Method and device for prying up BGA in dyeing test

A technology of guide bolts and printed boards, applied in hand-held tools, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

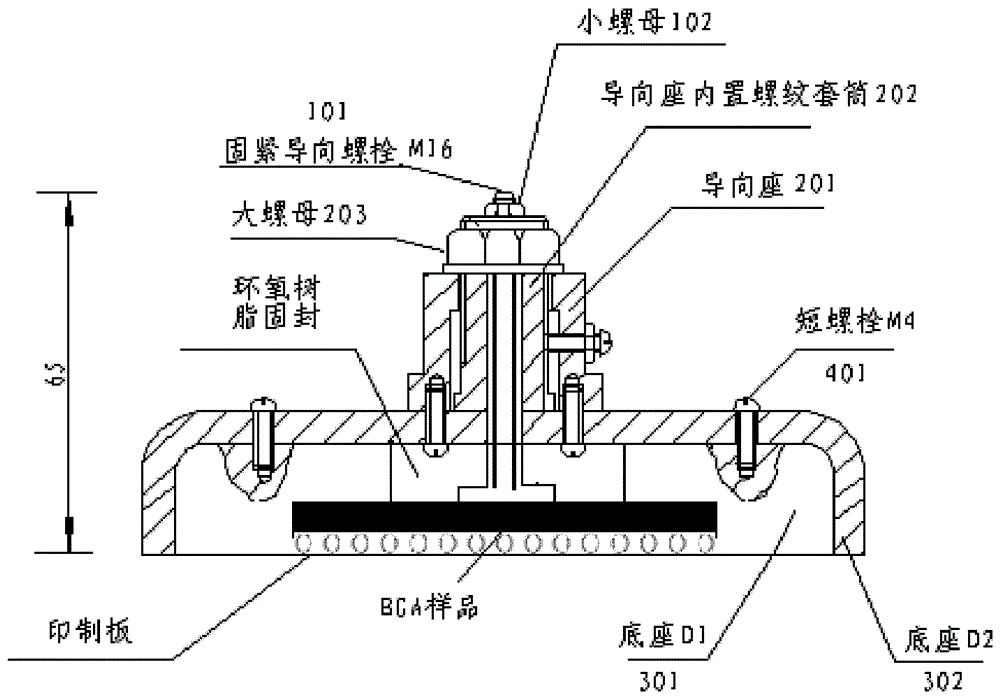

[0015] see figure 1 , the device for prying up the BGA in the dyeing test of the present invention comprises a fastening guide bolt 101, a small nut 102, a guide seat 201, a built-in threaded sleeve 202), a large nut 203, a first base 301, a second base 302, seven Short M4 bolts 401; between the guide seat and the first base, between the first base and the second base are connected by short M4 bolts, the guide seat is stacked above the first base, and the built-in threaded sleeve is arranged in the guide seat and It can move up and down. The built-in threaded sleeve is connected with the first base. The tightened guide bolts pass through the built-in threaded sleeve and the first base in turn. A small nut is placed on the exposed tail of the bolt, and the small nut is placed above the built-in threaded sleeve, and a large nut is nested outside the built-in threaded sleeve. Abutting against the printed board, the second base is connected in the first base and abutted against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com