Strong self-correction photoelectric sensor and using method thereof

A photoelectric sensor and sensor technology, applied in the field of sensors, can solve problems such as attenuation and affecting the use of industrial doors, and achieve the effect of increasing sensitivity, optimal sensitivity, and realizing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

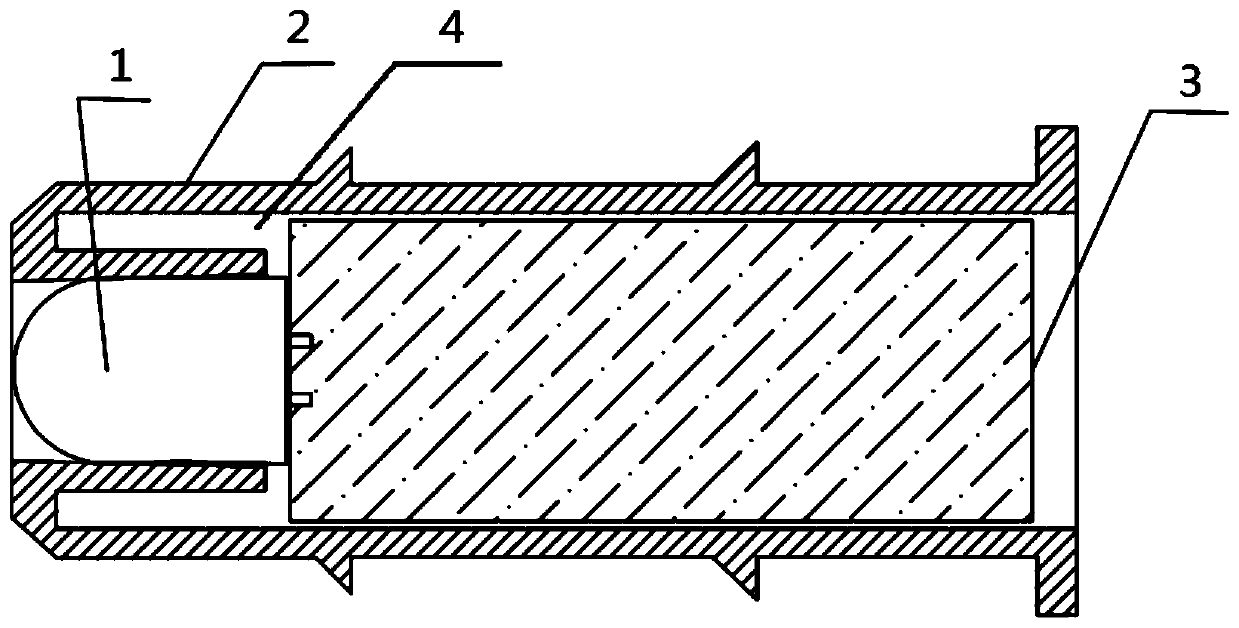

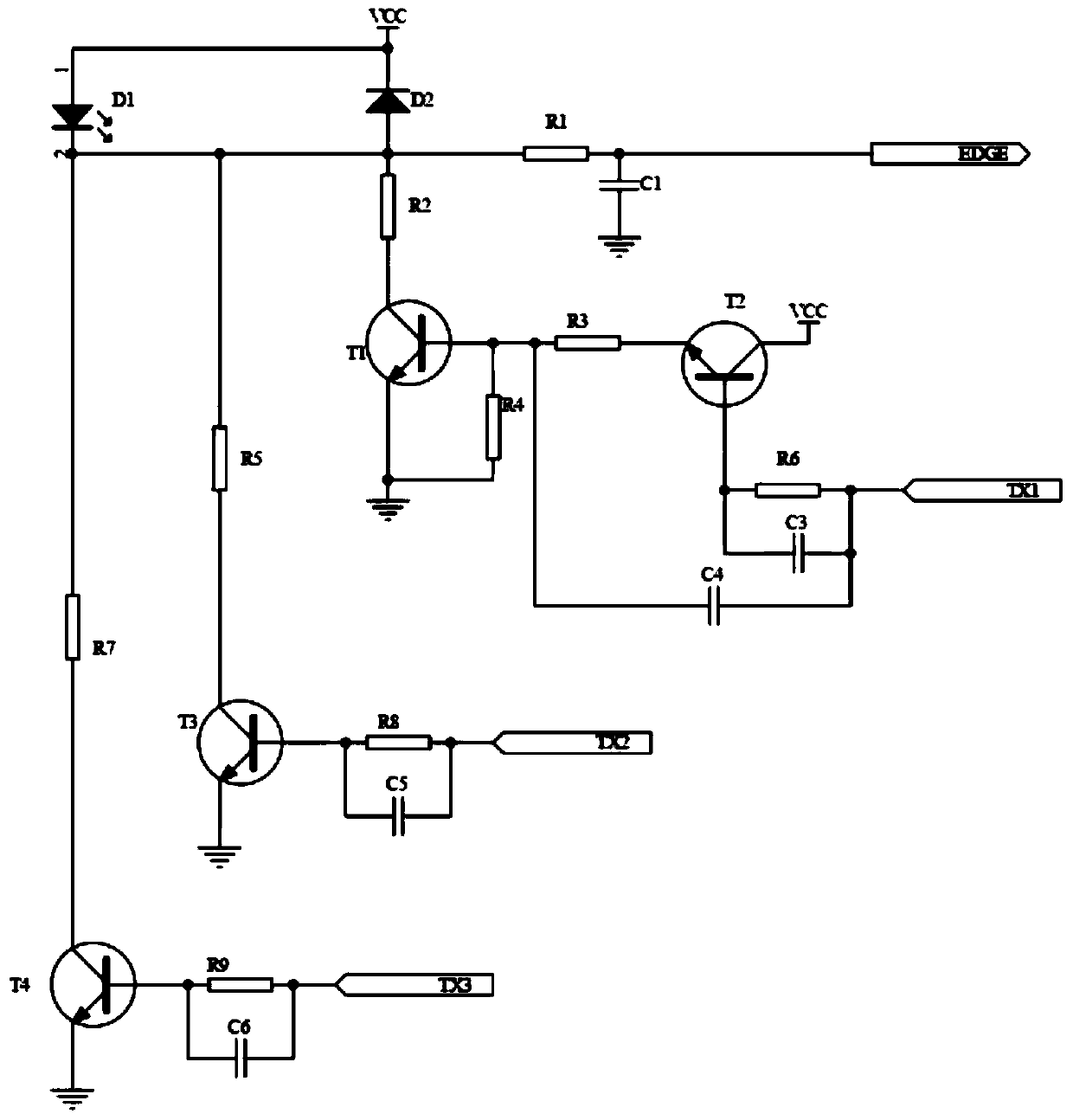

[0028] refer to Figure 1-4 , a photoelectric sensor with strong self-calibration, including a sensor body 4, the sensor body 4 includes a sensor housing 2, the sensor housing 2 is made of plastic material, a circuit board 3 is installed inside the sensor housing 2, and one side of the circuit board 3 is connected