Control method, device, equipment for multiple stages of coal feeders and readable storage medium

A control method and technology for a coal feeder, applied in the field of electric power, can solve the problems of instantaneous coal flow congestion, affecting the stability of the thermal power generation coal feeding system, and coal flow surging phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

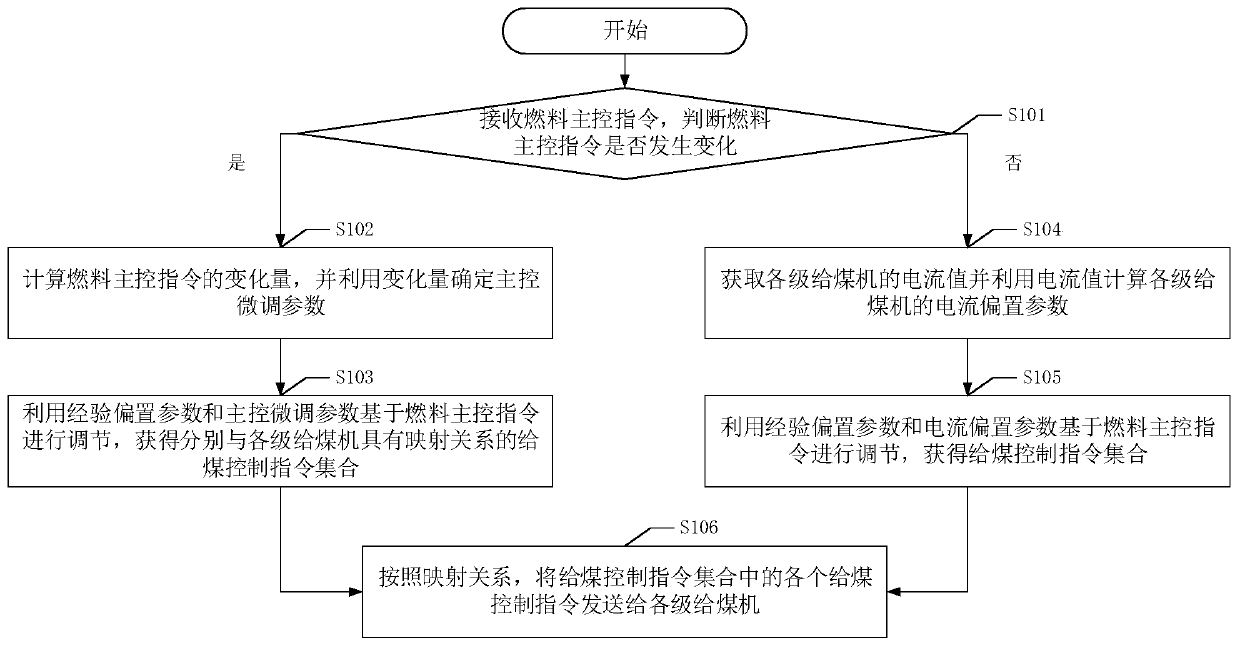

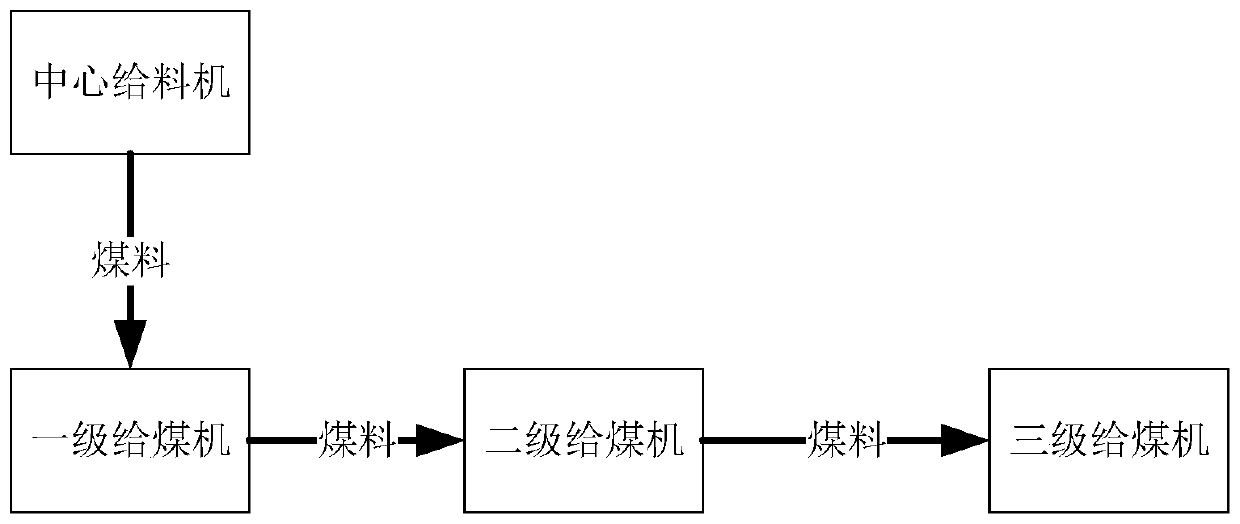

[0049] Please refer to figure 1 , figure 1 It is a flow chart of a multi-stage coal feeder control method in an embodiment of the present invention. The method can be applied to the coal material control system in a coal-fired thermal power generating set. The method includes the following steps:

[0050] S101. Receive a fuel master control command, and determine whether the fuel master control command has changed.

