An encoder automatic assembly machine with a shaft core and a retaining ring

An automatic assembly machine and encoder technology, applied in transportation and packaging, conveyor objects, etc., can solve problems such as hindering cost reduction, poor reliability, easy deformation of circlips, etc., to ensure product quality, process automation, and solve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

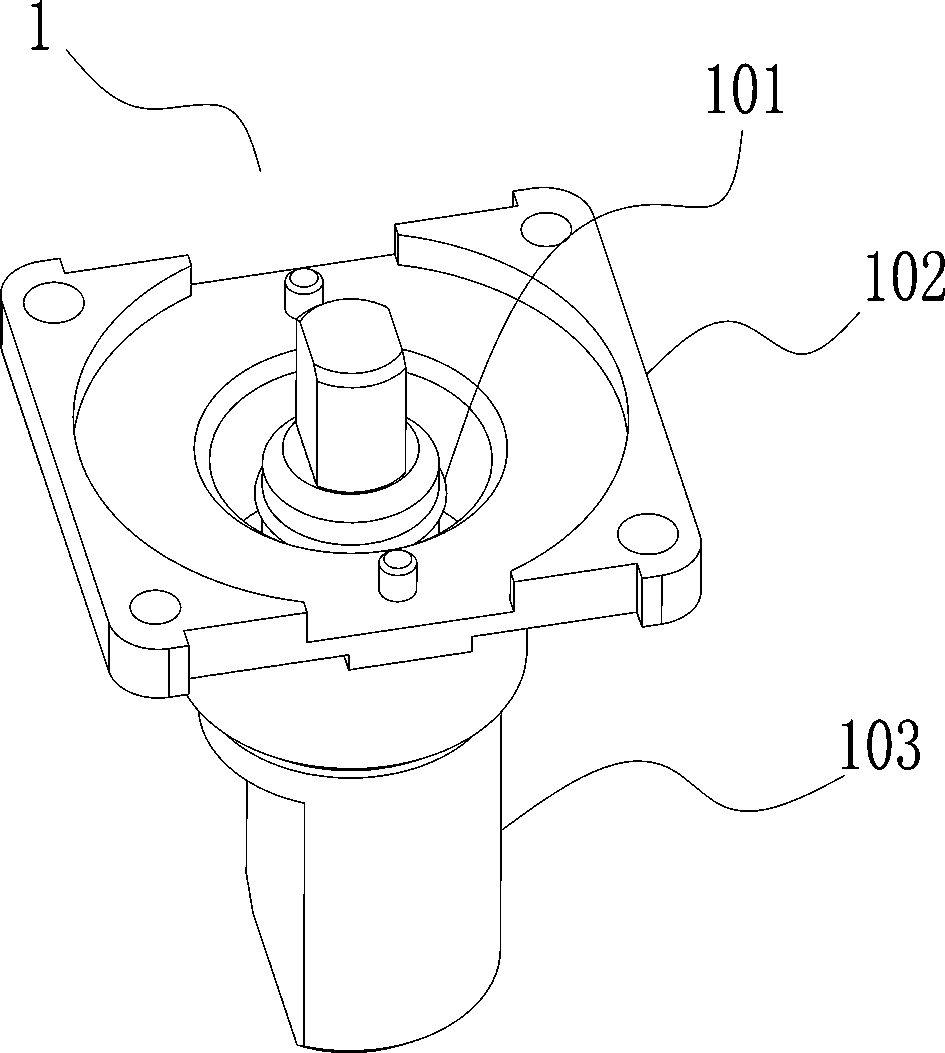

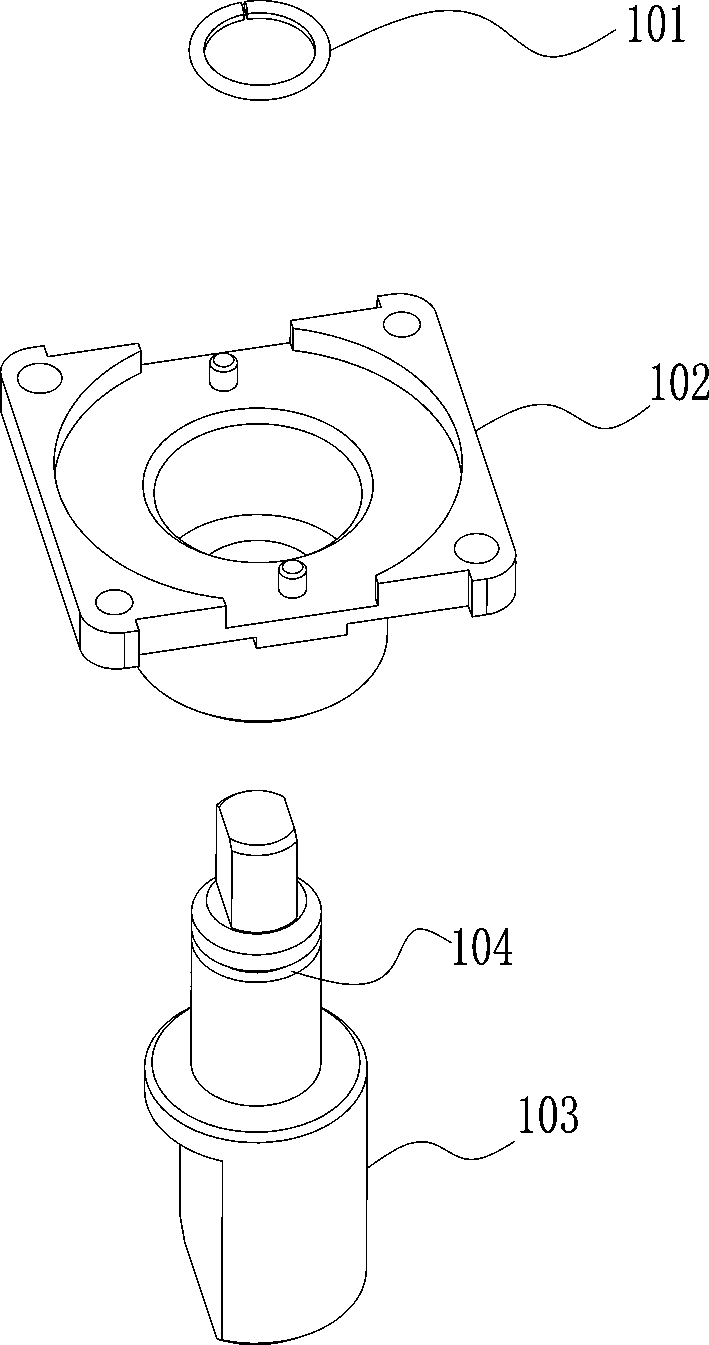

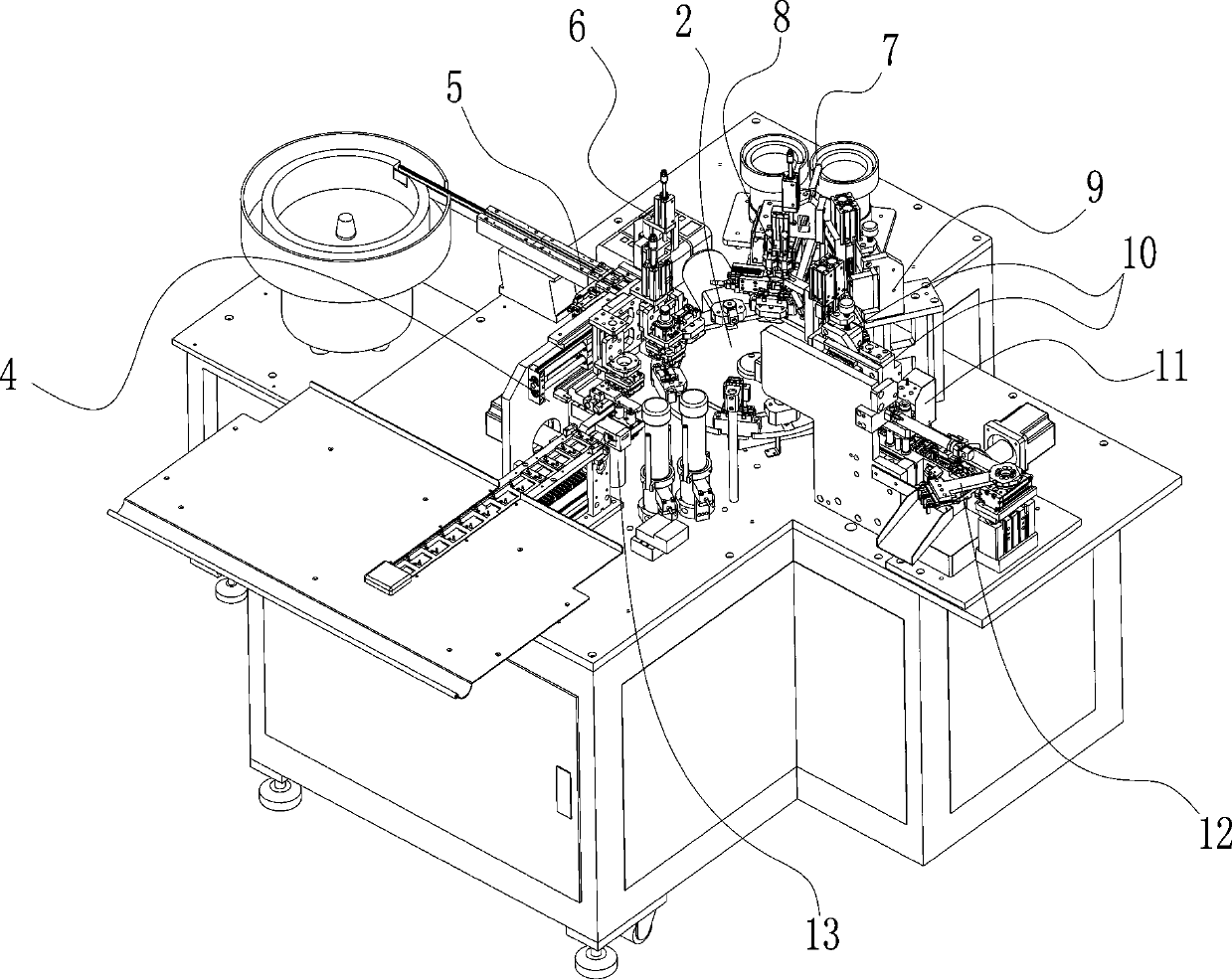

[0047] like Figure 1-13As shown, an encoder automatic assembling machine with a shaft core and a circlip is used to complete the assembly of the encoder 1 composed of at least a shaft core 101, a shaft sleeve 102 and a circlip 103. The assembling machine includes multiple On the multi-station turntable 2, double positioning fixtures 3 are arranged at equal intervals along the rotation direction on the multi-station turntable 2, and along the rotation direction of the multi-station turntable 2 are sequentially provided with a shaft core device 4, a vibration feeding device 5, and a shaft sleeve device 6 , the circlip device 8, the riveting circlip device 9, the secondary riveting circlip and the product taking device 10, the detection device 11 and the unloading device 12, the aforementioned devices realize the loading of the shaft core on the double position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com