Integrated automatic assembling equipment of clamping-pressing type aluminum plastic pipe joint

An automatic assembly, aluminum-plastic pipe technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of automatic processing and assembly difficulty, and achieve the effect of simple and reasonable structure design, stable and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

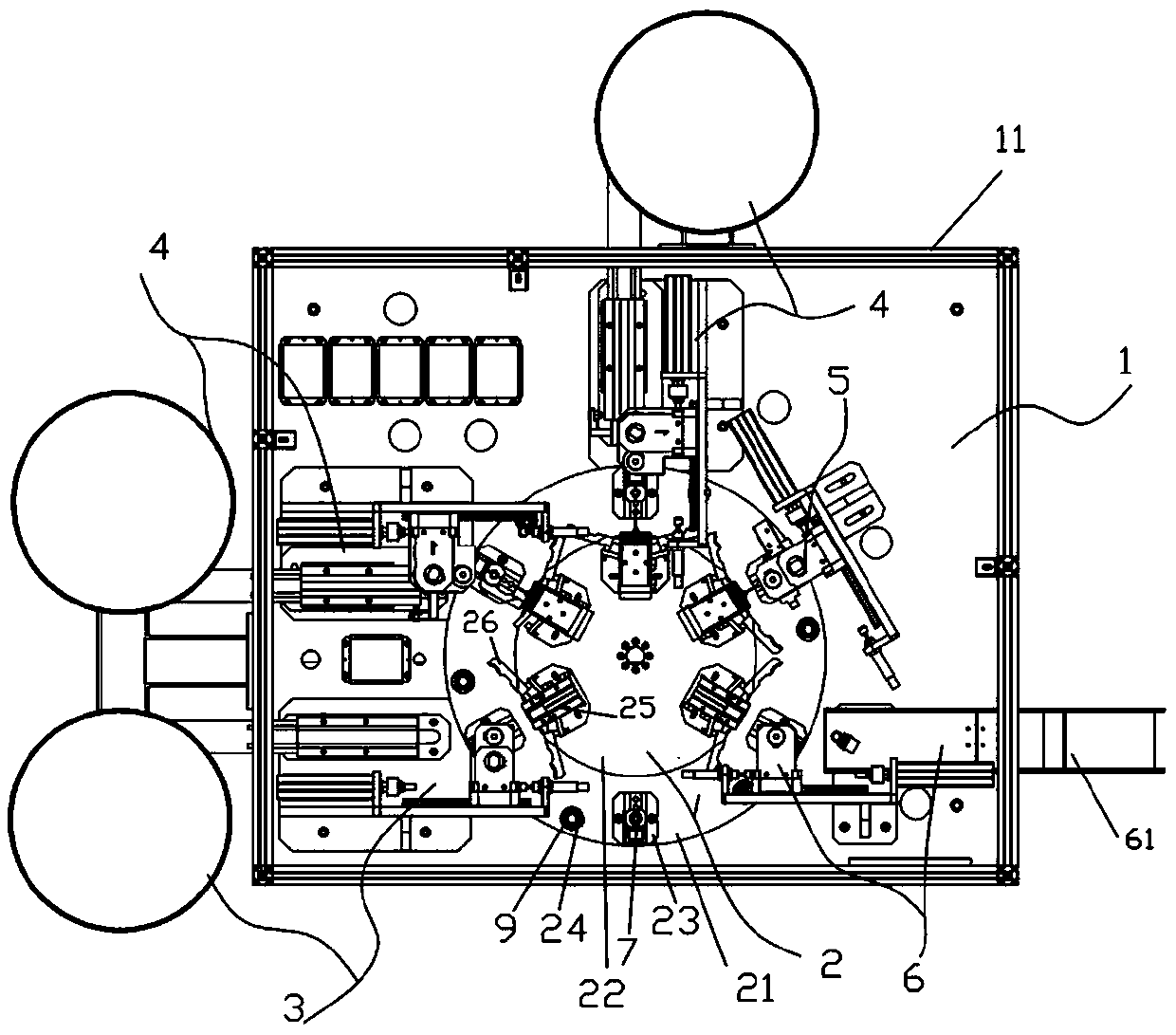

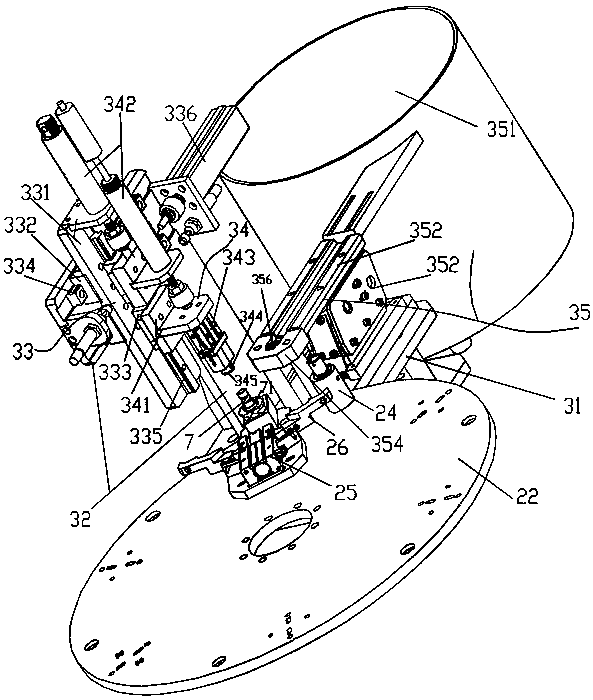

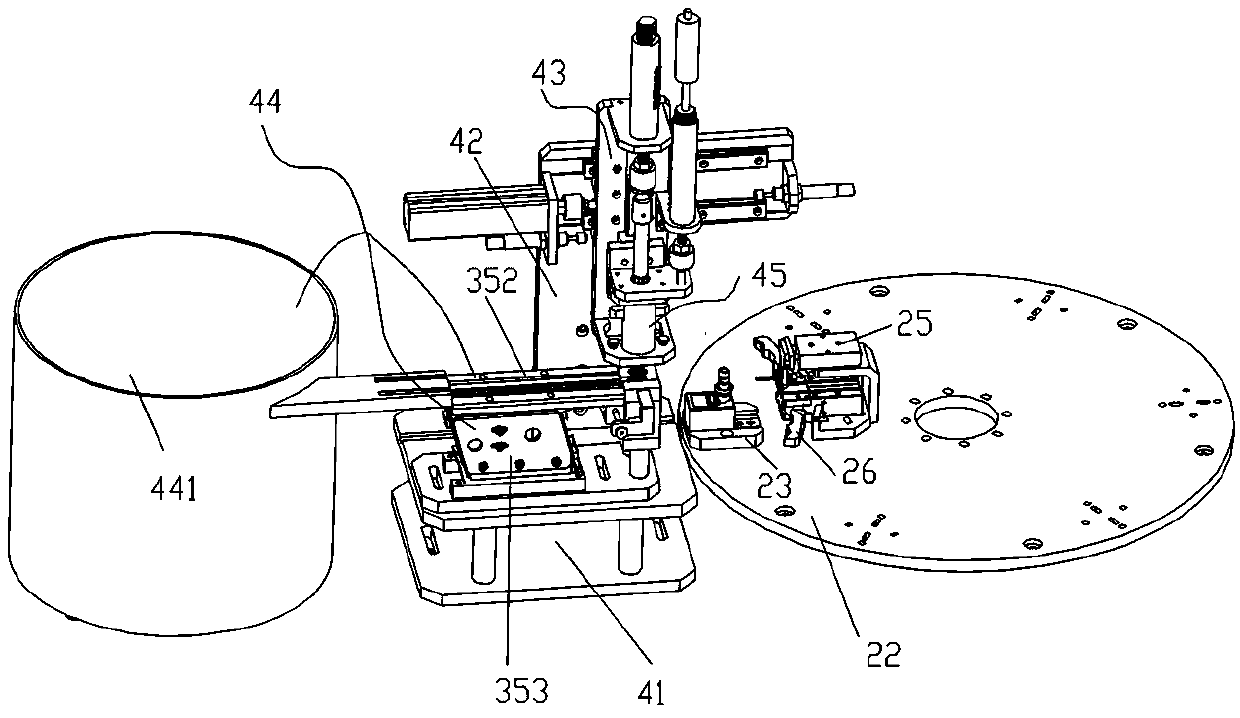

[0071] Such as Figure 1-Figure 6 As shown, an integrated automatic assembly equipment for press-type aluminum-plastic pipe joints, including a frame 1, a turntable work surface assembly 2, a plastic ring assembly part 3, a sealing ring assembly part 4, a cylinder liner assembly part 5, a discharge Component 6;

[0072] The frame 1 is a vertical cabinet, its upper surface is arranged horizontally, and a turntable worktable assembly 2 is arranged in the middle of its up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com