Assembly method of modified battery

An assembly method and battery technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complicated assembly process, increase design cost and inventory cost, and reduce design cost and inventory cost. Cost, simple effect of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A kind of assembling method of making D2000mAh refitting nickel-hydrogen battery, its specific steps are as follows:

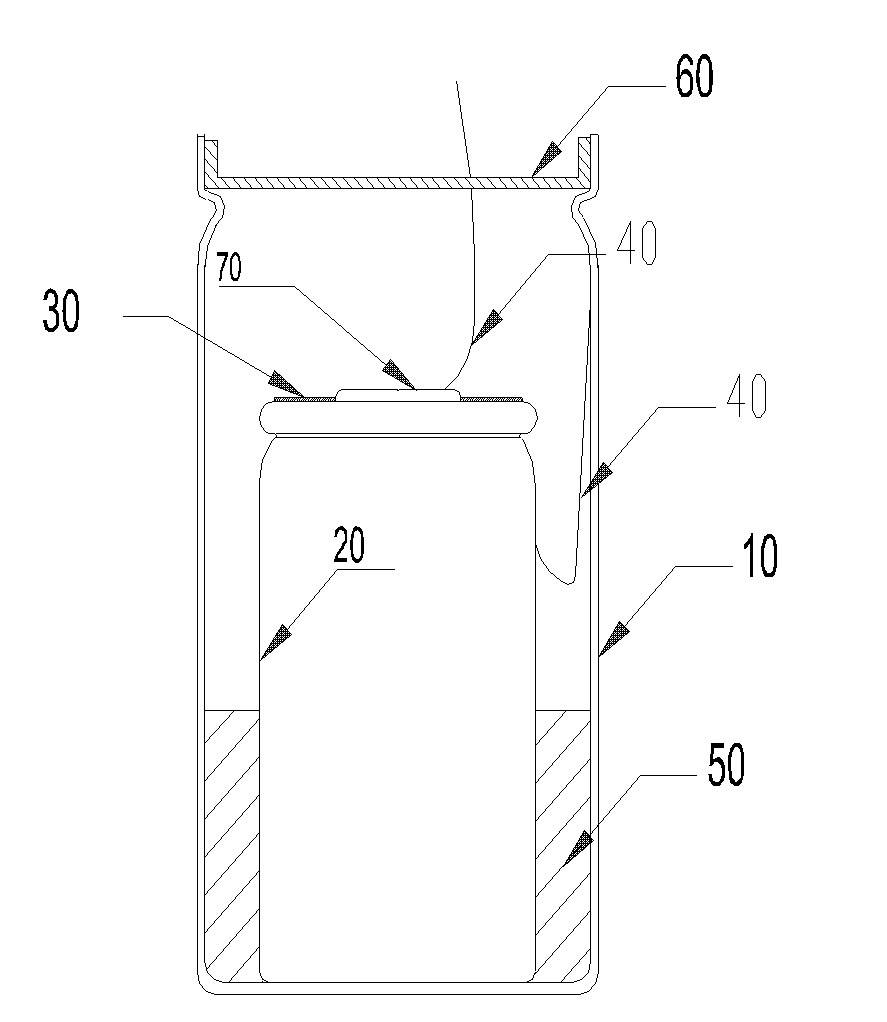

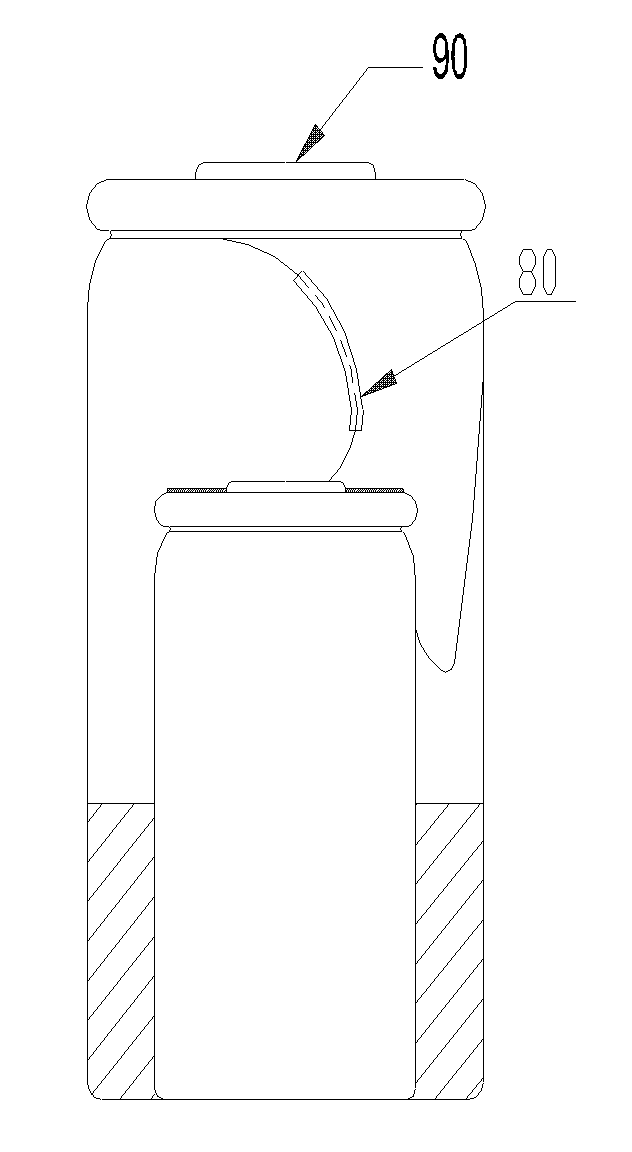

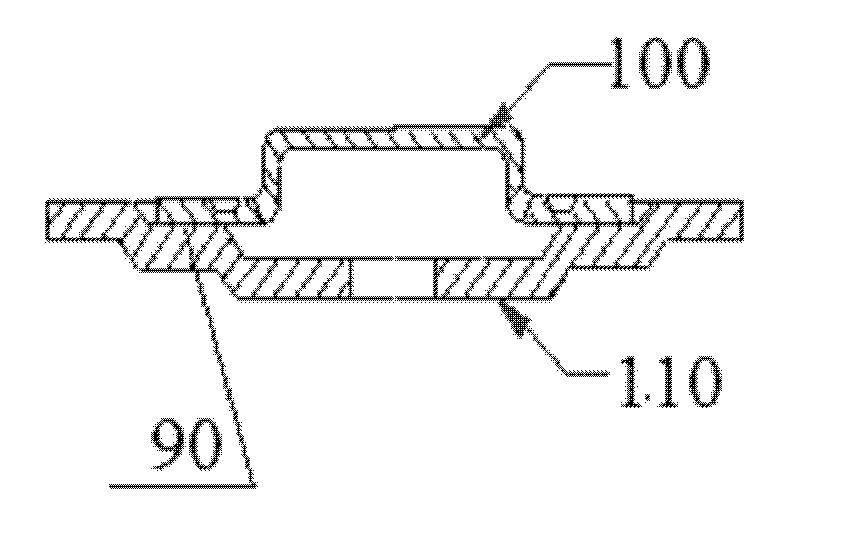

[0013] combine figure 1 with figure 2 , in the D-shaped steel shell 10, place a battery 20 of SC2000mAh, a surface pad 30 is placed on the head of the SC2000mAh battery, a nickel strip 40 is spot-welded on the outer wall of the battery 20 and the top of the cap, and then the SC2000mAh battery 20 is put into In the D-shaped steel shell 10, inject liquid AB glue into the D-shaped steel shell (AB glue is a special adhesive adhesive produced by Shenzhen Tianningda Adhesive Technology Co., Ltd., the models are N-818A and N-818B) 50, The depth of the glue liquid level can be 1 / 4~1 / 3 of the D-shaped battery shell. After the AB glue 50 is solidified, spot weld the other end of the nickel strip 40 connected to the outer wall of the SC2000mAh battery 20 to the D-shaped steel shell 10. Below the part, the D-shaped steel shell 10 with the SC2000 battery 20 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com