[0051] The fuel master control command can be a control command sent by the master control center. Specifically, the fuel master control command can carry the amount of coal and the duration of coal supply, or directly carry the size of the coal flow (unit ton / hour). After receiving the coal master control instruction, the fuel master control instruction can be compared with the fuel master control instruction received last time to determine whether the fuel master control instruction has changed. Specifically, it is to judge whether the coal amount and the coal...

Embodiment 2

[0091] Corresponding to the above method embodiment, the embodiment of the present invention also provides a multi-stage coal feeder control device, the multi-stage coal feeder control device described below and the multi-stage coal feeder control method described above can correspond to each other refer to.

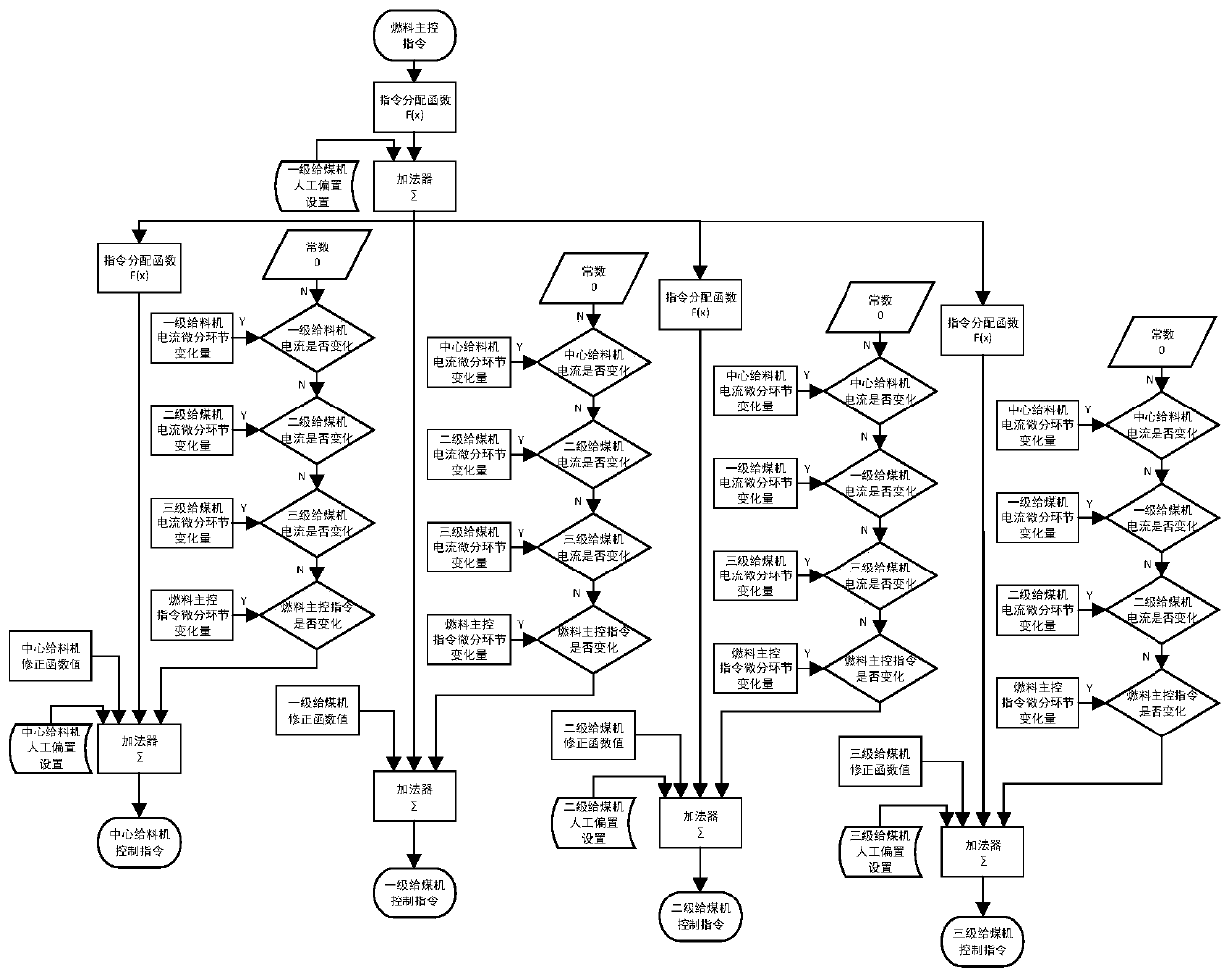

[0092] see Figure 4 As shown, the device includes the following modules:

[0093] The instruction monitoring module 101 is used to receive the fuel main control instruction and judge whether the fuel main control instruction changes;

[0094] The dynamic adjustment module 102 is used to calculate the variation of the fuel main control instruction if the fuel main control instruction changes, and use the variation to determine the main control fine-tuning parameters; use the empirical bias parameters and the main control fine-tuning parameters to Make adjustments to obtain a set of coal feeding control commands that have a mapping relationship with coal feeders at all ...

Embodiment 3

[0106] Corresponding to the above method embodiment, the embodiment of the present invention also provides a multi-stage coal feeder control device, a multi-stage coal feeder control device described below and a multi-stage coal feeder control described above The methods can be referred to each other.

[0107] see Figure 5 As shown, the multi-stage coal feeder control equipment includes:

[0108] memory D1 for storing computer programs;

[0109] The processor D2 is used to implement the steps of the multi-stage coal feeder control method in the above method embodiment when executing the computer program.

[0110] Specifically, please refer to Figure 6, is a specific structural diagram of a multi-stage coal feeder control device provided in this embodiment. The multi-stage coal feeder control device may have relatively large differences due to different configurations or performances, and may include one or more processors (central processing units, CPU) 322 (eg, one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com