fiber optic cable

A technology of optical fiber cable and optical fiber, which is applied in the field of optical fiber cable, can solve the problems of large untwisting force and the inability of the optical fiber unit to keep being twisted, and achieve the effect of inhibiting movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

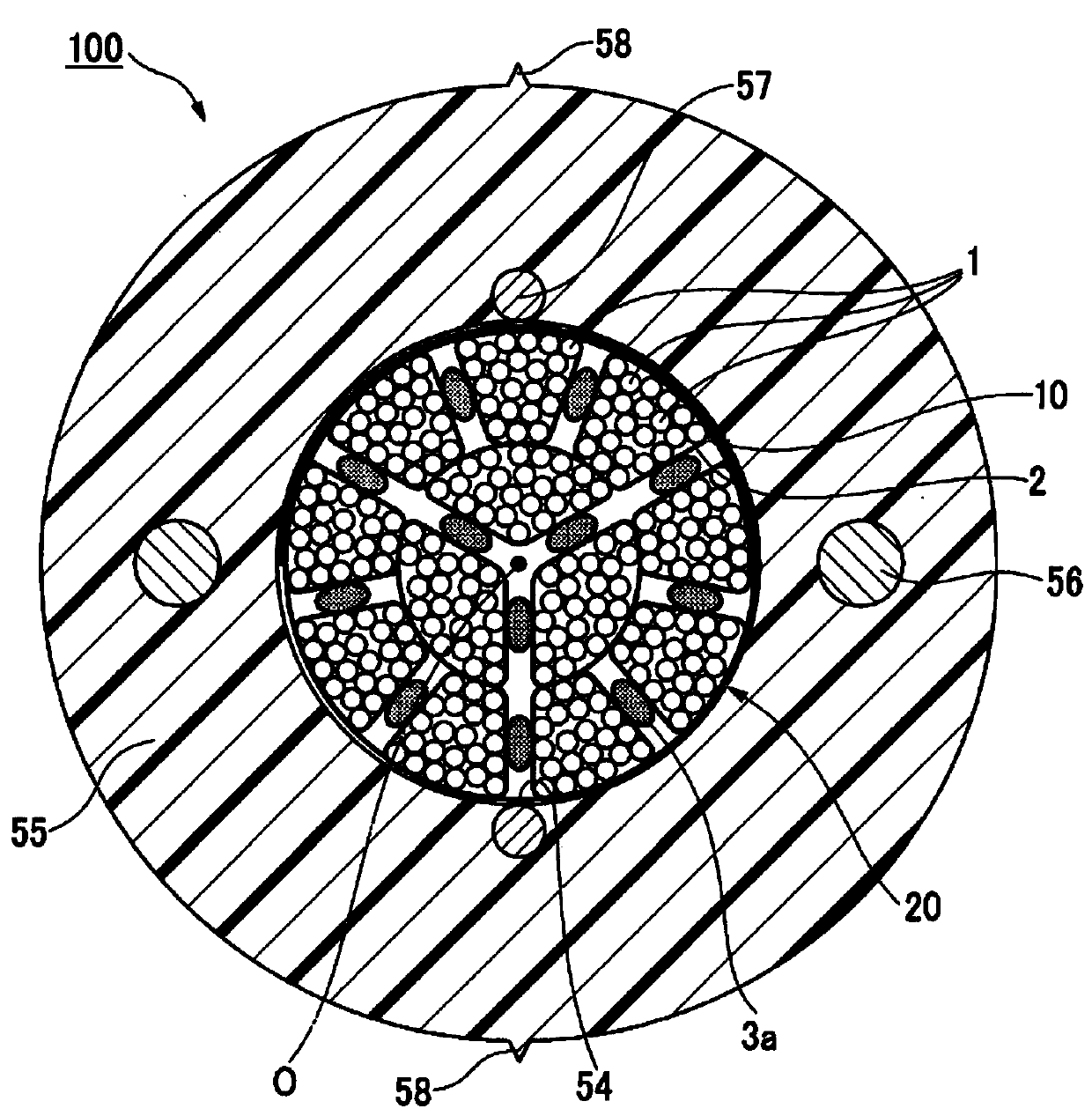

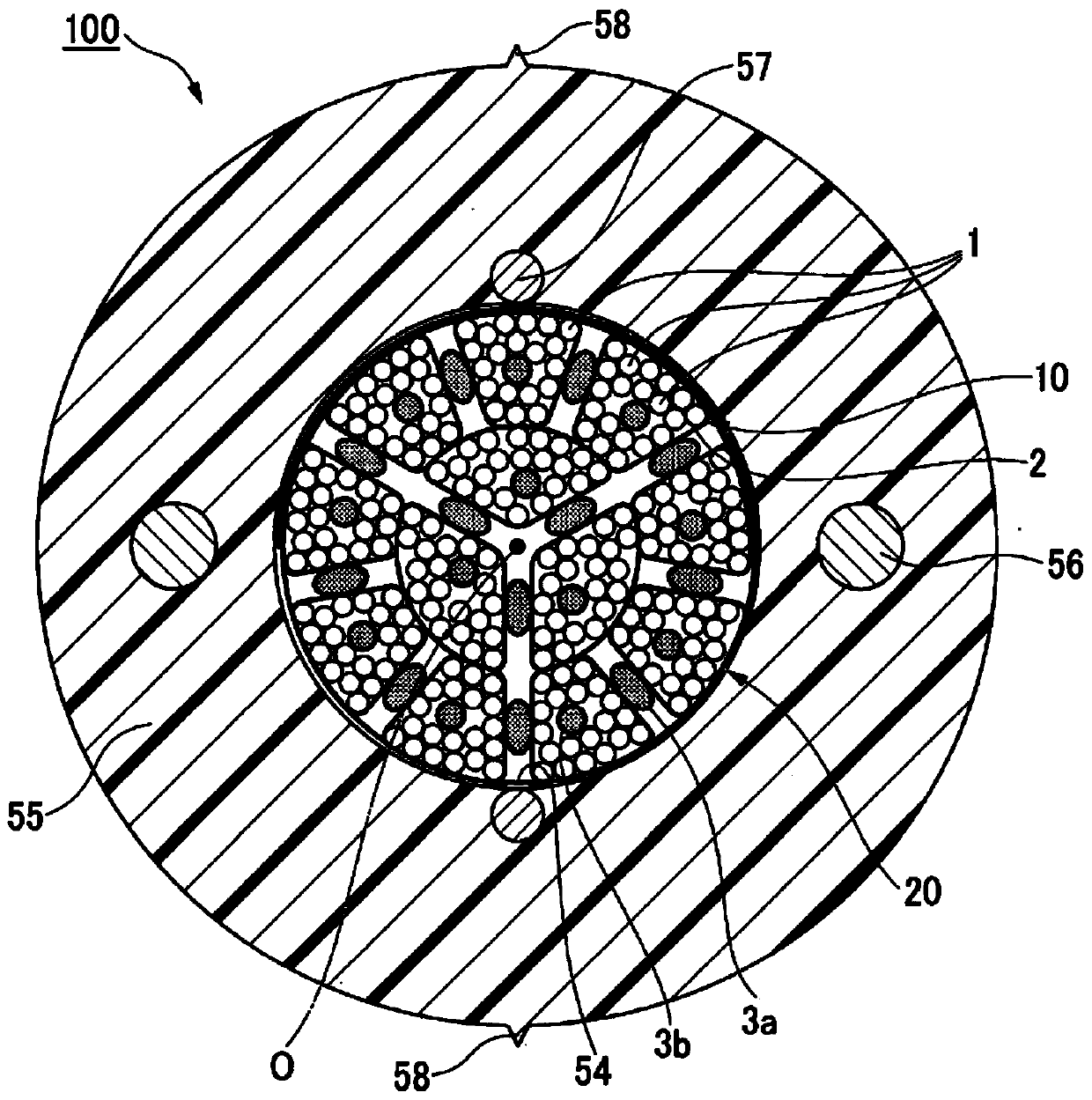

[0011] Below, refer to figure 1 The structure of the optical fiber cable according to this embodiment will be described.

[0012] In addition, in figure 1 Among them, the scale is appropriately changed according to the actual product so that the shape of each component can be recognized.

[0013] Such as figure 1 As shown, the optical fiber cable 100 includes: a core 20 having a plurality of optical fiber units 10; a sheath 55 that accommodates the core 20 inside; and a pair of tensile members 56 (tension members) embedded in the sheath 55 and a To line body 57.

[0014]

[0015] Here, in the present embodiment, the optical fiber unit 10 extends along the central axis O. As shown in FIG. The direction along the central axis O is referred to as the longitudinal direction. A section perpendicular to the central axis O of the optical fiber cable 100 is called a cross section.

[0016] In addition, in cross section ( figure 1 ), the direction intersecting the central axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com