to a Transmitting and receiving tube 1, transmitting and receiving tube 1 includes a transmitting end and a receiving end, the transmitting end includes a D1 transmitting tube, the D1 transmitting tube is an infrared transmitting tube, and the D1 transmitting tube includes three pulse signals of transmitting 1, transmitting 2 and transmitting 3;

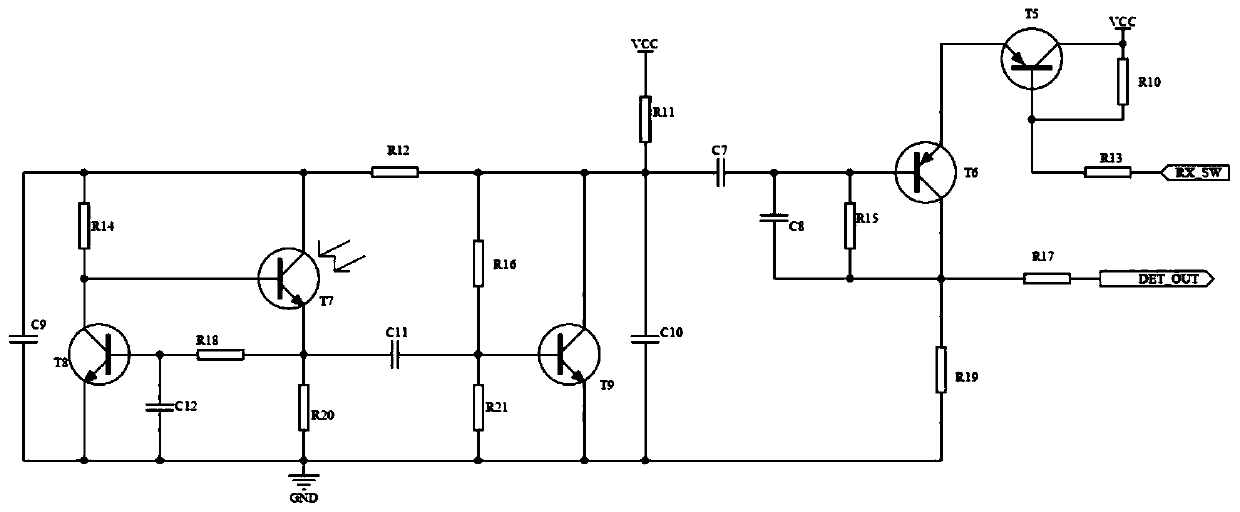

[0029] Among them, the frequencies of pulse signals transmitted by transmission 1, transmission 2 and transmission 3 are different; the receiving end of transmission and reception tube 1 adopts high-sensitivity triode T7, and adopts a high-magnification amplification circuit;

[0030] It should be noted that the circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com