Portable cutting edge protector

A protector and portable technology, applied in grinding/polishing hand tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of operator's physical harm, scrapped hairdressing scissors, worn-out tooth structure, etc. High sharpening precision, avoiding tool damage and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

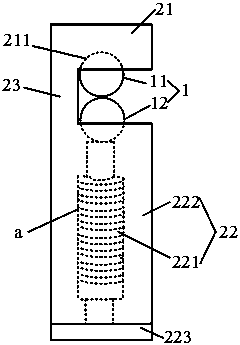

[0029] like figure 1 As shown, the portable edge protector of the embodiment of the present invention comprises:

[0030] A set of edge protection units 1 , the edge protection unit 1 includes a first sharpening sphere 11 and a second sharpening sphere 12 that are tangential. The specifications of the first sharpening sphere 11 and the second sharpening sphere 12 are not limited, and the ball diameters of the first sharpening sphere 11 and the second sharpening sphere 12 can be the same or different, according to actual conditions, such as cutting tools specifications for design.

[0031] The material of the first sharpening sphere 11 and the second sharpening sphere 12 is preferably zircon material with high hardness. Of course, the usual sharpening material can also be used, but the usual sharpening material is more consuming.

[0032] A fastening device, the fastening device fixes the first sharpening sphere 11 and the second sharpening sphere 12 so that the first sharpen...

no. 2 example

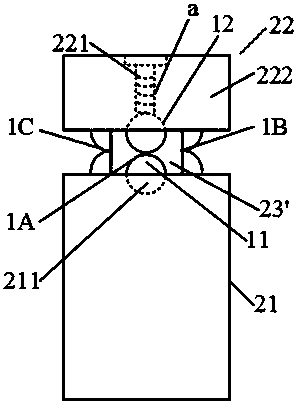

[0040] like figure 2 As shown, the portable edge protector of the embodiment of the present invention comprises:

[0041] At least two groups of cutting edge protection units, for example, may include three groups of cutting edge protection units 1A, 1B and 1C, each group of cutting edge unit structure is the same as the cutting edge unit structure of embodiment 1, that is, it includes a tangential first sharpening sphere 11 and the second sharpening spheroid 12.

[0042] The specifications of the first sharpening sphere 11 and the second sharpening sphere 12 are not limited, and the ball diameters of the first sharpening sphere 11 and the second sharpening sphere 12 can be the same or different, according to actual conditions, such as cutting tools According to the specification and design, the material of the first grinding ball 11 and the second grinding ball 12 in the embodiment of the present invention is preferably zircon with relatively high hardness.

[0043] The fast...

no. 3 example

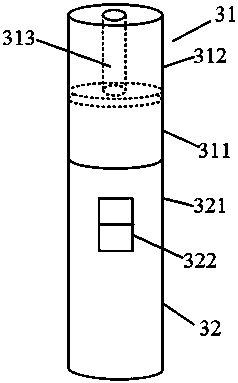

[0052] In the structure of the portable edge protectors of the first embodiment and the second embodiment, a vibrating device can be further provided to drive the fastening device and the edge protection unit to vibrate to accelerate grinding. The portable edge protector of the first embodiment will be described below as an example.

[0053] like image 3 As shown, the vibrating device includes a detachably connected working part 31 and a handle part 32 , and the working part 31 drives the fastening device and the edge protection unit 1 to vibrate.

[0054] The working part 31 can adopt a columnar structure, such as a nylon rod. The working part 31 includes a motor part 311 and a mounting part 312. The motor part 311 and the mounting part 312 are isolated to prevent water from entering the motor part through the mounting part 312 and damaging the motor. The motor part 311 is provided with a vibration motor (not shown in the figure), and the type of the vibration motor is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com