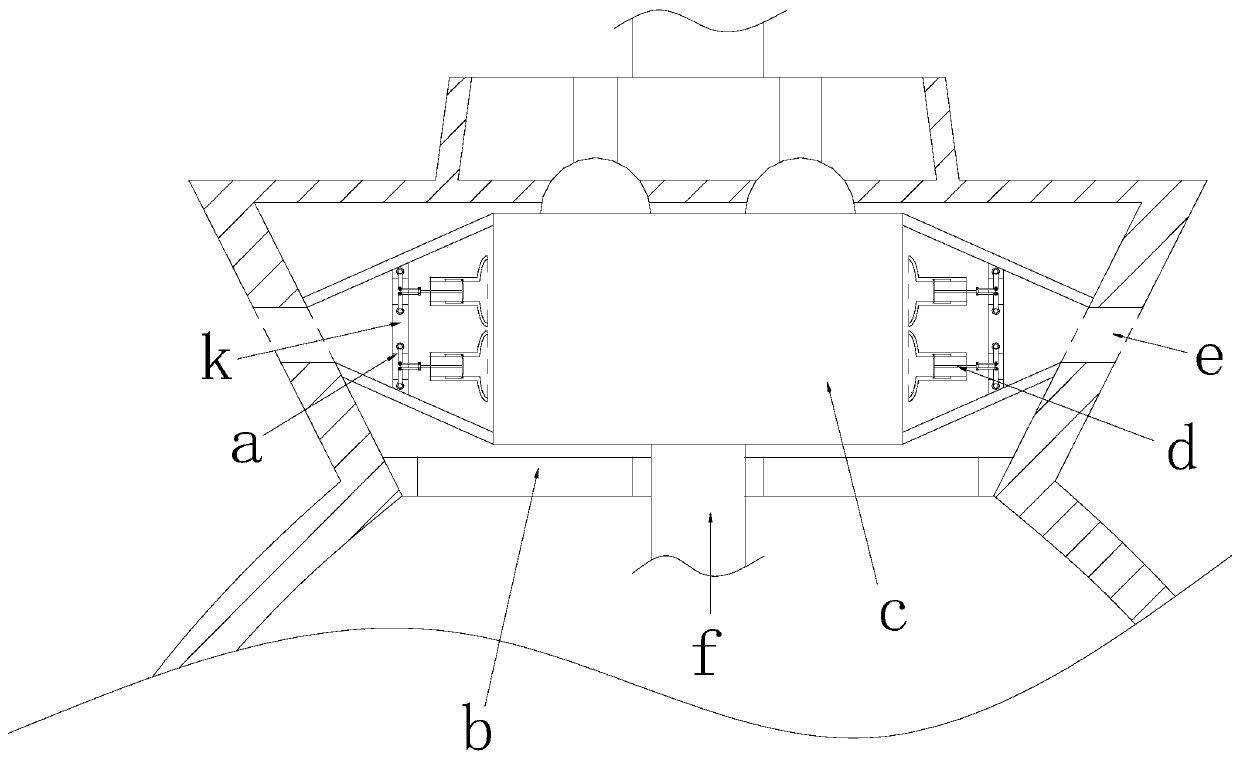

[0025] The heat dissipation device 3 is composed of a heat dissipation channel a, an isolation mechanism b, a driving power supply c, a heat dissipation mechanism d, a heat dissipation port e, a connecting wire f, and a fixing block g. There are two heat dissipation channels a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com