Integrated monitoring system for tank car operating flow rate

A monitoring system and tanker technology, which is applied in the field of complete monitoring of tanker loading and unloading operations, can solve the problems of inability to verify, inability to look up accident history data, and inability to increase calculation functions, etc., to achieve accurate and safe flow rate control, facilitate follow-up viewing, and eliminate The effect of data errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

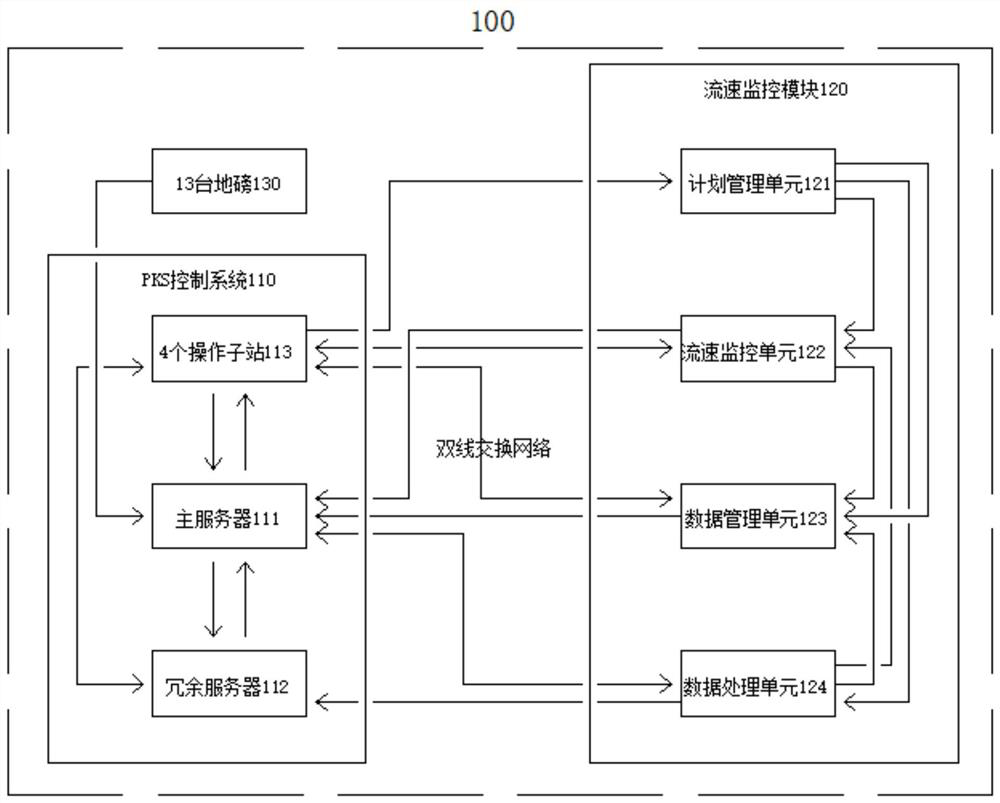

[0040] see figure 1 and figure 2 Shown is a specific embodiment of the tank truck operating flow rate integrated monitoring system described in this application. The tank truck operating flow rate integrated monitoring system 100 includes: a PKS system 110, a flow rate monitoring module 120, and 13 weighbridges 130, wherein,

[0041] The flow rate monitoring module 120 is coupled to the PKS system 110 through a two-wire switching network, and the flow rate monitoring module 120 includes a plan management unit 121, a flow rate monitoring unit 122, a data management unit 123, and a data processing unit 124. The software company issues ideas and requirements, and the software company modifies the PKS system 110 within the scope allowed by the certification. The flow rate monitoring module 120 is rooted in the main server 111 of the PKS system 110 and communicates with the PKS system 110. Its subunits assume different The function carries out data fetching communication separate...

Embodiment 2

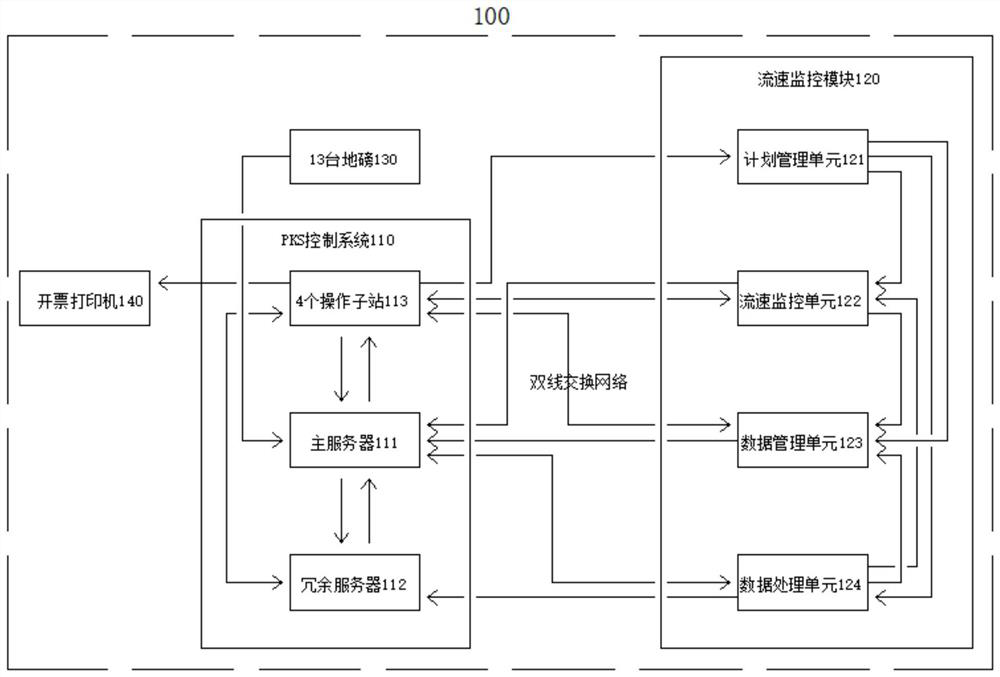

[0056] On the basis of embodiment 1, see image 3 and Figure 4 Shown is a practical embodiment of the integrated monitoring system for tank car operating flow rate described in this application.

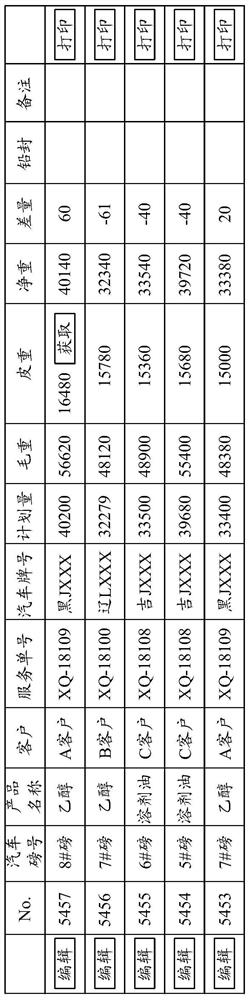

[0057] image 3 The unloading status record table (only exemplifying the unloading data on several weighbridges) derived for the data management unit 123, image 3 The table includes the position of the tank car unloaded on different weighbridges, the name of the product to be unloaded, the name of the customer, the license plate number of the tank car, the amount of product to be unloaded (planned amount), and the total weight of the tank car (gross weight), tank car empty weight (tare weight), subtract the tare weight from the gross weight to get the actual unloaded product amount, and subtract it from the planned amount to get the difference between the two, so as to check whether the product is completely unloaded . This table can also be modified manually, just click the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com